Materials in

Extreme

Environments

Materials in

Extreme

Environments

Scientists profile intact biological samples by applying a technique known as “pressurized magic angle spinning technology” to nuclear magnetic resonance spectroscopy for analysis of complex samples under conditions that mimic real-world environments, such as those found in the deep ocean or underground. This technology has been used to study carbon sequestration, recreate conditions deep underground and track the complex chemical reactions in biofuels. A team from EMSL, the Environmental Molecular Sciences Laboratory, and Pacific Northwest National Laboratory won an R&D 100 award in 2015 for the pressurized magic angle spinning technology.

Andrea Starr | Pacific Northwest National Laboratory

When placed in extreme environments (e.g., in a highly corrosive atmosphere or under intense radiation), materials can behave in unexpected and unpredictable ways. Understanding the forces that affect material behavior in extreme environments is critical to ensuring the safety and reliability of industrial processes and accelerating the processing of radioactive wastes at Department of Energy sites.

With more than 50 years studying material effects in high pressure, high temperature, corrosive, and radioactive spaces, PNNL has established the scientific expertise necessary to advance understanding of material behavior in these environments. We have developed and employed specialized synthesis and characterization tools available in few other research settings. Studies use specialized labs for research with microgram-to-kilogram quantities of fissionable materials and megacurie activities of other radionuclides, housed in the Radiochemical Processing Laboratory, a Hazard Category II non-reactor nuclear research facility. Combined with radiation characterization capabilities in the Materials Science and Technology Building and other facilities, researchers at PNNL are able to develop an understanding of the structures of materials exposed to radioactivity.

Additional advanced materials characterization instrumentation, including atom probe tomographs, transmission electron microscopes, and nuclear magnetic spectrometers located in the Environmental Molecular Sciences Laboratory, a national user facility, and the new Energy Sciences Center contribute to our ability to understand the fundamental behavior of materials.

Radioactive waste is often extremely corrosive and constantly evolving. Understanding the long-term behavior of this complex chemical milieu is necessary to assure responsible stewardship. Toward that goal, PNNL leads a multidisciplinary, multi-institutional team examining the unique chemistry of this environment. The Ion Dynamics in Radioactive Environments and Materials (IDREAM) Energy Frontier Research Center combines theory with experimental testing aiming to predict material behavior in radioactive environments.

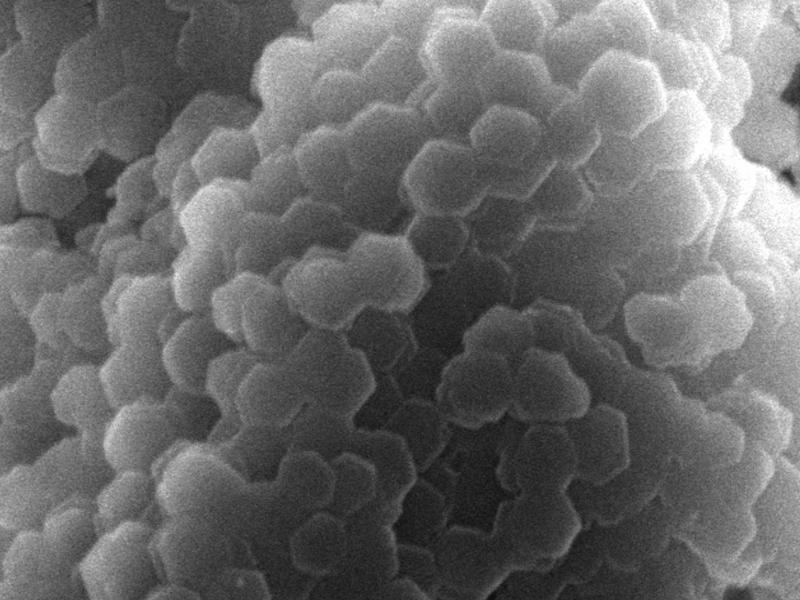

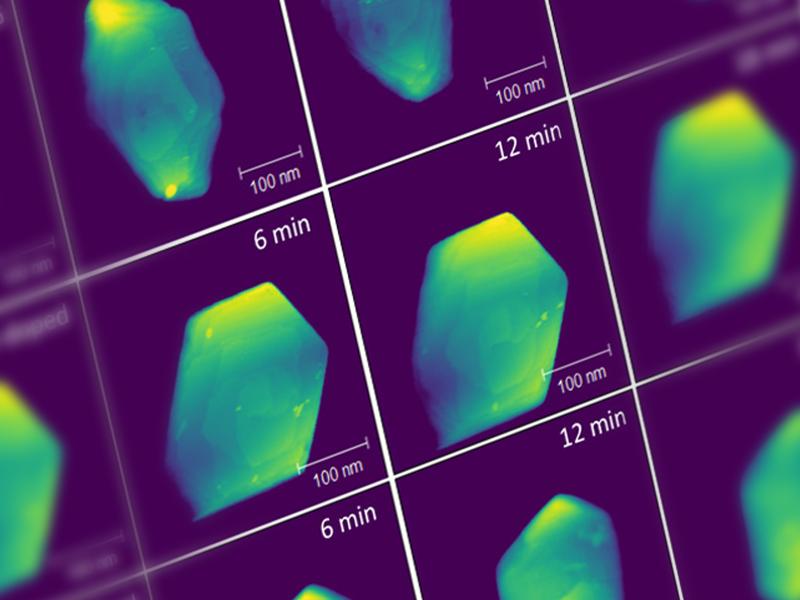

For example, during radioactive waste treatment, the process of dissolving waste is often quite slow. To understand why, researchers used high-field magic angle spinning nuclear magnetic resonance spectroscopy to get a close-up view of how gibbsite, a type of aluminum crystal, forms and dissolves. They discovered that the process involves a complicated (and slow!) change in structure that had not been fully understood. The team captured real-time system dynamics as a function of experimental conditions, revealing previously unknown details. Understanding how aluminum coordination changes in extreme environments may lead to efficiencies in aluminum production and accelerate radioactive waste processing.

Other related research is focused on revealing how harsh environments, including corrosion and irradiation, affect surface diffusion and reactivity, materials synthesis pathways, materials functions, and microstructure.

Our materials science expertise also is used in energy, infrastructure, and national security applications with techniques such as nondestructive examination (NDE), which evaluates the integrity of materials, structures, and components. NDE provides insights into material systems throughout their lifecycle—during manufacturing, post-fabrication, and in situ operation—resulting in a comprehensive understanding of material conditions and degradation. This knowledge can be used to extend the useful life of components and to guide mitigation, repair, or replacement decisions. For example, a long-standing NDE research partnership between PNNL and the Nuclear Regulatory Commission has captured key technical bases and recommendations in more than 250 Nuclear Regulatory Report/Contractor Reports and Technical Letter Reports. This body of work represents the evolution of NDE to address emerging issues in the nuclear energy industry, impacting and advising the safe, sustainable operation of the nuclear power plants that provide nearly 20 percent of the nation's electricity.

PNNL's NDE experts are equipped with front-line instrumentation, probes, artificial intelligence/machine learning models, and sensors. Our extensive inventory includes materials and components from vintage nuclear power plants, complemented by the latest in multiphysics-based modeling and simulation capabilities.