- Best Practices for Equipment O&M

-

O&M Best Practice Issue Discussions

- Advanced Maintenance Approach: Reliability Centered Maintenance

- Applying Key Performance Indicators

- Comprehensive O&M Program

- Contract Challenges and Improvements

- Cybersecurity for O&M Systems

- Existing Building Commissioning Procurement

- Healthy Building O&M

- Integrating and Analyzing Building Information to Support O&M

- Maintenance Approaches

- OMETA: An Integrated Approach to Operations, Maintenance, Engineering, Training, and Administration

- Prioritizing O&M Actions

- Re-tuning Buildings

- Tools

- Glossary

Re-tuning Buildings

Table of Contents

- Introduction

- Discussion

- Solutions and Actions

- Conclusions and Next Steps

- Additional Resources

- Definitions

- References

Introduction

This Best Practice provides an introduction to the Re-tuning of buildings (Re-tuning) by summarizing the approach, its outcomes, and applications. Facility managers often find themselves in a position of trying to provide for occupant comfort demands while also meeting energy efficiency goals to reduce operational cost. Management of facilities and equipment to achieve both of these goals could be contradictory and challenging. In addition, facility managers are working to address the Energy Information and Security Act of 2007 Section 432 (EISA 432) requirement to identify and assess recommissioning (ReCx) measures (or if the facility has never been commissioned, retrocommissioning (RCx) measures) as part of the necessary evaluation. The main purpose of the ReCx/RCx process is to make sure the equipment and systems operate according to the design conditions or current operational needs. The goal of Re-tuning is to optimize the operation of equipment and systems throughout the year to adjust to the actual demand.

For facilities with building automation systems (BASs) and minimal ReCx/RCx needs, Re-tuning may allow the facility managers to comply with the EISA’s commissioning requirement while delivering additional benefits through optimization that ReCx/RCx may not provide. Re-tuning efforts with federal agencies have resulted in:

- building energy savings typically ranging from 5 percent to 25 percent;

- energy cost savings on the order of $0.185/sf-year with a corresponding simple payback of 0.3–3.5 years; and

- thermal comfort through correction of faults and making airside systems responsive to specific zone demands.

While the ReCx/RCx process consists primarily of physical examinations of systems and components, Re-tuning is a systematic, data-driven process that aims to identify and correct operational inefficiencies and problems to reduce energy consumption through the BAS. Because the work is done through the BAS, Re-tuning does not replace ReCx/RCx of systems with substantial component-related issues and failures. This Best Practice discusses the basic principles of Re-tuning and its benefits, as well as Re-tuning as a subset of ReCx/RCx to address low-cost/no-cost operation and maintenance (O&M) needs.

Discussion

Facility managers face the multifaceted challenges of balancing occupants’ comfort level and energy-efficient equipment operation while working to address the O&M needs of their buildings. Measures taken to address the comfort levels and/or O&M-related operational modifications can often contradict the effort to reduce energy consumption and its associated cost. For example, it is common for building zone usage to evolve and change over time, which may add to zone HVAC loads or alter zonal needs and often causes comfort issues. The short-term solution to zoning-related comfort issues is typically the manual adjustment of zone temperature setpoints. Similarly, setpoint and scheduling changes may address O&M-related issues. For example, fans and heating coils may be left on and open throughout the winter months to prevent equipment components from freezing if freeze prevention control measures are not operating properly. With these manual adjustments to setpoint and scheduling left in place over time, equipment operates longer and better than required. While these measures can temporarily mitigate the occupants’ comfort issues and prevent equipment damage, operation tends to become more energy intensive and can shorten equipment life. Additionally, federal facility managers are tasked to comply with the requirements set by EISA 432. EISA 432 requires that quadrennial comprehensive energy and water evaluations “identify and assess recommissioning measures (or, if the facility has never been commissioned, retrocommissioning measures) as part of the necessary [facility] evaluation.” There are numerous approaches that may be applied to achieve EISA ReCx requirements.

ReCx and RCx refer to an equipment-by-equipment examination process to repair and recalibrate the equipment and components to make sure proper operation and functionality of systems. The cost and time required for these examination processes by commissioning professionals and implementing the repairs can be substantial and may not be necessary if the maintenance work is performed regularly by facility managers and operators. Also, the purpose of ReCx/RCx is to make sure the equipment operation meets the parameters set by design conditions or current operating needs—the process does not aim to optimize energy-efficient operation. For buildings and/or facilities equipped with BASs with minimal ReCx/RCx needs, Re-tuning can be used as a tool to identify and address low-cost/no-cost O&M needs. Re-tuning can also effectively optimize energy-efficient operation of buildings and zonal comfort based on four basic principles: turn it off, turn it down, mitigate simultaneous heating and cooling, and reduce infiltration and outdoor air. Re-tuning a building can result in measurable energy savings and occupant comfort improvements, with minimal investment and a short payback period.

Re-tuning as an Energy Savings Measure: Process and Outcomes

Building Re-tuning™ is a systematic process to identify operational problems by leveraging data collected from the BAS and correcting those problems at no or low cost (PNNL, 2018). In addition, the data collected is utilized to achieve the optimum equipment and system operation based on four basic principles:

- If you do not need it, turn it off.

- If you do not need it at full power, turn it down.

- Mitigate simultaneous heating and cooling.

- Reduce infiltration and outdoor air.

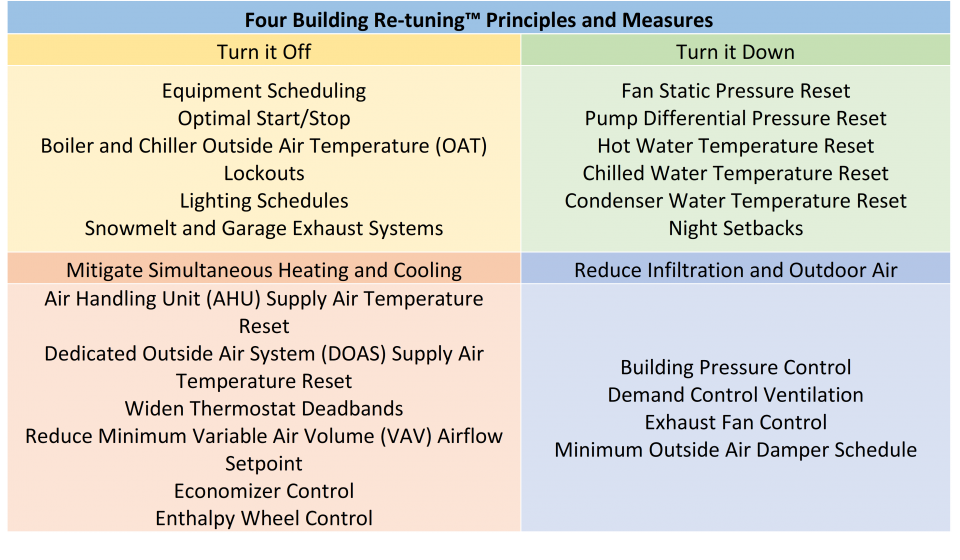

Equipment and systems are designed to provide heating, cooling, and ventilation to meet the peak cooling and heating load for a specified zonal occupancy level. ReCx/RCx processes make sure the operation of these design conditions, which typically involve constant setpoints for cooling, heating, and system pressure for air and/or hydronic systems. Equipment and systems, however, are not required to operate under the design condition outside of the peak summer and winter periods but are controlled to meet the maximum demand. For instance, the boilers may operate to generate 180 °F hot water throughout the year. A set of Re-tuning measures that aims to provide the right amount of heating and cooling according to the demand was developed by PNNL and is categorized based on four basic principles (Table 1).

Table 1. Four principles of Building Re-tuning™ and Re-tuning measures

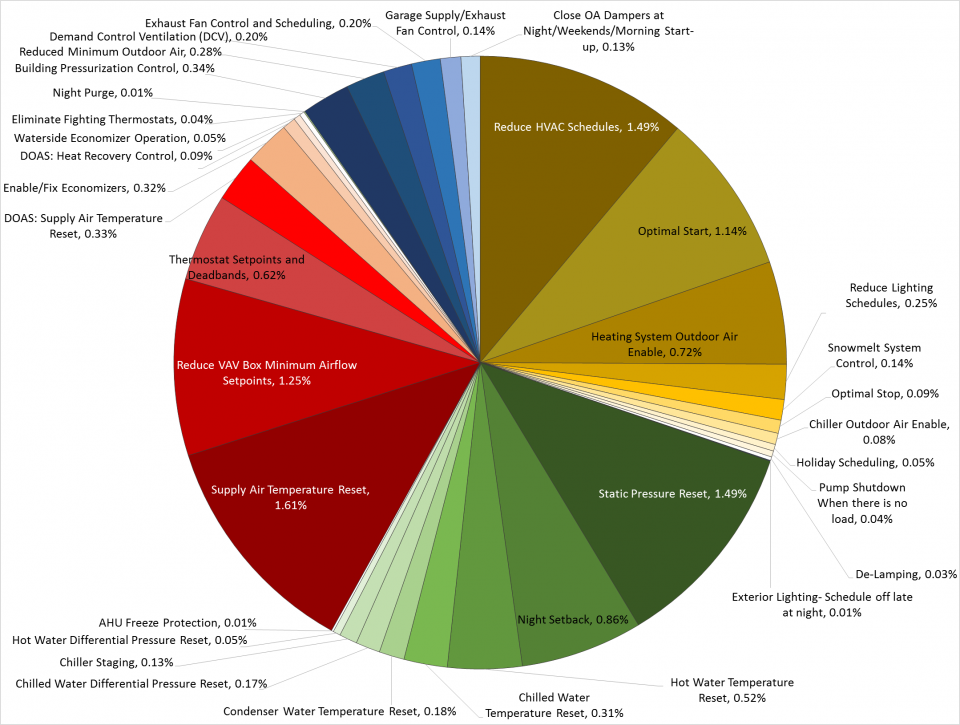

These measures are proven to provide significant energy savings. When applied in combination, the energy savings achieved are typically between 5 percent and 25 percent. The data collected based on the Building Re-tuning™ performed by PNNL at General Services Administration (GSA) facilities over the past 10 years indicate a total combined savings of 13.4 percent at over 80 facilities. Figure 1 shows the estimated allocations of the savings from the principle Building Re-tuning™ categories. Figure 2 dissects the total energy savings of 13.4 percent into savings realized by individual measures.

All four measure categories contribute significantly to the savings, with most savings generated by the “mitigate simultaneous heating and cooling” methodology, which minimizes the overcooling of an airstream followed by re-heat that can occur in zone terminal equipment.

While simpler “Turn it Off” measures that are typically applied during ReCx/RCx provide a significant amount of savings, savings can be more than doubled using the other three measurement categories. However, this requires an understanding of system optimization and Building Re-tuning™. Additional details on documented energy savings can be found in PNNL’s meta-analysis report (Katipamula 2015).

The goal of Re-tuning is to optimize system operation. However, it is important to note that Re-tuning may increase energy use. For instance, manual changes might have been made to close an outdoor air damper to mitigate humidity problems in a building. In cases like this, Re-tuning will correct the system operation to bring in the appropriate amount of outdoor air, which may cause energy consumption to increase.

Solutions and Actions

Re-tuning: When and Where/Qualification Questions

Identification of Re-tuning opportunities involves the following primary activities:

- Collection of basic building information

- Trend-data collection and analysis

- Building walk down

- Identification and implementation of Re-tuning actions

- Report of findings, recommended actions, and recommendations implemented

- Savings analysis

- Continued use of Re-tuning in O&M

As illustrated in Figures 1 and 2, the process of Re-tuning becomes the most beneficial when the existing BAS, systems, and equipment allow for measures based on all four principles of Building Re-tuning™. Many of the reset strategies categorized in “turn it down” and “mitigate simultaneous heating and cooling” require the variable volume operation of systems as well as modern BASs with the ability to reset setpoints depending on demand. Also, the energy savings opportunities are greater in systems that have a larger number of zones in which load variance is significant throughout the day and the season. Below is a summary of the typical building and system conditions that likely benefit the most from Re-tuning efforts:

- Large buildings with a minimum square footage of 100,000 ft2

- Buildings with higher energy use intensity (EUI) compared to baseline or against similar (benchmarked) buildings—higher energy savings potential

- Buildings with higher utility cost and therefore higher energy cost savings potential

- BASs in good working condition that do not require full ReCx/RCx

- Digital controllers, actuators, and thermostats

- Updated within the last five to eight years

- Controls major air handling units

- Controls central plant equipment, including chillers and boilers.

- Availability of trend data expands data analysis capabilities.

- Buildings with variable volume airside and waterside systems:

- Multi-zone single-duct air handling units with supply fan variable frequency drives.

- Buildings with dedicated outdoor air systems provides additional savings opportunities.

- Variable speed operated pumps.

The sources of data and information that are essential to Re-tuning activities are:

- Whole building utility interval meter data (electricity, natural gas, steam, and/or chilled water)

- ENERGY STAR building performance rating or building EUI

- Equipment design documents including plans, schedules, and operation control sequence

- Trend data

- History of occupant complaints

Re-tuning as a Tool to Address Low-Cost/No-Cost O&M Needs

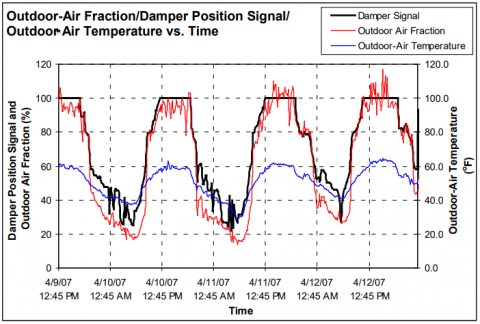

The data collected and analyzed is used to seek energy efficiency opportunities and address the O&M needs associated with system and/or component deficiencies. While ReCx/RCx involves component-by-component observation, the process of Re-tuning typically utilizes available trend data to understand equipment operation. For instance, as illustrated in Figure 3, the temperature data around the mixed air damper at the air handler can be used to calculate the amount of fresh air (outdoor air fraction) being brought into the system. This value can be plotted with the damper signal or command. If the temperature data do not correspond to the damper signal, the damper’s function may be compromised, indicating linkage or actuator problems. Likewise, similar observations can be performed around heating and cooling valves, etc., to verify the system’s response to control signals.

Conclusion and Next Steps

The Re-tuning process optimizes the energy-efficient operation of facilities and systems and aims to provide the “right” amount of heating, cooling, and ventilation throughout the year without compromising the occupant’s comfort or zonal needs. The Re-tuning process can be used to verify that equipment operation meets the design intent and current operational needs and to identify the area of O&M needs related to control components such as valves and actuators. If O&M needs are minor, the process satisfies the requirement set by EISA 432.

The first step of Re-tuning is to go through the list of assets and identify the buildings with the greatest opportunities for operational improvements and energy savings through Re-tuning. The list of building conditions and items provided in the previous sections may be used to filter and pre-qualify the buildings for possible Re-tuning work. Training is available through the Federal Energy Management Program (FEMP) and its Re-tuning Challenge, which provides additional details on data analysis and savings potentials.

Additional Resources

Building Re-tuning™ Interactive Web-Based Training

PNNL has developed an online Building Re-tuning™ course that teaches how to assess buildings’ energy needs, identify opportunities for improvement, and implement low-cost changes to reduce overall energy consumption. The hands-on course utilizes the best elements of classroom and field training to deliver engaging, virtual learning activities. The course can be accessed at https://retuningtraining.labworks.org/training/lms/.

FEMP Re-tuning Challenge

FEMP launched the Re-tuning Challenge to provide agencies with a no-cost opportunity to receive training and support for a building in their portfolios. The Re-tuning Challenge includes a site visit by the FEMP Re-tuning team, on-site training for staff, completed Re-tuning of one building, results monitoring, and ongoing (remote) support. More information about the Re-tuning Challenge can be found at https://www.energy.gov/eere/femp/re-tuning-challenge.

Guideline for Energy Independence and Security Act

Section 432 of the Energy Independence and Security Act of 2007 (EISA) prescribes a framework for facility energy project management and benchmarking. There are several approaches for completing comprehensive energy and water evaluations, and the information can be accessed at https://www.energy.gov/sites/prod/files/2013/10/f3/eisa_s432_guidelines.pdf.

Definitions

- Building Automation System (BAS). A system of digital controllers, communication architecture, and user interface that monitors and controls a building’s mechanical and electrical equipment such as heating, ventilation, and air conditioning (HVAC), lighting, fire protection, vertical transport systems, and irrigation systems. The system can be used to optimize facility operation and reduce energy consumption. Also known as building control system or energy management system.

- Commissioning. The term commissioning, with respect to a facility, is defined in 42 U.S.C. 8253(f)(1)(A) as:

- “ a systematic process

- - “(i) of ensuring, using appropriate verification and documentation, during the period beginning on the initial day of the design phase of the facility and ending not earlier than 1 year after the date of completion of construction of the facility, that all facility systems perform interactively in accordance with

- (I) the design documentation and intent of the facility;

- (II) the operational needs of the owner of the facility, including preparation of operation personnel; and

- (ii) the primary goal of which is to ensure fully functional systems that can be properly operated and maintained during the useful life of the facility.”

- - “(i) of ensuring, using appropriate verification and documentation, during the period beginning on the initial day of the design phase of the facility and ending not earlier than 1 year after the date of completion of construction of the facility, that all facility systems perform interactively in accordance with

- “ a systematic process

- Energy Use Intensity (EUI). A metric of annual energy use per floor area that is commonly used in benchmarking energy use data.

- Recommissioning (ReCx). The term recommissioning means a process:

- “(i) of commissioning a facility or system beyond the project development and warranty phases of the facility or system,

- – “(ii) the primary goal of which is to ensure optimum performance of a facility, in accordance with design or current operating needs, over the useful life of the facility, while meeting building occupancy requirements.” (42 U.S.C. 8253(f)(1)(F))

- “(i) of commissioning a facility or system beyond the project development and warranty phases of the facility or system,

- Retrocommissioning (RCx). The term retrocommissioning means a process of commissioning a facility or system that was not commissioned at the time of construction of the facility or system. (42 U.S.C. 8253(f)(1)(G))

References

42 USC 8253 et seq. 2007. Energy Independence and Security Act. Public Law 110-140, as amended. https://www.govinfo.gov/content/pkg/PLAW-110publ140/pdf/PLAW-110publ140.pdf

DOE – U.S. Department of Energy. 2008. Facility Energy Management Guidelines and Criteria for Energy and Water Evaluations in Covered Facilities (42 U.S.C. 8253 Subsection (f), Use of Energy and Water Efficiency Measures in Federal Buildings). U.S. Department of Energy, Washington, DC. https://www.energy.gov/sites/prod/files/2013/10/f3/eisa_s432_guidelines.pdf FEMP –

Federal Energy Management Program. (n.d.) Re-tuning in Federal Buildings: Re-tuning Challenge. https://www.energy.gov/eere/femp/re-tuning-challenge.

Katipamula, S. 2015. Improving Commercial Building Operations thru Building Re-tuning: Meta-Analysis. PNNL Presentation PNNL-SA-110686, Pacific Northwest National Laboratory, Richland, Washington. https://buildingretuning.pnnl.gov/documents/pnnl_sa_110686.pdf

PNNL – Pacific Northwest National Laboratory. 2018. Building Re-tuning™. https://buildingretuning.pnnl.gov/ (last updated November 2018).

———. (n.d.). Building Re-tuning™ Training. https://retuningtraining.labworks.org/training/lms/

———. 2012. Large Commercial Buildings: Re-tuning for Efficiency. Air Handling Units: Pre-Re-tuning and Trending and Re-tuning https://buildingretuning.pnnl.gov/documents/chapters/ch5_air_handling.pdf

Actions and activities recommended in this Best Practice should only be attempted by trained and certified personnel. If such personnel are not available, the actions recommended here should not be initiated.

Published May 2021