- Best Practices for Equipment O&M

-

O&M Best Practice Issue Discussions

- Advanced Maintenance Approach: Reliability Centered Maintenance

- Applying Key Performance Indicators

- Comprehensive O&M Program

- Contract Challenges and Improvements

- Cybersecurity for O&M Systems

- Existing Building Commissioning Procurement

- Healthy Building O&M

- Integrating and Analyzing Building Information to Support O&M

- Maintenance Approaches

- OMETA: An Integrated Approach to Operations, Maintenance, Engineering, Training, and Administration

- Prioritizing O&M Actions

- Re-tuning Buildings

- Tools

- Glossary

Best Practices for Automatic Transfer Switches Operation and Maintenance

Table of Contents

Introduction

An automatic transfer switch (ATS) is a device that allows safe transfer of electricity from a primary source, usually an electric-utility grid, to a backup source such as an emergency or standby generator. The purpose of an ATS is to reliably provide a load with electrical power from a standby generator to a facility without the possibility of backfeeding the utility grid. An ATS is often used with standby power systems that serve critical loads such as industrial processes, data networks, and other installations such as health care, financial, and military applications.

Executing the necessary operations and maintenance (O&M) for an ATS is crucial for optimized reliability, resilience, and utilization during power outages.

The objective of this equipment O&M Best Practice is to provide an overview of system components, maintenance requirements, and best practices to assure the safe and efficient operation of ATSs. Support organizations should budget and plan for regular maintenance of all ATSs to assure continuous operation.

Description of Technology

In a backup, standby, or emergency power system, an ATS is used to provide continuity in the supply of power between an electrical grid and the designated critical loads served by the backup system. Because the ATS is connected to both primary and backup power, it serves as an intermediary between the load and the sources of power.

The functional elements of the ATS detect a power disruption or failure of the primary source and initiate the process to start a generator, allow it to achieve steady-state operation, verify that requisite voltage and/or frequency has been achieved, and then connect the load to generator power.

There are three general ATS types:

- Open transition (break-before-make): This interrupts the load during the transition between primary and backup power. This is the most common type of ATS, and it is often found with standard backup and standby systems.

- Closed transition (make-before-break): When the load is critical, this type of ATS allows a transfer between two live sources of power without disruption in the critical load during the transition from backup to primary power. This type of ATS is usually found in applications such as data centers, health care, or utility load curtailment systems.

- Delayed transition: This type of ATS operates similarly to the open transition type but affords a delay in load transition and is typically used in situations where residual voltages on inductive loads can dissipate before transition.

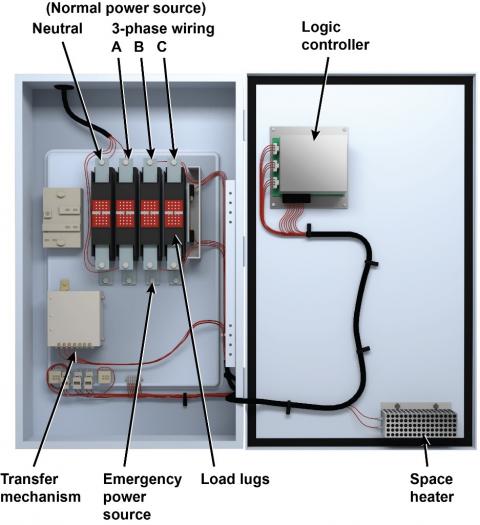

While an ATS works with a generator, they are by design independent from generators. An ATS may be housed in a panel, enclosure, or load center but is typically kept separate from a generator enclosure. Figure 1 highlights a typical ATS and its components.

Key Components

There are three functional components of a typical ATS:

- Transfer mechanism—this device switches the facility and load circuits to and from the utility (normal) or the standby power source (emergency).

- Logic controller—the controller monitors the condition (voltage and frequency) of both sources, determines when to transfer, and provides the signal and command to the transfer mechanism.

- Typical electrical connections—this includes a variety of connection terminals, disconnects, fuse blocks, and source power for the logic controller. These can be arranged in different configurations and form factors.

Safety Issues

Only qualified and experienced personnel should work with an ATS. High voltages are present in ATS systems. All power supplies, breakers, connections, and disconnects must be understood and treated appropriately before any service is attempted. All related code and safety procedures must be understood and followed. Any service provider should follow the manufacturer’s recommendations as well as the safety guidelines found in both the National Fire Protection Association (NFPA) 70E Standard for Electrical Safety in the Workplace (NFPA 2018) and the Institute of Electrical and Electronics Engineers 1584 Guide for Performing Arc Flash Hazard Calculations (IEEE 2018).

Maintenance of Technology

Keeping ATS systems properly maintained through preventive and predictive maintenance will minimize overall O&M requirements, improve system performance, and protect the ATS.

A successful ATS maintenance program will follow the manufacturer’s equipment guidelines, actions, and frequencies for all maintenance activities.

Maintenance Checklist

The example checklist in Table 1 below provides recommended actions and their associated frequencies by ATS component type. This checklist does not supersede maintenance recommendations from the equipment manufacturer, nor is it a replacement for contracted O&M or warranty services. In addition, NFPA 110 – Standard for Emergency and Standby Power Supply Systems (NFPA 2019b) provides guidance on the frequency and testing for critical switchgear such as an ATS.

Table 1. ATS maintenance checklist.

Performance Monitoring

Performance monitoring of an ATS is typically carried out as part of normal O&M activities with documentation. Due to the criticality of the ATS to the larger standby/emergency generation system, tracking and trending of any preventive and predictive maintenance findings is critical to a high-reliability system. Follow any testing guidelines in system documentation provided by the manufacturer.

O&M Cost

ATS systems require preventive and predictive maintenance as well as regular testing to assure the highest reliability. The primary costs for the O&M of ATS systems can be attributed to the cost of labor for technicians to maintain the system. Given the variety of system types and applications, relevant and reliable cost data could not be found.

Additional Support

There are a number of references for operation and safety of the ATS system, including the following:

- NFPA 70B – Recommended Practice for Electrical Equipment Maintenance

- NFPA 70E – Standard for Electrical Safety in the Workplace

- NFPA 110 – Standard for Emergency and Standby Power Systems

- UL 1008 – Transfer Switch Equipment.

Sources of Information

IEEE – Institute of Electrical and Electronics Engineers. 2018. IEEE 1584 Guide for Performing Arc Flash Hazard Calculations. Institute of Electrical and Electronics Engineers, New York, NY. https://standards.ieee.org/standard/1584-2018.html.

NFPA – National Fire Protection Association. 2018. NFPA 70E Standard for Electrical Safety in the Workplace. National Fire Protection Association, Quincy, MA. https://www.nfpa.org/codes-and-standards/all-codes-and-standards/list-of-codes-and-standards/detail?code=70E.

–––. 2019a. NFPA 70B Recommended Practice for Electrical Equipment Maintenance. National Fire Protection Association, Quincy, MA. https://www.nfpa.org/codes-and-standards/all-codes-and-standards/list-of-codes-and-standards/detail?code=70B.

–––. 2019b. NFPA 110 Standard for Emergency and Standby Power Systems. National Fire Protection Association, Quincy, MA. https://www.nfpa.org/codes-and-standards/all-codes-and-standards/list-of-codes-and-standards/detail?code=110.

UL. 2014. UL 1008 Transfer Switch Equipment. Underwriters Laboratories, Northbrook, IL. https://www.shopulstandards.com/ProductDetail.aspx?productId=UL1008_8_B_20141222(ULStandards2).

Actions and activities recommended in this Best Practice should only be attempted by trained and certified personnel. If such personnel are not available, the actions recommended here should not be initiated.

Published July 2021