Metering Program Objectives

Before deploying advanced metering infrastructure at a facility, an organization should define the objectives of the metering program. Objectives should reflect an organization’s requirements and specific interests in energy and water management. Examples of possible objectives include:

- Identify system-specific operational efficiency opportunities (e.g., upgrade fume hoods in all laboratory space or downsize irrigated landscape at all buildings by 50 percent)

- Fully enable energy and water bill allocation throughout an entire facility

- Effectively manage electric loads to minimize costs under a time-based rate schedule

- Identify equipment malfunction or impending malfunction, such as in critical use facilities like hospitals or data centers

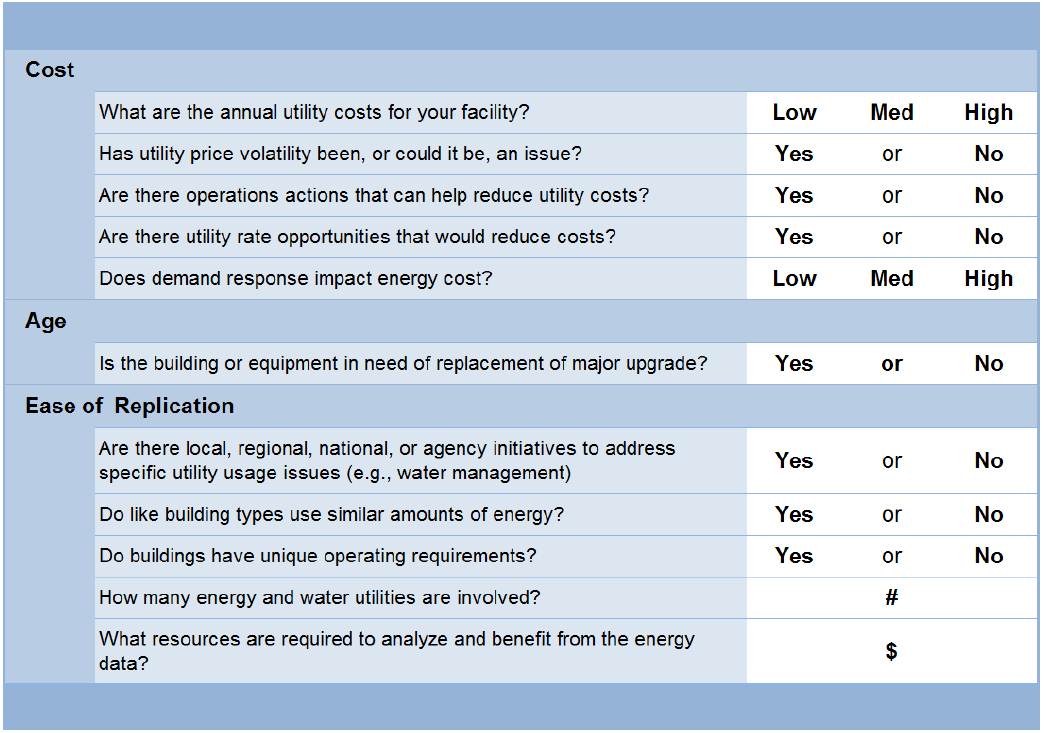

Table 1 has example questions to facilitate identifying organization metering program objectives.

Identify Staffing, Funding, Information Technology, and Data Needs

To develop a metering program, an organization needs to understand what funds are available, when they will be available, how additional funds can be obtained, and how the funds can be used. Funds are needed to prioritize the building inventory, specify the advanced meters needed, purchase and install the advanced meters, connect the advanced meters to a data collection and management system, purchase or develop analysis tools, and develop and maintain the staffing resources described above.

The value of a metering program lies in analyzing data and communicating results so that action can be taken. Security requirements vary widely across organizations and are becoming more rigid. Information technology (IT) staff must be engaged in the development of the metering plan to determine whether there are cybersecurity limitations on the type of advanced meters and communication equipment that can be used. One important cybersecurity concern to address is whether advanced metering infrastructure data can be transmitted over an existing agency IT network, or if a separate network is required.

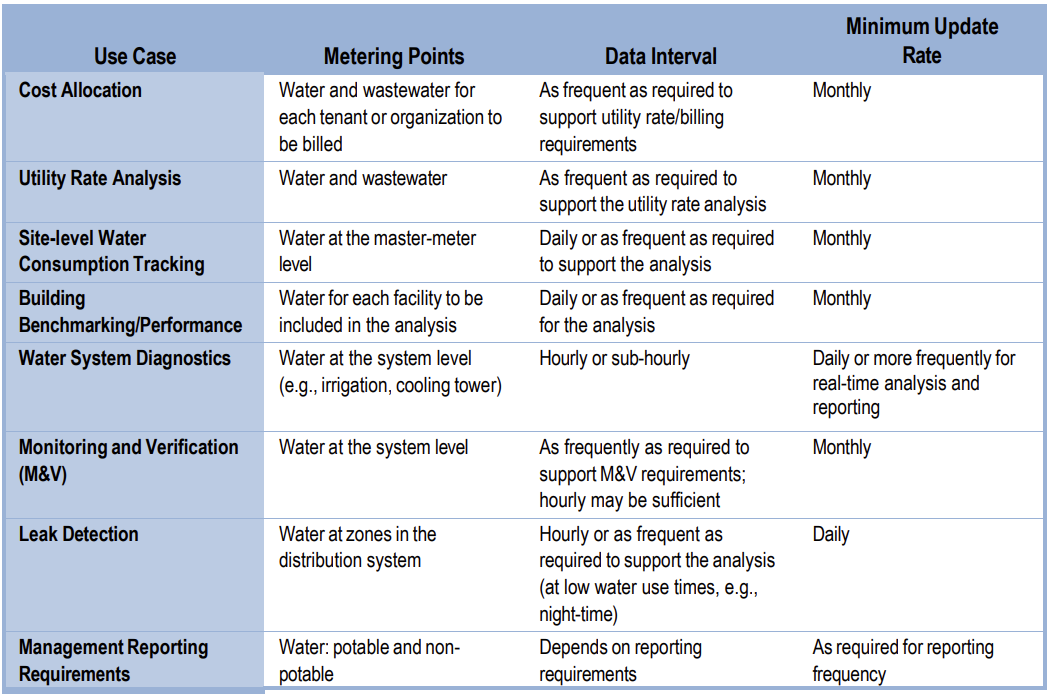

Starting with the end in mind is useful with metering planning, particularly when considering anticipated data needs. By considering desired outputs and actionable information at the outset of metering planning, the system development and planning will become more focused. Table 2 presents the types of data required to support various water metering use cases.

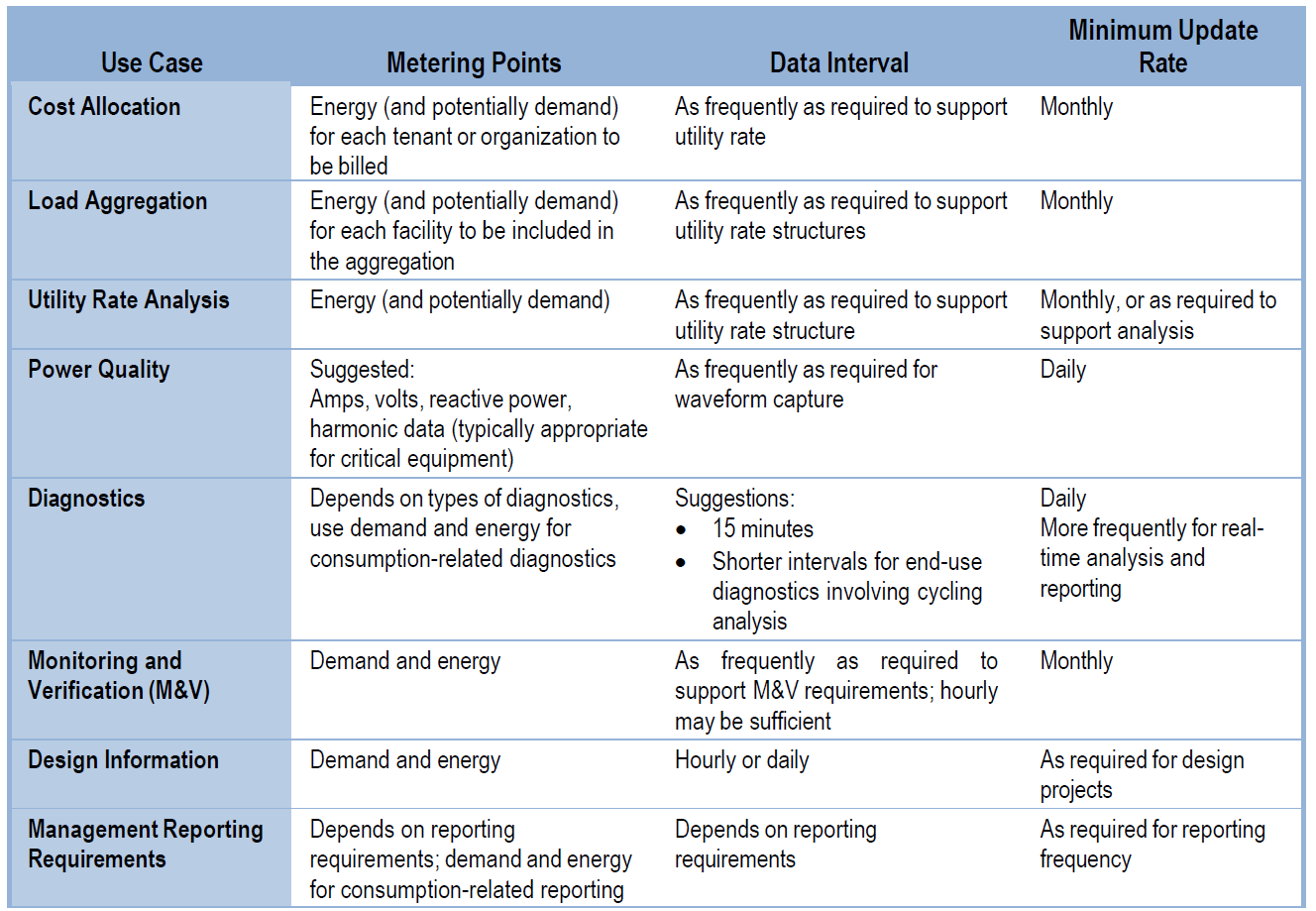

Table 3 presents the types of data required to support various building electricity metering use cases. Not included in this table are the data needs for on-site load shedding and utility-sponsored demand-response programs. In each program, metering should be provided to accurately quantify energy use at the system level or at the point of use being affected.

Estimate Staffing and Resource Requirements

Staffing resources to install, maintain, and operate a metering system, as well as analyze the metered data, are critical to a successful metering program. Staff need to be trained and given time to operate and maintain the metering equipment and system. Training and time should also be allotted for analyzing the metered data to gain the benefits of the metering system.

To achieve any value from metering systems, there needs to be well-defined data usage and system maintenance commitments. Each of these entails a different skill set and resulting resource requirements; each necessitate a commitment of time and resources for the program to be successful.

Assessing the costs to perform data analysis and system maintenance is difficult and highly dependent on the specifics of the system. The number and type of meters used will impact maintenance requirements and decisions on how to receive and process data will impact analysis costs.

Data Analysis. Prior to receiving metered data, consider establishing a meter data management system. These systems can be site-generated spreadsheet/database tools or commercially available software packages, such as an energy management information system. Whichever solution is chosen, it is important to automate as much of the data access and analysis functions as possible to minimize future data management costs.

Once the metering system is connected and reporting, data can accumulate quickly. For example, a site with 50 advanced energy meters reporting at 15-minute intervals will result in 4,800 data points per day, 33,600 data points per week, and over 1.7 million data points per year.

To estimate resource commitments for data analysis, consider the following example:

- System assumption: A total of 50 building-level and end-use meters serving electric, natural gas, and steam loads

- System analytical outputs: Daily plots of energy use presented as time-series in a dashboard

- Daily time series electric, natural gas, and steam plots

- Alarm sets enabled to highlight out-of-range values

- Exception report comparisons, day-of-the-week, month-of-the-year

- Drill-down capability to 15-minute reporting

- One-time resource commitment: System training

- Staff training on system design, access, and applications: 1 – 2 days

- Staff access and system navigation mastery: 1 week

- Daily access for system review and assessment: 2 hours

- Weekly resource commitment: System use

- Commitment for data access, review, and assessment: 10 hours/week

Notes: The initial setup of the analytical outputs will take additional time to develop and make useful for your organization’s analysis needs. Once developed, the analytical outputs can be reused. Actions resulting from data assessments will require additional time/resources.

System Maintenance. With the advent of solid-state components and meters, routine system maintenance has been reduced but not eliminated. Maintenance requirements will vary by meter type and should be included in standard preventive maintenance routines.

- One-time resource commitment: System training

- Staff training on metering technology and function: 2 – 4 hours per meter type

- Monthly resource commitment: Functional inspections

- Monthly commitment for preventive maintenance activities: 5 hours/month

Note: Monthly inspections do not include manufacturer-recommended calibration activities.

Special Metering Considerations

The Federal Metering Guidance recommended prioritization method emphasizes the need to meter data centers, on-site energy generation, and other energy and water intensive buildings/facilities. This section uses data centers and on-site energy generation as examples of special metering considerations that may exist within an organization.

Data Centers. The energy use associated with data centers has increased markedly since 2000. That increase will continue in the future as a result of expanding facility automation and equipment upgrades that add new capabilities and create the need for additional servers and the space to house them. Power density and the effective cooling are fast becoming defining issues for the data center operators and energy managers. Thus, the need to improve energy efficiency can no longer be ignored.

While equipment manufacturers are responding to these concerns with equipment that has greater computing capability with less power input and more efficient cooling systems, the need for additional cooling capacity will still be required. This will require more concerted effort to meter energy consumption and ensure available cooling capability will be available. While some data centers are stand-alone buildings, most data centers are distributed through existing buildings to meet individual user needs; others are a major portion of a larger building that serves the entire site. FEMP offers a variety of resources for implementing energy efficiency measures in data centers.

On-site Power and Water Production. There has been an increased emphasis on the need for on-site generation of power and water to increase resilience and support site energy independence. As a result, there has been an increase in the assessment, design, and implementation of various onsite generation resources. For power this can include fuel cells, renewable technologies, solar hot water, solar photovoltaic, wind power, geothermal power, biomass, and methane gas, and combined heat and power systems. On-site water sources can include fresh water (surface or groundwater) and alternative water (condensate capture, rainwater harvesting, grey water, and reclaimed wastewater).

These on-site systems require that advanced metering systems are used to capture time-interval data on the amount of power or water produced.

Electric Vehicle Charging. Federal agencies are responsible for accurately measuring and reporting electricity used to charge zero emission vehicles from electric vehicle supply equipment (EVSE) installed at federal facilities. To effectively track EVSE electricity use at federal facilities, several options are available:

- Metering or submetering: Depending on the number of EVSE units, they can be integrated into the building's existing electrical grid, or they may be serviced through their own interconnection where there would be a dedicated utility meter exclusively for the EVSE units. When EVSE units are a part of the building load, the EVSE circuits may have a dedicated panel, or they may share a panel with other building loads. For EVSE on a dedicated panel, the entire panel load may be measured from a single meter. If the panel is used for more than just EVSE, then a series of submeters could be installed to collect data at just the dedicated circuits.

- Networked EVSE: Installing networked EVSE units provides built-in data management and metering capabilities, facilitating accurate tracking and control of charging.

- Telematics: This option involves using vehicle telematics systems for tracking. However, it requires that only fleet vehicles with telematics be allowed to charge at the EVSE units and may entail additional monthly costs. Note that this option requires that the agency has access to the telematics charging data for all fleet vehicles using the EVSE.

For more information on measuring and reporting electricity use for EVSE, see FEMP’s Best Practices for Federal Facility Measurement and Reporting Electricity from Electric Vehicle Supply Equipment.