Physics-Informed Machine Learning for Solid Oxide Fuel Cell System Modeling and Optimization

Team

Jie Bao (PI), Chao Wang, Zhijie Xu, Brian Koeppel

Problem

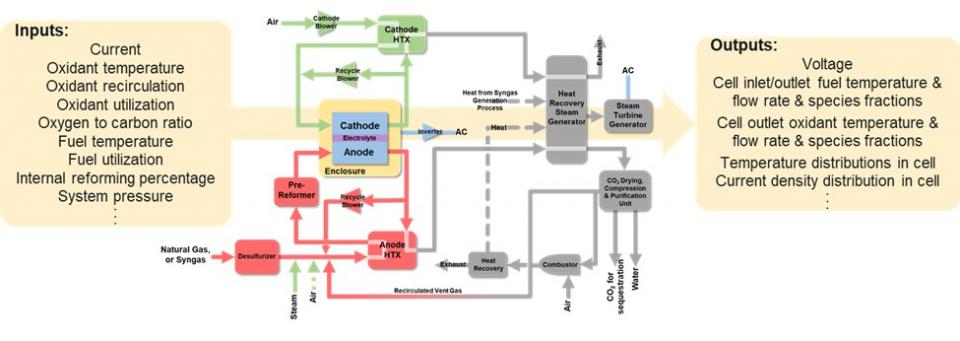

The current reduced order model (ROM), or surrogate for solid-oxide fuel cell (SOFC) performance, is based on Kriging—a traditional regression method. The cross-validated ROM provides efficient predictions with suitable error quantification. The discrepancy of the ROM prediction usually decreases with the increase of training set size. However, for some outputs, the current SOFC ROM does not allow this discrepancy to decrease below ~5 – 10 percent, even with an increased training set size. There is no well-developed method to further decrease this discrepancy. Additionally, traditional machine learning (ML) approaches are mostly developed for data-driven problems, where it is difficult or impossible to establish a physics-based model. Utilizing ML techniques to improve the physics-based model is still challenging.

Approach

ML is popular and rapidly developing. However, successful examples for solving practical science, engineering, or industrial problems are rare. Therefore, we developed an approach of applying ML to address such problems and will use SOFC system modeling and optimization as a demonstration. Pacific Northwest National Laboratory developed the SOFC-Multi-Physics software for the Department of Energy (DOE) Hydrogen and Fuel Cell Technology Office to provide high-fidelity estimates for fuel cell stack performance, which is not computationally efficient enough when integrated into power system-scale models. There are more than 50 input parameters in the stack model that potentially impact fuel cell operation and reliability, and there are over 40 performance outputs to be considered for system interactions. Identifying the influence of key parameters and parameter combinations has been unsuccessful using manual or traditional experimental techniques and regression models. We applied the artificial neural networks ML algorithm to develop the relationship between the model input and output parameters, and to significantly enhance the accuracy and efficiency of this model compared to traditional regression methods.

Results

Several ML applications were explored for SOFC modeling.

- The errors between traditional Kriging regression prediction and true solution can be learned using ML. The ML-trained pattern of the error distribution can reduce the error of Kriging based ROM predictions.

- A deep neural network (DNN) coupled with the mass balance model was developed to significantly decrease the ROM prediction error with fewer training data compared to the traditional Kriging-based ROM and traditional DNN regression approach.

- A DNN regression coupled with a neural network classifier and mass balance model was developed. It provides superior performance at classifying the physical operational conditions for the natural gas fuel cell (NGFC) compared to traditional classification approaches.

- Two kinds of pre-trained DNN transfers were studied and tested. One is transferring DNN for low-fidelity model data to a high-fidelity model. The second is transferring DNN from state-of-the-art NGFC to advanced NGFC system. The capabilities and tools developed in this project will enhance future SOFC studies and has increased the probability of participating in DOE’s new ML and/or SOFC related funding opportunities.

Code, Data, and Related Links

This laboratory directed research and development project’s outcome helped win DOE Advanced Research Projects Agency-Energy—or ARPA-E—DIFFERENTIATE project funding. The codes have been utilized and merged into the ARPA-E ML project, which is open-source released at https://github.com/NGFC-Lib/NGFC-Lib.

Publications

D. Wang, J. Bao, Z. Xu, B. Koeppel, O.A. Marina, A. Noring, M. Zamarripa-Perez, A. Iyengar, E. Eggleton, D.T. Schwartz, A. Burgard, D. Miller. 2021. “Machine learning tools set for natural gas fuel cell system design.” ECS Transactions, 103 2283, https://iopscience.iop.org/article/10.1149/10301.2283ecst