Lightweight Materials

Lightweight Materials

Leading the way in materials

manufacturing for lightweight,

efficient vehicles

Leading the way in materials

manufacturing for lightweight,

efficient vehicles

Every time gas prices rise, American consumers feel pain at the pump. To wring more mileage out of every precious gallon, auto manufacturers aim to produce vehicles that are lighter than yesteryear’s counterparts. Even a 10 percent reduction in vehicle weight can translate to an additional six to eight percent improvement in fuel economy.

Materials such as magnesium and aluminum alloys, carbon fiber, and polymer composites, can reduce the weight of a vehicle up to 50 percent. That difference can mean a lot of extra miles between gas pump fill-ups.

Recognizing the potential impact that lightweight vehicles can have on fuel economy, the U.S. Department of Energy (DOE) Vehicles Technologies Office is turning to scientists and engineers at PNNL to investigate and improve these materials. Manufacturers can then incorporate them into vehicle components like chassis and frames on their production lines.

Not heavy metals: magnesium, aluminum, and composites

PNNL leads the way in the world of materials manufacturing through its Smart Advanced Manufacturing (SAM) program. SAM leverages several solid phase processing techniques, which apply high strain to materials during fabrication to produce high-performance alloys, semi-finished products, and engineered assemblies without the requirement to melt the constitutive materials. The process holds the potential to decrease the energy intensity of manufacturing and deliver higher-performing components, all at a lower cost.

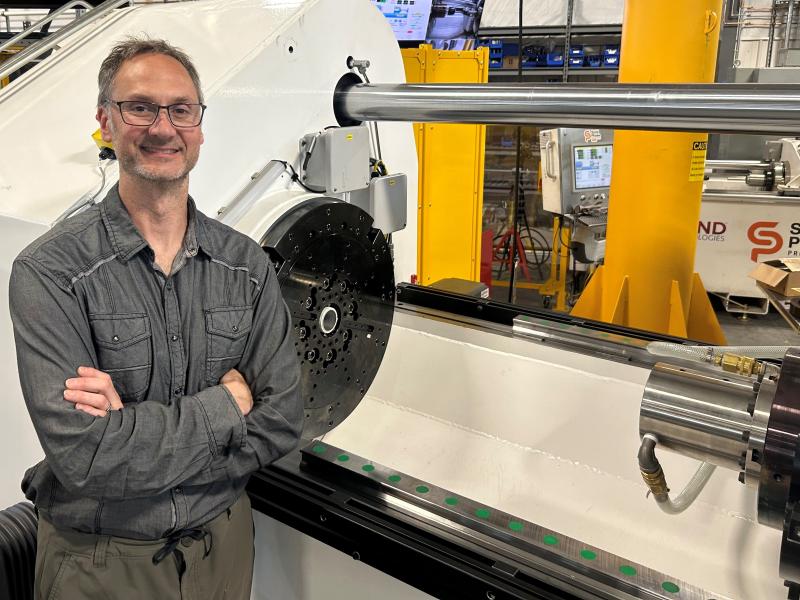

One example of a solid phase processing technique developed by PNNL is the patented Shear Assisted Processing and Extrusion system, also known as ShAPE™. This system enables the manufacture of aluminum or magnesium alloy parts or “extrusions” at significantly lower cost while using less energy and less floorspace. Extrusions from this system offer unprecedented ductility and energy absorption.

PNNL also developed award-winning solid phase processing technologies to join different materials using high strain. PNNL’s friction stir capabilities include the friction stir scribe, which is the only technology that produces a continuous mechanical joint between significantly different materials, like polymer-metal or aluminum-steel. This joining ability eliminates the need for bolts, adhesives, or rivets. Another technology, friction stir dovetailing, is a novel process that allows joining of thicker sheets of aluminum to steel. This dovetailing creates a material with superior joint strength and increased ductility that allows the material to stretch farther before the joint breaks.

In the realm of lightweight materials and associated manufacturing processes, PNNL is leading DOE’s Lightweight Materials Consortium, or LightMAT. This consortium matches 11 national laboratories with key players in the automotive industry. Their goal—to find solutions that overcome lightweighting challenges for on-highway vehicles.

PNNL is also joining forces with Oak Ridge National Laboratory and Argonne National Laboratory in the Joining Core Program. This program is providing the automotive sector with a unique combination of capabilities and tools from the three national laboratories to address key technical gaps and solutions for exploring complex joining problems.

PNNL is a driving force behind materials research for vehicles.