Vehicle Electrification

Vehicle Electrification

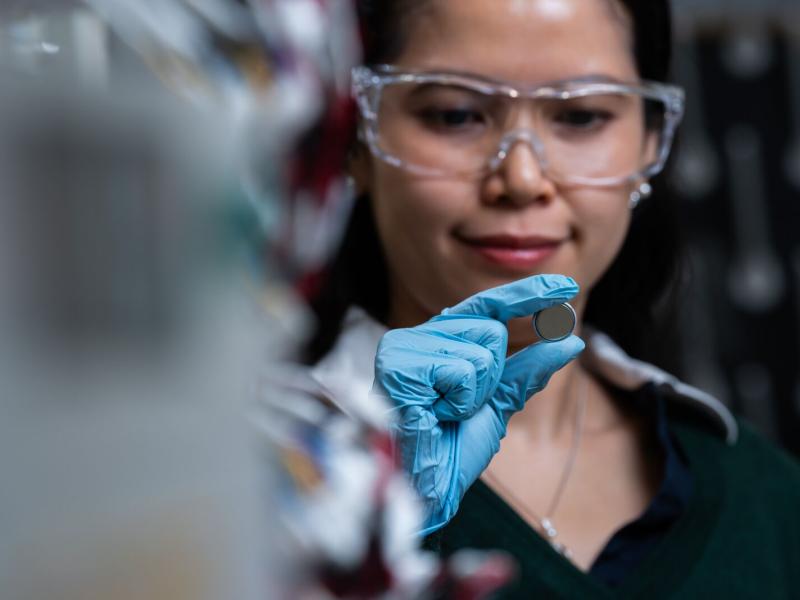

Leading battery research that

powers today’s electric vehicles

Leading battery research that

powers today’s electric vehicles

PNNL and partners are working closely with the U.S. Department of Energy’s (DOE’s) Vehicle Technologies Office (VTO) to solve challenges surrounding vehicle electrification.

Challenges of vehicle electrification

Battery-powered vehicles are steadily gaining popularity with consumers. However, there are challenges associated with developing batteries for these vehicles, such as the need to improve affordability and to make them longer lasting and more durable, and the need to reduce the amount of critical minerals and materials needed for batteries and other vehicle components.

For example, today’s state-of-the-art electric vehicles are powered by lithium-ion batteries, which typically last about 1,000 cycles—meaning they can be fully charged and discharged 1,000 times before they sufficiently lose performance and require replacement. A vast improvement in power is the emerging lithium-metal battery, which holds almost twice the energy of lithium-ion batteries. Lithium-metal batteries are lighter weight as well, offering the prospect of lighter cars that go much farther on a single charge. But, similar to other battery types, lithium-metal batteries have been plagued by less-than-desirable lifespans, lasting only a fraction of the time of today’s batteries.

In addition to challenges posed by batteries, concerns have arisen about whether utilities, grid planners, and cities are prepared for the impact of fast-charging vehicles on electricity infrastructure—both in large metropolitan areas and smaller communities. Rolling brownouts or even complete blackouts in most regions could become a significant problem in the relatively near future as demand increases for charging electric vehicles.

Finally—in the materials science arena—the automotive industry needs improved functionality in materials, such as higher conductivity for increased motor efficiency, electronics, and lighter-weight components that are expected to power future electric vehicles.

Breakthroughs in vehicle electrification

To help VTO address these challenges, PNNL scientists and engineers are at the forefront of electrochemical energy storage and chemical energy storage. PNNL is currently leading the Battery500 Consortium for DOE to address the fundamental challenges that enable next-generation lithium-metal batteries for electric vehicles that have potentially double the specific energy of current batteries so the vehicles can drive longer distances, last longer, and become more affordable to the consumer.

At the behest of VTO, PNNL scientists, along with industry, academic, and other national laboratory partners, are pushing the frontiers of advanced electrode and electrolyte materials and are developing strategies to integrate materials science, electrochemistry, and cell engineering to enable lithium-metal battery technology. In the Battery500 Consortium, all new ideas and materials are validated in realistic high-energy test batteries to make sure our findings are relevant to industry applications. The prototype batteries from the consortium have already achieved 350 Wh/kg and 400 Wh/kg energy outputs and world-record cycling stabilities.

As a huge enabler toward electrifying our nation’s transportation sector, PNNL is taking a stance of “infrastructure matters.” This quickly growing research area is focusing on smart charging management through the development of advanced multi-modal analytics and predictive tools to help decision-makers—both on the vehicle and grid sides—identify technology and infrastructure needs for better integration of electric vehicles. Our researchers are taking the helm on first-ever studies that evaluate several factors, including electric trucks for delivery and long-haul, as well as smart vehicle charging strategies. Studies are providing utilities and grid planners with the information to understand the impacts to the grid and planning so that our national transportation and grid infrastructures can be optimized.

To complement the electrification efforts, teams of materials researchers at PNNL are studying and developing lightweight materials that will bring forth more fuel-efficient vehicles. Additionally, they are using these materials science and manufacturing skills to improve the functionally of metal alloys—such as copper and aluminum—that result in much higher conductivity for improving the performance of electric vehicle components while reducing aspects like motor volume and weight.