Smart Advanced

Manufacturing

Smart Advanced

Manufacturing

Helping manufacturers make

superior products at lower costs

through process innovations

and robust supply chains

Helping manufacturers make

superior products at lower costs

through process innovations

and robust supply chains

Friction stir wielding machine

Building on a rich history of materials science and engineering, Pacific Northwest National Laboratory (PNNL) is reinventing materials processing and synthesis, ushering in a new generation of advanced manufacturing. The Lab’s Smart Advanced Manufacturing (SAM) program enables the United States to make higher-performance and more affordable products that advance energy resilience and independence. PNNL works with partners across industry, academia, and government to drive the discovery, development, and demonstration of next-generation processes to advance American innovation and competitiveness in manufacturing technologies.

Advancing domestic manufacturing through solid-phase processing

Many of the SAM platforms at PNNL are rooted in solid-phase processing methods: the use of high strain and shear to shape, modify, or combine materials, manipulating their microstructures in ways not achievable by antiquated manufacturing methods.

Solid-phase processing requires no external heat source, instead using friction and other mechanical forces to generate heat and deformation only where needed. This approach drives process intensification, which produces superior properties with less energy required. As a result, solid-phase processing techniques are often more efficient, more economical, and faster than conventional methods—and they enable the creation of superior products with extraordinary properties for the American energy, defense, and transportation sectors.

- American Innovation: SAM’s unique, pioneering technologies produce superior materials and components that often cannot be achieved through conventional manufacturing. Many of the methods are already scalable for industrial adoption, providing an edge to domestic manufacturers.

- Energy Resiliency: The simpler, more efficient, more targeted manufacturing techniques developed through SAM are often able to produce competitive products using far less energy—and the methods often lead to lightweight products that themselves reduce energy costs for the end user.

- Supply Chain Security: Many crucial sectors are increasingly relying on rare, expensive materials procured through precarious international supply chains. SAM manufacturing techniques can produce performant—and often superior—products with lower-cost, abundant materials, reducing reliance on critical materials.

- Economic Competitiveness: From feedstock materials to energy use to process efficiencies, SAM technologies have the potential to drastically reduce the cost of domestic manufacturing in a range of industrial sectors without sacrificing product quality.

Core capabilities

The SAM facilities at PNNL house a wide range of materials science and engineering experts; manufacturing platforms; and advanced characterization, simulation, testing, and analytics. These are some of the platform technologies pursued by SAM:

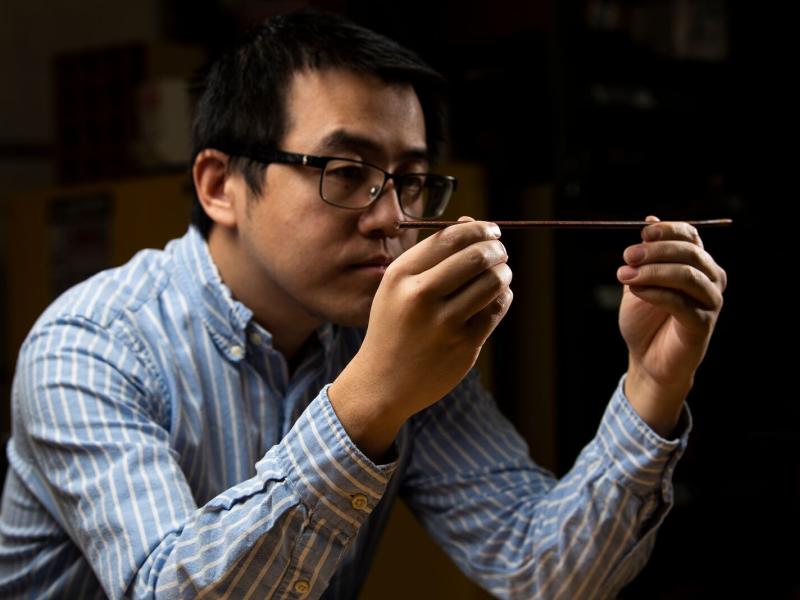

- Shear Assisted Processing and Extrusion (ShAPE™) – SAM’s flagship technology, the patented, award-winning ShAPE technique, extrudes materials by using a shearing action at the face of the billet to locally heat and plasticize the material before it is pressed through a shaping die to produce wire, bar-stock, tubes, forging blanks, and other complex geometric extrusions. This technique—which is capable of both direct and indirect extrusion—imparts significantly more deformation into the material than conventional extrusion, offering a number of unique mechanical and functional advantages.

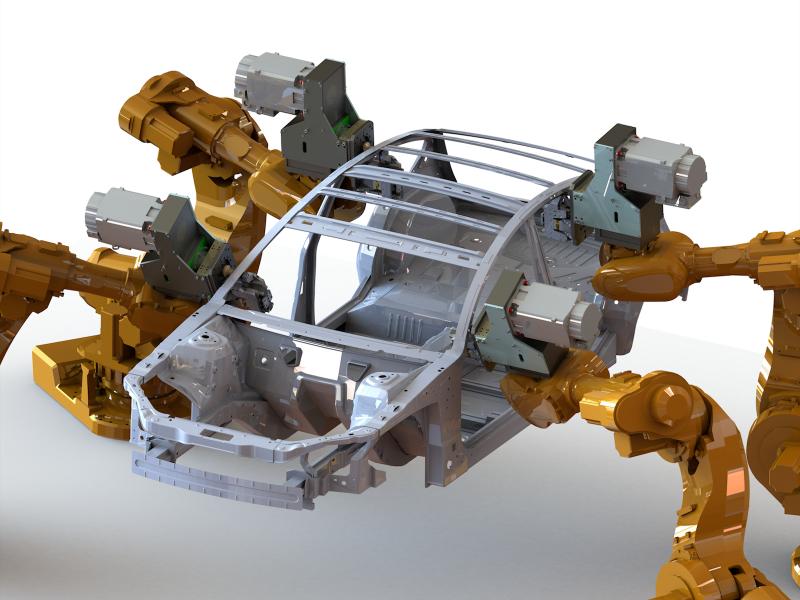

- Friction Stir – Friction stir techniques involve using a spinning tool to generate intense levels of deformation and processing conditions that are far from equilibrium. They can be used for joining, local processing, and additive manufacturing. Friction stir welding requires a small fraction of the energy of conventional fusion welding, dramatically reducing costs. Friction stir techniques can join dissimilar materials that cannot be joined by other methods, enabling the production of next-generation products.

- Cold Spray – This is a solid-phase metal deposition process used for coating or additive manufacturing that can deliver superior material properties. During cold spray, powder is propelled through a heated, pressurized carrier gas stream and accelerated to supersonic speeds before it exits a nozzle and is deposited on the target material. Continuous deposition of the powder produces a bulk structure. Cold spray can be used for repair or improvement—such as increasing a component’s resistance to corrosion.

Real-world applications

SAM technologies have broad industrial applications, including in automotive manufacturing, industrial processes, nuclear power, electricity generation, buildings and construction, oil and gas exploration, aerospace, and national security. Industry and academic researchers are encouraged to collaborate with PNNL and leverage its wide range of ongoing research and development projects in the manufacturing space. For specific applications and to further demonstrate them in a variety of industrial settings, please contact PNNL’s Transportation and Industry Program Office.