Friction Stir

Friction Stir

A suite of methods for

combining and

augmenting materials

A suite of methods for

combining and

augmenting materials

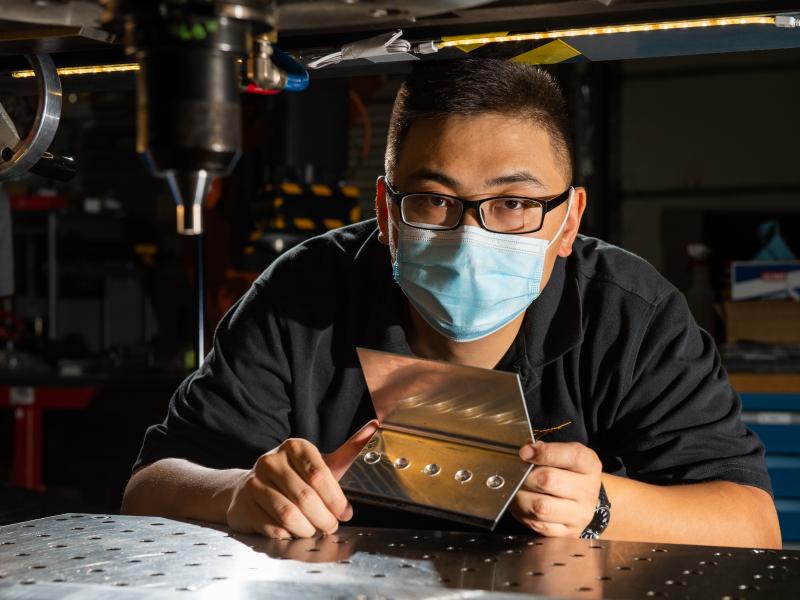

A researcher with PNNL's friction stir welding machine.

(Photo by Andrea Starr | Pacific Northwest National Laboratory)

Friction stir techniques involve the use of a spinning tool to generate intense levels of deformation and heat, transforming or joining the target material(s). For instance, the tool could be traversed across metal sheets along a joint line, causing the metals to physically mix together to be precisely joined without the use of rivets and fasteners (friction stir welding). Alternatively, the tool could be translated across the surface of a material, creating a modified region with superior properties (friction stir processing). Friction stir techniques can join dissimilar materials that cannot be joined by other methods, enabling the production of next-generation products—and they also require less energy than conventional methods, reducing costs.

Researchers in the Smart Advanced Manufacturing (SAM) program at Pacific Northwest National Laboratory (PNNL) have improved various stir processing methods by advancing tool designs or inventing new ways to “stir” the materials involved to provide improved manufacturing processes or improved products. Furthermore, advanced control systems have enabled greater manufacturing automation by integrating friction stir techniques with robotic systems.

Friction stir welding

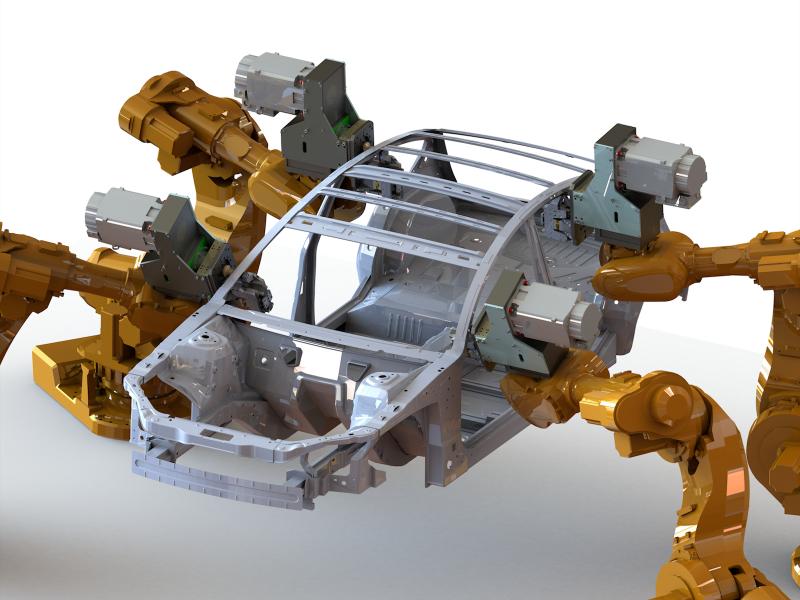

Friction stir welding is a joining technique in which a rotating tool plunges into the material, creating “friction” between the tool and the metal that results in localized heating and softening as the tool moves along a path across the material. PNNL has transformed friction stir welding to make it faster and allow it to join metal sheets and castings of various thicknesses and geometries. Among other things, this means friction stir welding can create all-aluminum parts, or parts made up of a combination of different metals and polymers, without rivets and fasteners that would increase the cost and weight. A commercial production company built around PNNL’s advanced processes has produced material for full-sized automotive body-in-white substructures.

Friction stir processing

Friction stir processing is a variation on friction stir welding. A spinning, non-consumable tool is translated along the surface of a material to form a modified region with improved properties compared with the base material. The approach is used to selectively modify alloys such that the resulting components and assemblies exhibit locally enhanced properties and deliver high materials performance in the locations most needed. This allows for significant improvements in the manufacturability, structural efficiency, and weight savings of next-generation vehicles. Furthermore, friction stir processing enables the right properties, in the right locations, and provides the opportunity to reduce the number of metal alloys required for new vehicle manufacture—reducing the challenges that automakers face today in managing supply chains.

Friction stir dovetailing

Friction stir dovetailing allows thick cross-sections of steel, aluminum, and other materials to be joined—something not possible with conventional welding because of material thickness and disparate melting points.

Friction stir dovetailing provides solutions for designers and engineers of large structures to optimize for functionality and weight based on targeted use requirements. It’s valuable for manufacturing military combat vehicles, for instance, to lower fuel expenses and increase agility, strength, and operational effectiveness. Applying the same concept as a woodworker’s dovetail joint, researchers form metallic interlocks by using a specially designed tool and precise control of pressure and temperature to deform aluminum into a dovetail groove in the steel.

Simultaneously, the tool rubs along the bottom of the dovetail, forming ultra-thin layers that chemically bond, acting like glue. The resulting joints, when incorporated in hybrid material designs, are lighter and stronger than all-steel components, thereby increasing the efficiency and maneuverability of military vehicles.

Friction stir scribe

PNNL's award-winning friction stir scribe process makes it possible to join materials with drastically different melting points with no need for additional adhesives, bolts, or rivets. Using this design and process technique, manufacturers can now incorporate new and different materials into a variety of lightweight or functionally optimized parts without sacrificing strength or durability.

Joining dissimilar materials—steel and aluminum—through this specialized, award-winning friction stir welding process can produce lighter-weight components for multi-material vehicles, providing greater fuel efficiency.

Friction stir interlocking of dissimilar non-metal materials

Two unique friction stir techniques have been developed at PNNL to join lightweight materials to composites, plastics, ceramics, or other non-metallic materials in a single pass. This technology can be used to reduce the weight of automotive components and components of any application—for example, bridges—where robust joints between magnesium or aluminum and non-metals are required.

The first approach involves embedding metal inserts within the non-metal and subsequently friction stir welding the metal sheet or plate directly to the metal insert. The second involves inserting metal pins through the non-metal, much like a rivet, and then friction stir welding the metal sheet or plate directly to the metal insert to form a mechanical fastener. Friction stir interlocking also reduces the galvanic and pitting corrosion that can occur between metal fasteners and carbon fibers within composite materials.

Robust advanced control systems for friction stir welding

PNNL researchers have developed robust methods and algorithms to control processing conditions, such as temperature, with unprecedented thermal control accuracy across the length of a friction stir weld. Important weld properties, such as fracture toughness and corrosion resistance, vary with weld temperature. This temperature can be adjusted during the weld for quality and the creation of specified properties. Precise control of temperature has enabled PNNL to achieve unprecedentedly low-temperature welds and superior properties in steels. This increases efficiency and requires less processing. Temperature control can drive higher speeds and accommodate lower part tolerances, increasing the value proposition of friction stir processing for high-volume manufacturers.