Vehicle

Technologies

Vehicle

Technologies

Accelerating the future

of American-made vehicles

Accelerating the future

of American-made vehicles

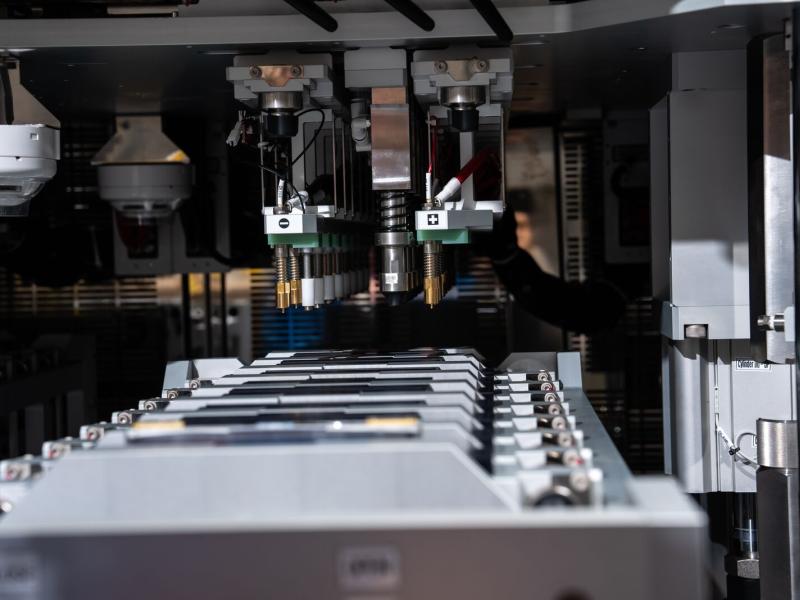

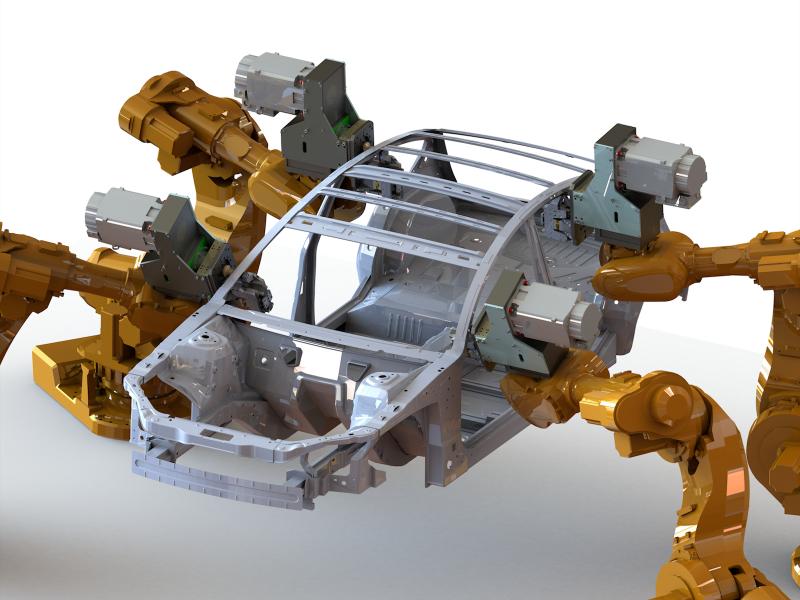

At Pacific Northwest National Laboratory, vehicle research is about more than how vehicles are powered—it’s also about how they’re made and used. The Lab’s vehicle technology research portfolio advances all types of vehicles—on-road, rail, maritime, aviation, and off-road—through a range of innovations, from helping manufacturers produce high-performance vehicle components using low-cost domestic materials, to optimizing the movement of goods and people around the nation, to effectively and reliably integrating vehicles with electricity and energy systems.

PNNL leverages decades of experience and strong expertise in chemical and materials science, systems engineering, computing, and data science to advance a range of low-cost, high-quality transportation solutions. That means superior, lightweight car parts made using advanced manufacturing techniques; lower-cost, longer-lasting batteries; optimized traffic enabled by advanced AI and analytics; and smart integration between vehicle technologies, the electric grid, and other national infrastructure. And it’s not just research for its own sake: PNNL has a proven track record of translating transportation innovations into real-world commercial products.

PNNL research and innovations are enabling a new future for vehicles: smarter, more reliable, more affordable, connected to energy infrastructure, and best of all, leveraging technology made in the United States.