Bioenergy

Technologies

Bioenergy

Technologies

Turning biomass into

fuels for the future

Turning biomass into

fuels for the future

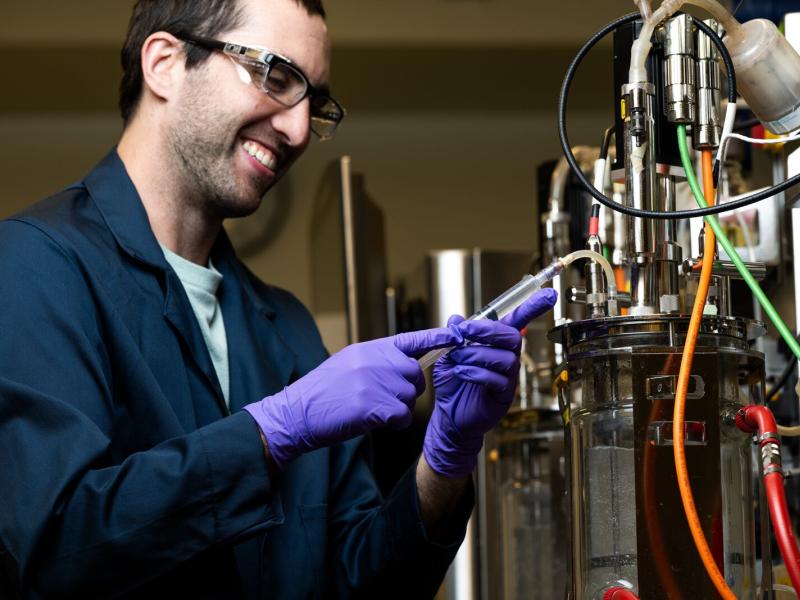

Researcher Jim Collett is using Process Analytical Technology (PAT) to identify optimal conditions for growing lipid-rich yeast within one of the bioreactors at the Bioproducts, Sciences, and Engineering Laboratory. Such yeast are promising feedstocks for the production of renewable diesel, jet fuel, and other bio-based chemicals.

Andrea Starr | Pacific Northwest National Laboratory

At PNNL, researchers are making high-quality drop-in fuels and valuable chemical products using plentiful domestic resources (like wood and algae) and waste products (like food and agricultural wastes, manure, and sewage sludge). These biofuels and bioproducts offer cost-effective, domestically sourced alternatives, offering pathways to grow the economy and strengthen supply chains.

PNNL has unique capabilities and research expertise in biofuels and bioproducts, including in high-impact areas like advanced biotechnology, catalysis, and thermal processing. For example, at PNNL's Sequim campus—the only marine sciences facility in the DOE complex—researchers are enabling the use of algae and seaweed as feedstocks for producing fuels, products, and critical minerals. At PNNL’s Richland campus, researchers are at the forefront of hydrothermal liquefaction—an emerging technology that uses high pressures and temperatures to mimic the geological conditions the Earth uses to create crude oil, achieving in minutes what typically takes millions of years.

These kinds of bioenergy innovations create high-value fuels and products using waste and other low-cost materials—and it’s all done right here in the U.S.A.