Advanced Metering System Costs and Savings Potential

Advanced metering system costs vary widely for many reasons: equipment specifications and capabilities, required infrastructure, site-specific design conditions, local cost factors, etc. For these reason, this guide does not present specific cost estimates. Instead, it identifies the main cost components that should be addressed when developing a metering cost estimate.

The metering cost estimate can be separated into three main categories: capital, labor, and recurring costs.

- Capital refers to the cost of the meters and all materials required to support their installation:

- Advanced meter purchase cost is the purchase price depends on the required features selected, such as accuracy, memory, and mounting.

- Ancillary devices, such as current transformers, potential transformers, and safety switches, are required by electric meters. These devices may be built into the meter or can be specified separately. Natural gas, steam, and water meters may require filters or strainers, temperature and pressure compensators, flow straighteners, and straight pipe runs. These devices affect design, practicality, cost, and may influence the type of meter that can be specified for a given application.

- Communications modules can be incorporated into meters and there are several types. Communication may be wired or wireless, analog, digital, one- way or two-way, periodic, or continuous. The meter’s communication module may include a handheld reader communicator, telephone modem, cellular modem, radio transceiver, power line carrier modem, Ethernet modem, Wi-Fi, hard wire (RS232 or RS485), or supervisory control and data acquisition interface. Communications modules are usually specified with the meter.

- Miscellaneous supplies are small compared to other hardware line-item costs, and can include supplies, such as wire, conduit, and junction boxes necessary to complete the installation. Also consider the power supply to the meter and data transmission system.

- Labor covers the time involved for a crew to install all of the hardware, connect the communications module, perform operational testing, and inspect the functionality of the metering system. Examples of variables in the labor costs include the type of meter being installed (utility being metered and if the meter is intrusive or non-intrusive), service shutdowns that may need to be accomplished during off-hours, and trenching requirements for running cable.

- Recurring costs are planned regular costs that support the ongoing operation of the meter/metering system and include the following:

- Monthly communications fees – These fees will vary based on the communications method selected.

- Data collection and storage – Computer hardware and software will require some level of maintenance and upkeep.

- Data analysis – Data needs to be analyzed on a regular basis (daily and/or weekly) with findings and recommendations issued.

- Operation and maintenance – Meters require periodic calibration and testing.

Visit the Advanced Meter Cost-Effectiveness Calculator website to assist in evaluating the cost-effectiveness of advanced metering at a particular building or site.

The use of energy and water data has been shown to result in changes to operations and maintenance practices, and the identification of projects that improve the energy efficiency of building equipment and systems. By implementing these changes, buildings have shown efficiency improvements of 10 – 20 percent.

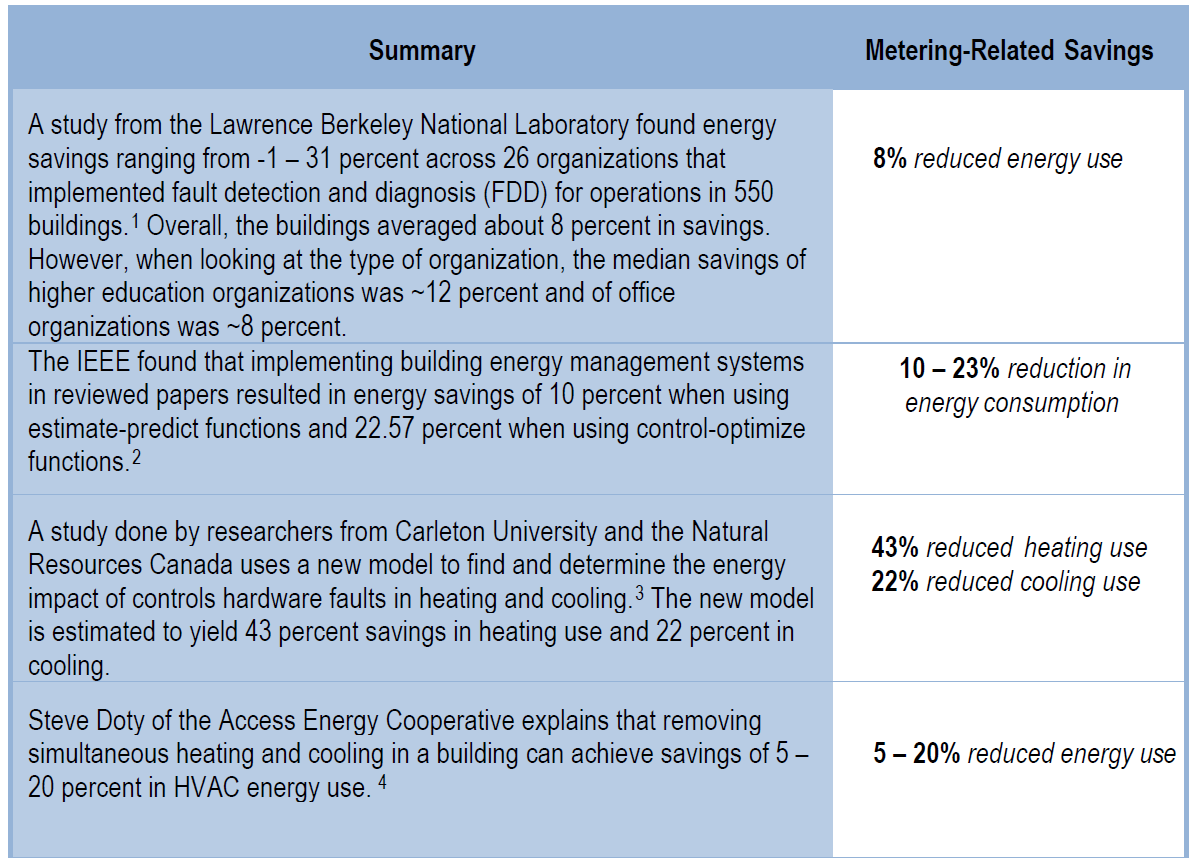

Table 1 presents metering-related savings ranges based on different uses for metered data. Typically, only success stories are published, thus the metering savings ranges may not be representative of the typical result. Savings for a specific building will vary based on the current health of the building’s systems and the ability to successfully implement, measure, and sustain a positive change. If no action is taken as a result of the metered data analysis, then no lasting energy reduction would be expected.

Even greater savings can be realized when the data are used to support actions to optimize building operations. This includes:

- Verifying or re-tuning building and/or equipment startup and shutdown times

- Actively managing electric demand to minimize the impacts of time-based demand charges

- Determining existing and on-going operating conditions for use in building commissioning studies

- Continued verification of implemented building commissioning activities