Geologic Carbon Storage

Scientific and technological advancements to safely and permanently store CO2

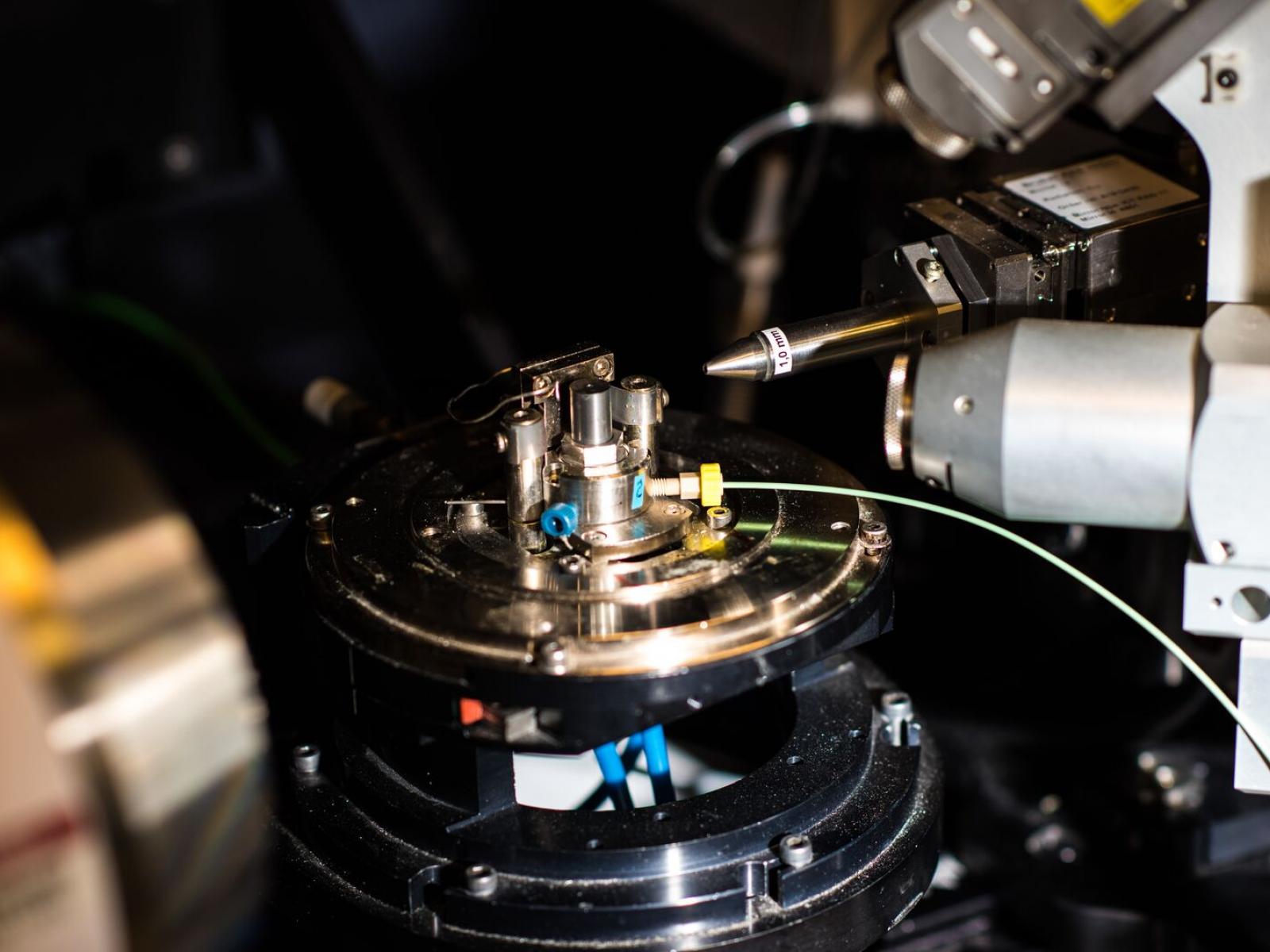

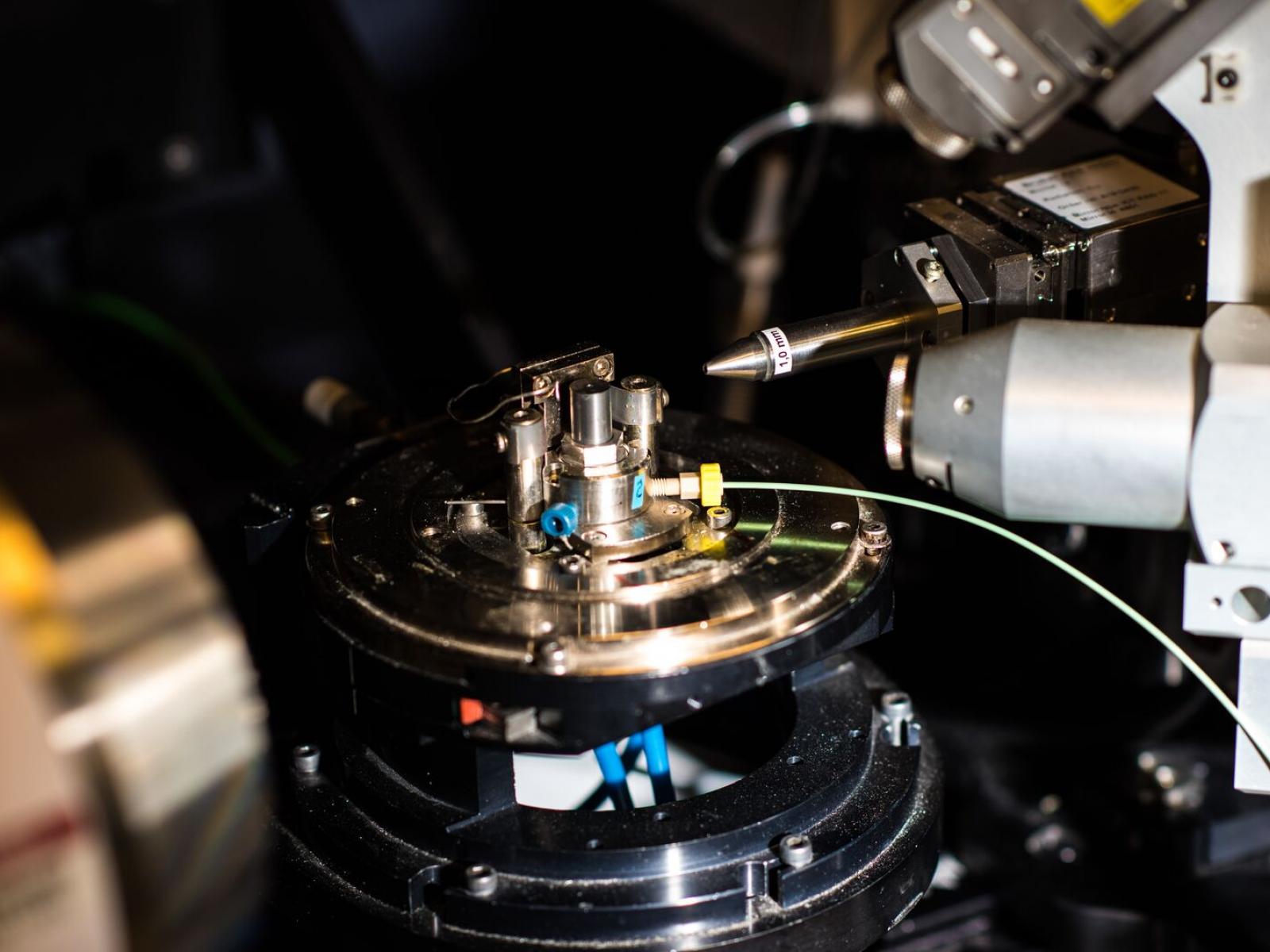

The X-ray diffractometer (XRD) is capable of examining materials under extreme conditions.

Andrea Starr | Pacific Northwest National Laboratory

Scientific and technological advancements to safely and permanently store CO2

The X-ray diffractometer (XRD) is capable of examining materials under extreme conditions.

Andrea Starr | Pacific Northwest National Laboratory

Carbon dioxide (CO2) production from the burning of fossil fuels (oil, gas, and coal) accounts for more than 80 percent of greenhouse gas emissions in the United States. About one-third of those CO2 emissions come from coal or gas power plants.

In partnership with industry, scientists have been working for decades to identify a way to capture and permanently store CO2 so that it never makes it into the atmosphere.

A collection of technologies, known as carbon capture, utilization, and storage (CCUS), shows the most promise for accomplishing this large task.

Carbon capture, utilization, and storage involves capturing waste CO2 from large point sources—such as fossil fuel power plants—transporting it to a storage site, and injecting it into an underground geological formation, called a reservoir. Geological reservoirs offer sufficient depth, thickness, porosity, and permeability to permanently and safely contain the CO2 (for at a least 1,000 years).

PNNL researchers are part of a team working to advance our scientific understanding of how CO2 reacts with rocks and minerals when it is injected into the subsurface of a reservoir. Armed with this knowledge, we can improve the accuracy of models that will be used to predict the fate of CO2.

Additionally, through various partnerships in the United States and abroad, PNNL is helping characterize suitable geological sites for long-term storage of CO2 and develop new monitoring and data management methods for these sites.

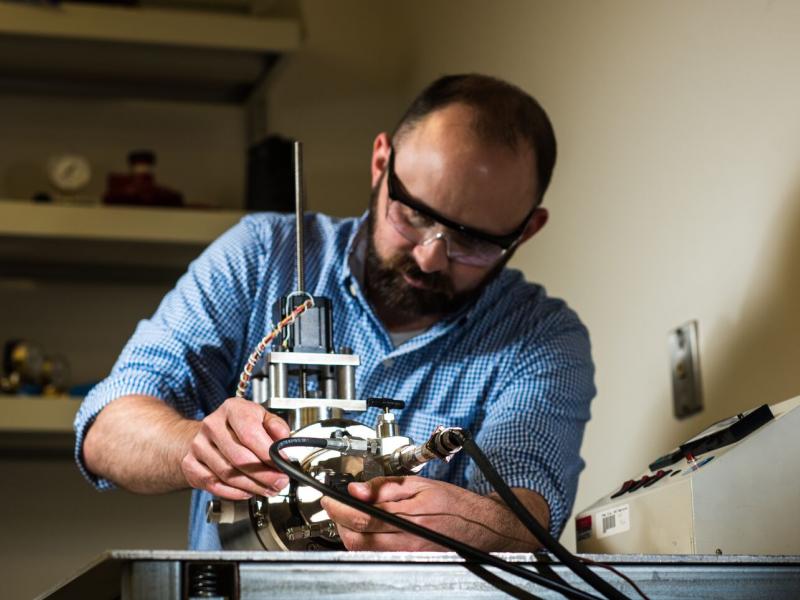

Equipment used for a Carbon Capture program, which is developing novel solvents for better capturing CO2 from a coal powered power plant.

A PNNL LDRD program is developing a capability for measuring fracture propagation in materials under extreme conditions--also known as raman double torsion capability.

This uniquely designed Laboratory Continuous Flow System (LCFS) is able to evaluate various aspects of typical, analogous industrial absorption and stripping operations such as novel CO2 capture solvents, various packing materials, and a wide range of process conditions at a much smaller scale.

Equipment used for a Carbon Capture program, which is developing novel solvents for better capturing CO2 from a coal powered power plant.

A PNNL LDRD program is developing a capability for measuring fracture propagation in materials under extreme conditions--also known as raman double torsion capability.