Nuclear Material Science

Nuclear Material Science

Strategic nuclear material

production and processing

Pacific Northwest National Laboratory is a leader in the science and technology of strategic material production and processing, including tritium, uranium, and plutonium.

(Image by Sergey Nivens | Shutterstock.com)

Pacific Northwest National Laboratory (PNNL) is a leader in the science and technology of strategic material production and processing, including tritium, uranium, and plutonium. Our cutting-edge nuclear material science capabilities are rooted in the support for Hanford’s defense mission during the Manhattan Project and the Cold War. The resources, facilities, and collaborations across disciplines at PNNL, the national laboratory system, academia, and industry enable us to develop and use a deep understanding of nuclear materials to drive mission impact in stockpile stewardship, nonproliferation, and nuclear energy.

PNNL continues to invest in the expansion and enhancement of our capabilities in nuclear-material processing. For example, we are working to accelerate modeling-based prediction of material microstructure through targeted application of high-fidelity models for fundamental phenomena; lower-resolution models to characterize trends across broad ranges of the process parameter space; and science-informed machine learning to accelerate the discovery and interpretation of relationships across length and time scales. We are also developing and applying advanced noninvasive diagnostic methods that can provide real-time validation of product characteristics to reduce the need for sampling-based offline characterization and to inform data-driven process control. PNNL has numerous activities in the development and use of physics-informed data analytics methods tailored to material processing, including the interpretation of complex patterns in the process–structure–property relationships that govern material performance.

Stay connected and subscribe to Nuclear@PNNL. Each e-newsletter issue highlights the expertise of our researchers, their contributions to the nuclear mission space, and our research facilities where discoveries and advancements are made.

Nuclear material science is the foundation of reliable tritium production

PNNL is the design authority for the tritium-producing burnable absorber rods (TPBARs) used to produce tritium for the nuclear weapons stockpile. PNNL is the recognized leader in the science and engineering of tritium production, and all of its research in this area is focused on improving the science, understanding, performance, and design of the TPBARs.

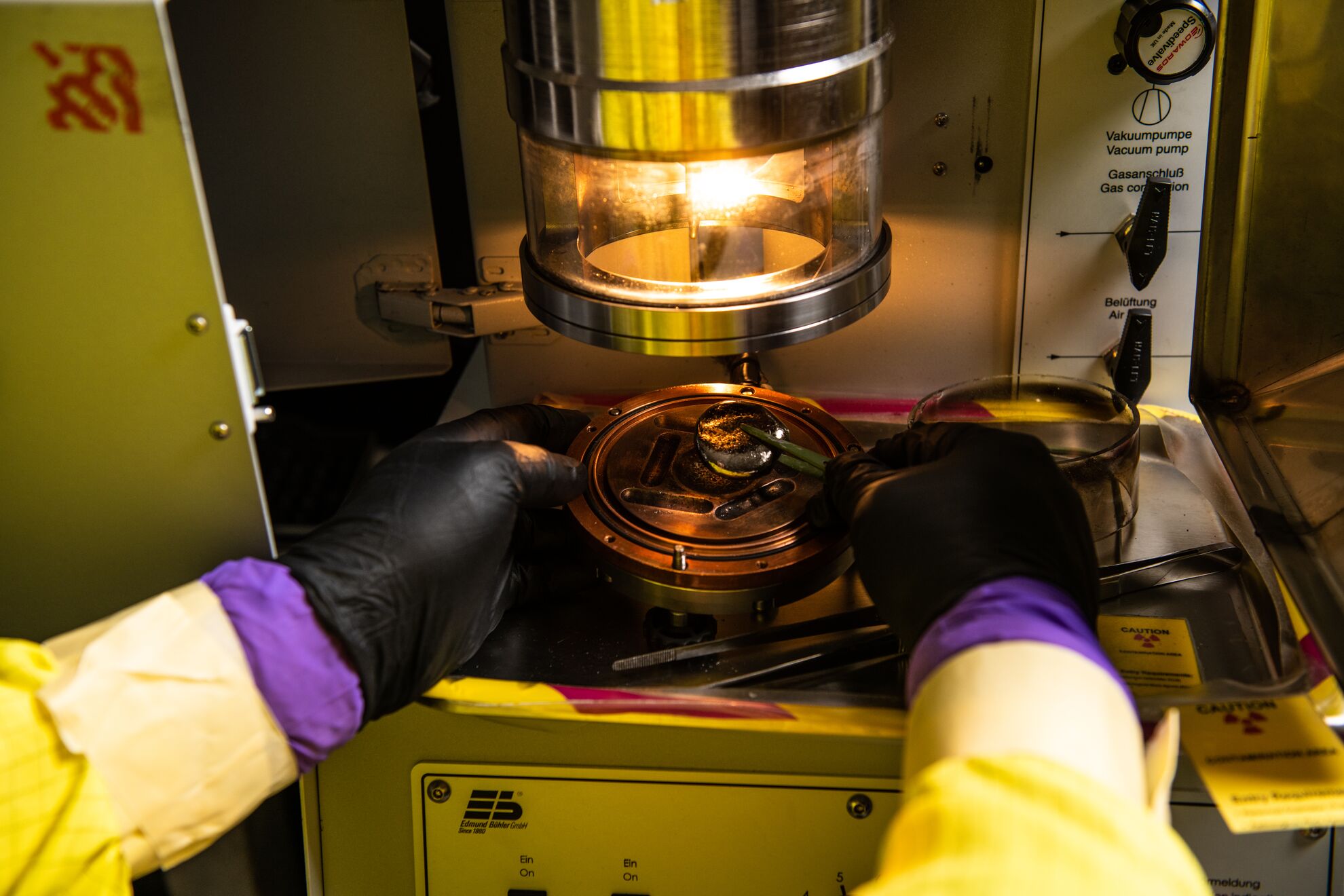

Our experts examine TPBARs from most production cycles after being irradiated. A wide variety of characterization and testing tools and techniques at PNNL’s Radiochemical Processing Laboratory and Material Science and Technology Laboratory evaluate the performance of production TPBARs as well as new TPBAR materials, components, and configurations. These tests and techniques include gas analysis, hydrogen and helium isotope assays, analytical chemistry, microscopy, mass spectrometry, surface science, and reactor dosimetry. All data are used to drive improvements in modeling, specifications, and ultimately, TPBAR performance.

Test beds help maintain nuclear material science competency

At the end of the Cold War, many of the capabilities and workforce associated with actinide processing declined or disappeared altogether. As the U.S. weapons enterprise works to reestablish and modernize the nation’s large-scale production capabilities, PNNL has done the same at the research scale, establishing uranium and plutonium test beds in the Radiochemical Processing Laboratory, which are flexible and adaptable to support a wide range of projects. The end-to-end plutonium processing test bed enables research, development, and testing from spent fuel dissolution through aqueous purification and metal production. The end-to-end uranium processing test bed enables research, from scrap recovery and purification to casting to metal machining.

When Hanford had an active defense mission, PNNL developed capabilities such as processing uranium for fuel to be loaded into the production reactors and recovering and processing plutonium from the irradiated fuel. Today, our experts continue to apply these distinctive scientific capabilities in actinide processing to science-based production modernization for the nuclear weapons enterprise. These cutting-edge capabilities also help us anticipate how special nuclear material production and processing might evolve in the future so that we can detect, verify, or counter such technologies when they violate international treaties for nuclear nonproliferation.

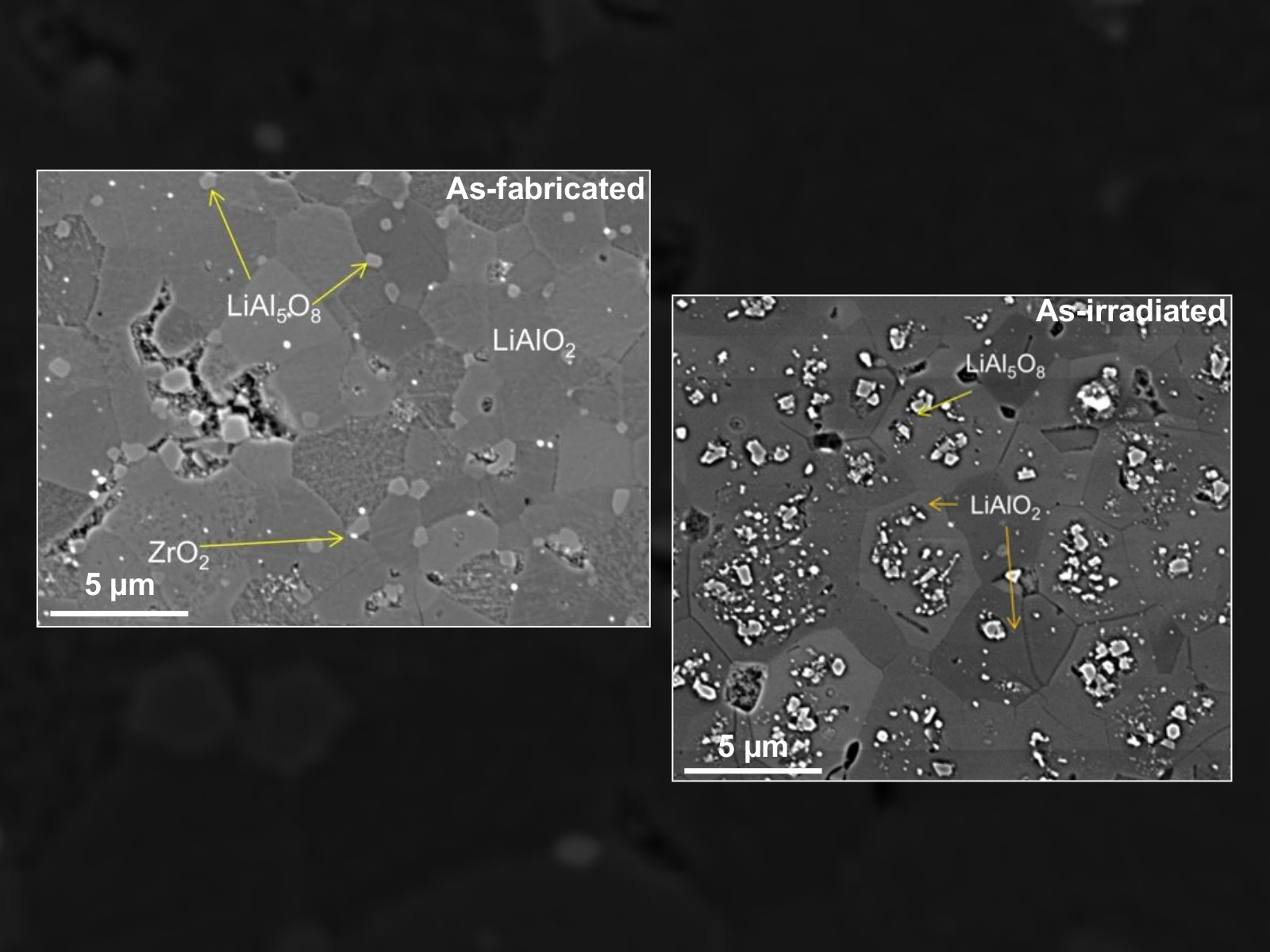

Multiscale characterization informs process–structure–performance relationships of nuclear materials

A material’s microstructure dictates its performance for its intended use. Therefore, a deep understanding of how a manufacturing process affects material microstructure and how that microstructure evolves during material use (e.g., irradiation in a nuclear reactor or corrosion in extreme environmental conditions) is essential. Staff at PNNL use state-of-the-art characterization tools to evaluate and characterize material microstructure and performance across a wide range of length scales, from bulk mechanical properties to atomic-level composition and structure. PNNL’s ability to perform such analyses on radioactive samples allows us to support a wide range of missions related to the production and processing of these strategic materials.

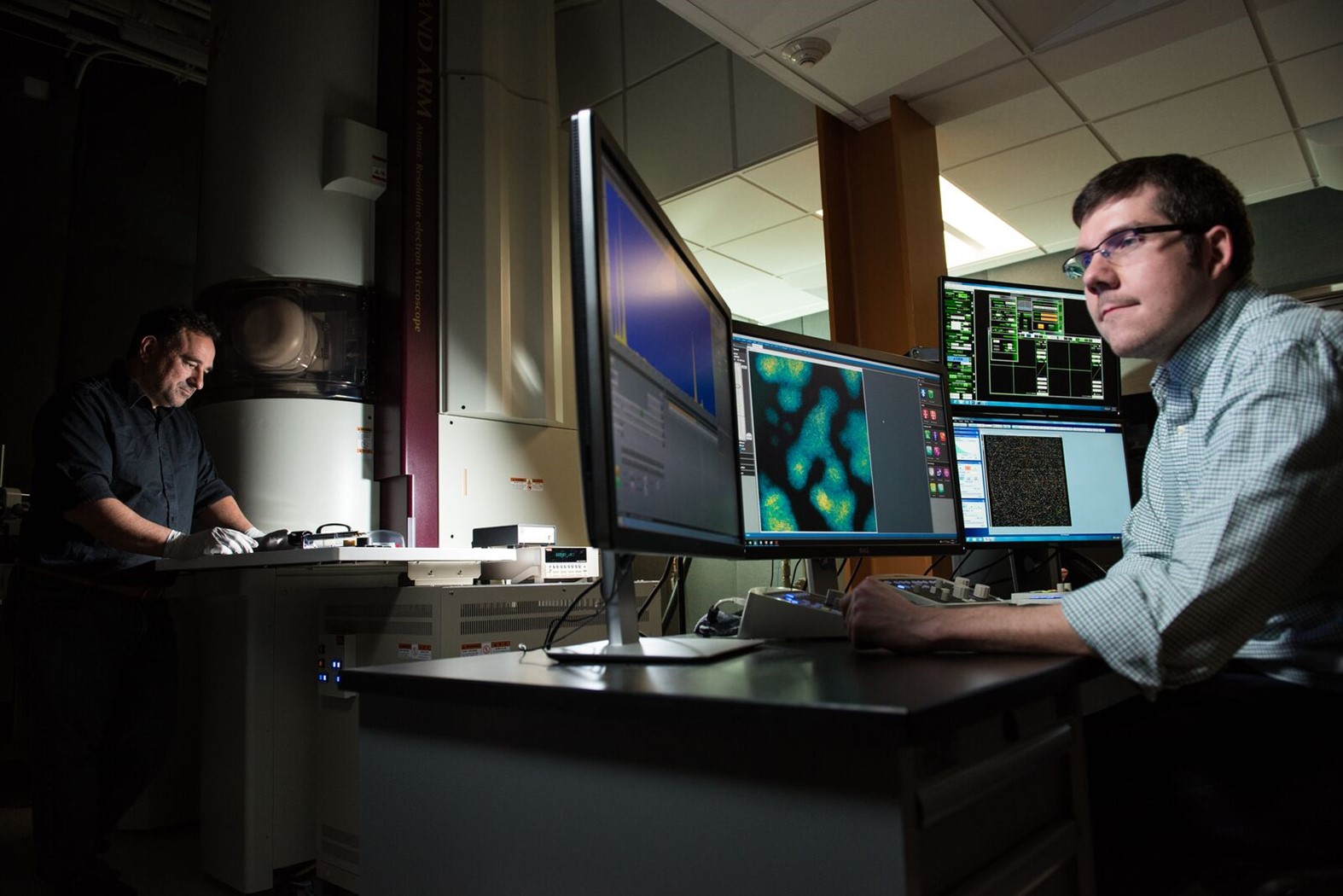

Exquisitely sensitive analytical instruments characterize nuclear materials

Within the Radiochemical Processing Laboratory, the Quiet Suite is a set of laboratories that is isolated from various sources of “noise” in the building. This suite houses highly sensitive analytical instruments, including a dual beam focused ion beam-scanning electron microscope, an atomic force microscope, and an aberration-corrected transmission electron microscope. These sensitive instruments require a space that is isolated from vibrational and electromagnetic noise and has a consistent temperature to perform the deep characterization of nuclear materials.

A new addition to our radioactive materials characterization capabilities in the Radiochemical Processing Laboratory is an atom probe tomography system that is capable of imaging, on an atom-by-atom basis, the elemental and isotopic composition of a sample. It is an invaluable tool for studying interfaces that determine the behavior of tiny microstructural features and validating atomic-scale predictive modeling.

Nuclear materials science informs work on alternative fuels for research reactors

An important part of the United States government’s nonproliferation efforts is reducing the risk of hostile states and non-state actors acquiring nuclear material for an improvised nuclear device. A first step in minimizing the use of weapons-usable nuclear material is to eliminate the need for and availability of the material. Through its nuclear material research, PNNL is part of the effort to reduce this risk by developing and qualifying fuels of low-enriched uranium to convert research reactors that cannot convert with existing low-enriched uranium fuels.

Current research reactor fuels have high enrichment and low density. Converting to low-enriched uranium fuels with high densities presents challenges in design, manufacturing, and performance. PNNL’s role is developing the fuel manufacturing processes and then transferring the technology to the commercial supply industry. PNNL’s experts are employing integrated computational materials engineering to understand material microstructure and the thermomechanical processes of manufacturing. Modeling at multiple scales (from atomistic to finite element) furthers the understanding, and fuel performance modeling (conducted with national laboratory partners) informs decisions on the fuel design and cost-effectiveness of the manufacturing.