Projects

Thrust 1 Projects

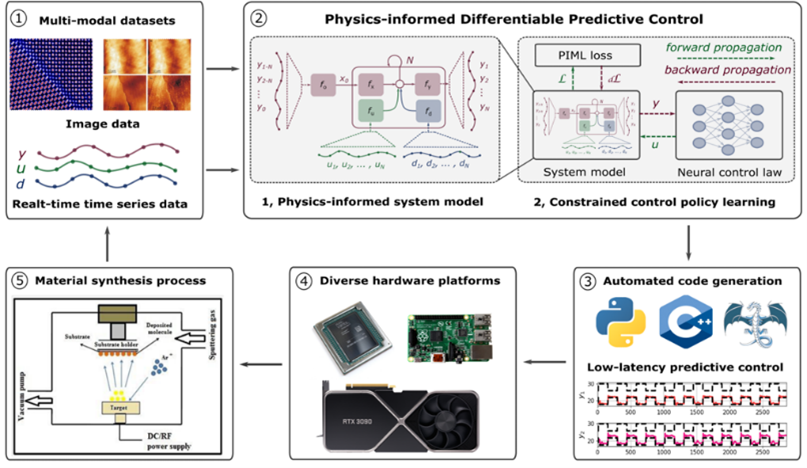

Differentiable Programming for Low-latency Control of Material Synthesis Processes

Principal Investigator: E. King

This project seeks to develop a novel theoretical and algorithmic framework for differentiable digital twins of multiscale physics present in AT SCALE material synthesis projects. This framework will then allow for the design of fast predictive control strategies deployable on edge devices with low-latency constraints. These developments will enable low-latency closed-loop autonomous control of material synthesis processes across ongoing AT SCALE projects through active collaboration. The project will initially focus on two material synthesis process control use cases (epitaxial synthesis and laser processing) that range in data set types and the availability of information for physics-based digital twin development.

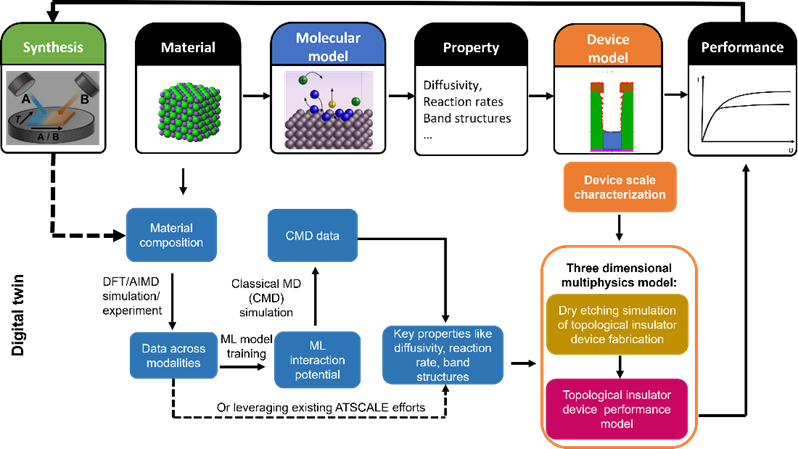

Digital Twin Enabled Accelerated Development of Topological Insulator

Principal Investigator: Z. J. Xu

This project will investigate the science behind the fabrication topological insulators into devices. We will identify appropriate materials, handling procedures, chemistry, and lithography while keeping synthesis constant to establish a fabrication workflow based on available Pacific Northwest National Laboratory capabilities. This will enable the fabrication of devices that can be characterized and used to develop a figure of merit based on the process workflow. This information will be fed into a digital twin framework involving a suite of models to identify the relationships between material composition, structure, fabrication parameters, and device performance. This requires integrated multiscale and multiphysics models, their AI surrogates, and experiment/testing data. The digital twin will enable rapid prediction of device performance for given fabrication properties and will eventually include material synthesis properties.

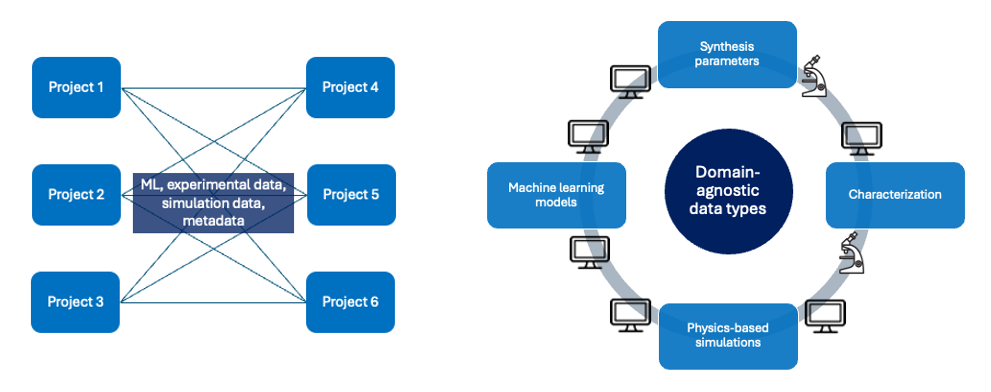

DECENTRALIZED DATA MESH FOR AUTONOMOUS MATERIALS SYNTHESIS

PIs: S. Allec, N. Tallent

The lack of domain-informed composable data management concepts for materials science is a fundamental barrier to exploiting multi-modal materials data. This project will define and design the necessary data management concepts, realized as general building blocks of data services that compose into larger units, interface with a scientific data mesh, and are quickly customized to meet the varying needs of domain scientists. The work will develop helpful data management services and use them to compose customizable prototype data pipelines for each project. A pilot project will work with two other projects to build a prototype data mesh that can be expanded in future work.

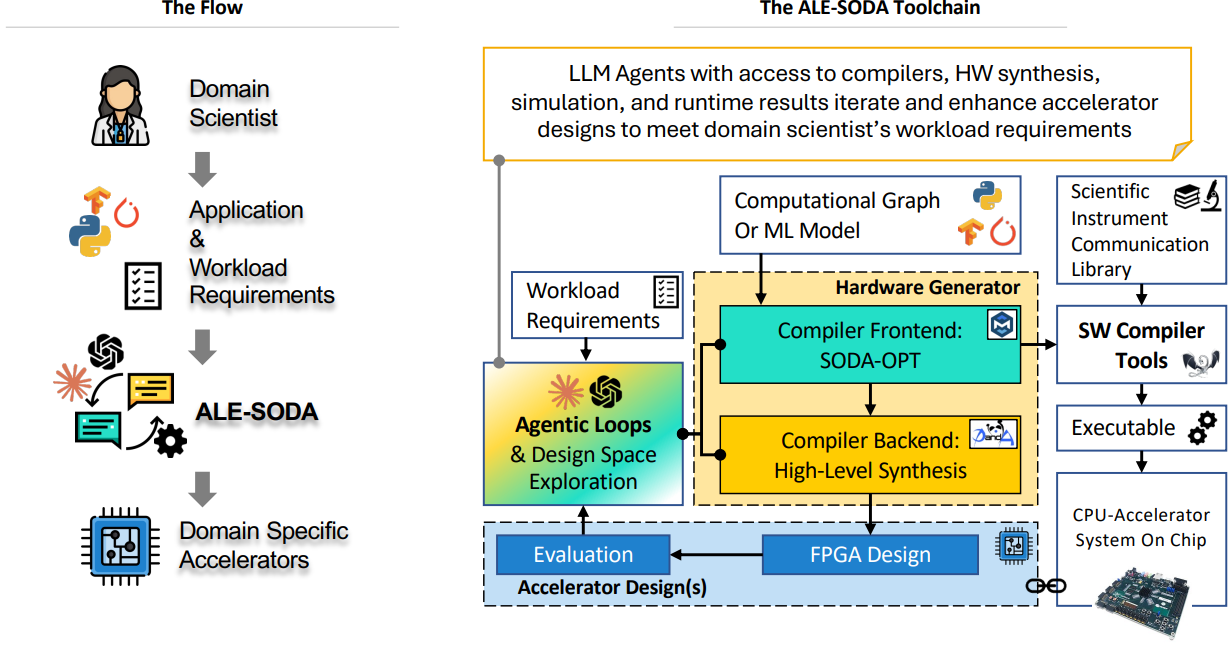

Agentic Loops for Enhancing Software-Defined Accelerators and Their Deployment in Edge Scientific Workflows

PIs: N. B. Agostini

The ALE-SODA project will develop an agent-driven system that extends the software-defined-accelerators toolchain (SODA) to automatically generate and deploy custom hardware accelerators for real-time scientific experimentation on field-programmable gate array system-on-chip (FPGA-SoC) devices. These accelerators will enable scientific workflows to execute domain-aware machine learning models or linear algebra computational graphs directly at the edge, supporting the real-time constraints of closed-loop experimentation. Supported by a co-developed instrument–FPGA-SoC communication library, the initial use case targets the electron energy loss spectroscopy processing pipeline in next-generation closed-loop materials discovery and low latency characterization.

Thrust 2 Projects

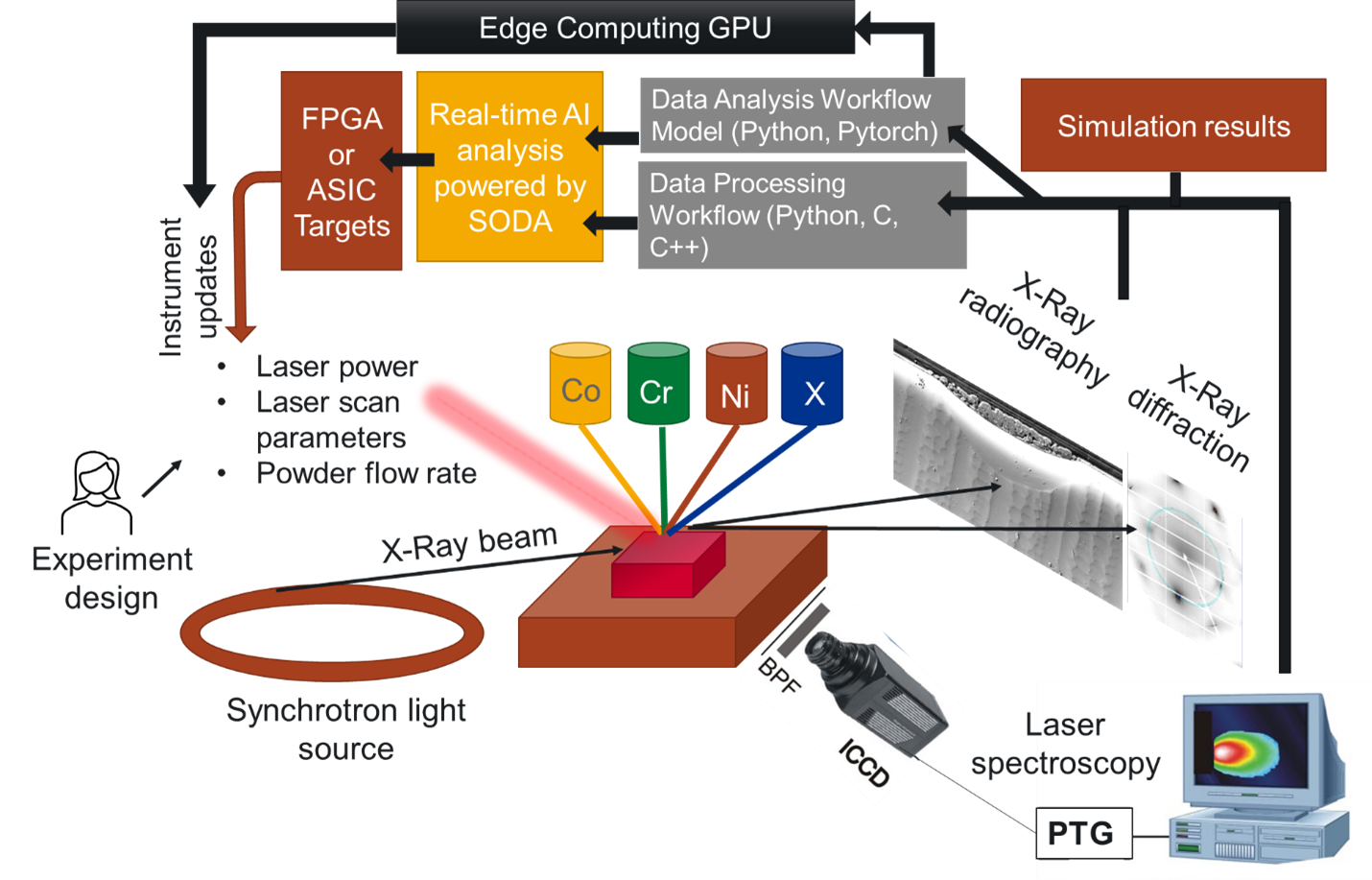

Automated In Operando Experimental Analysis of Far from Equilibrium Phase Evolution During Additive Manufacturing of Multiple-Principal Element Alloys

Principal Investigator: A. Devaraj

This project seeks to advance cutting-edge in situ experimental techniques and data processing pipelines to enable precise detection of phase evolution in multiple-principal element metal alloys undergoing laser processing. By leveraging these enhanced capabilities, the system will facilitate rapid interpretation of observed data and offer real-time recommendations for adaptive laser process parameters, enabling the formation of optimized microstructures with superior properties. Additionally, the project emphasizes the integration of Python-based data processing methods to analyze in situ synchrotron X-ray imaging and diffraction results with low latency, employing ML models for efficient data analysis and interpretation. These insights will feed into an edge computing framework to deliver optimized process controls, advancing the field of autonomous materials processing and property prediction.

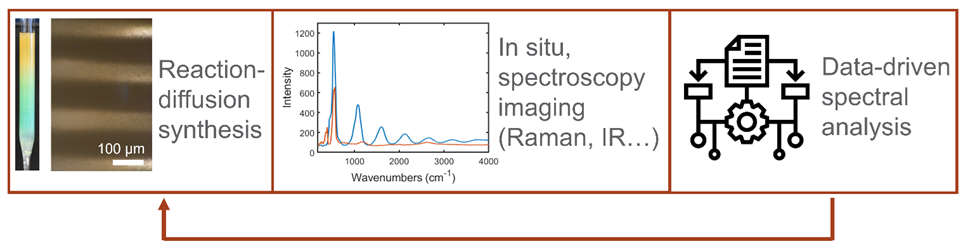

Autonomous Materials Discovery in Nonequilibrium Reaction-Diffusion Systems

Principal Investigator: E. Nakouzi

Non-equilibrium materials synthesis is the modus operandi in natural and biological systems; however, it remains beyond traditional synthesis techniques due to the immense and challenging phase space of parameters that can potentially be controlled. To solve this problem, we will develop an autonomous experimentation capability to explore, control, and optimize nanomaterials synthesis in non-equilibrium environments. Specifically, we will program reaction-diffusion precipitation systems to create multicomponent metal oxide nanomaterials with controlled chemistry, size, morphology, crystallographic phase, and spatial distribution. The vast experimental parameter space will be navigated using an iterative feedback loop informed by real-time spectroscopic data and modeling. We anticipate three major components toward achieving this autonomous experimentation capability: 1) synthesis using reaction-diffusion in liquid-gel systems, 2) real-time characterization of product evolution using spatially resolved Raman and other spectroscopies, and 3) real-time data-driven modeling to benchmark experimental products against a spectral database.

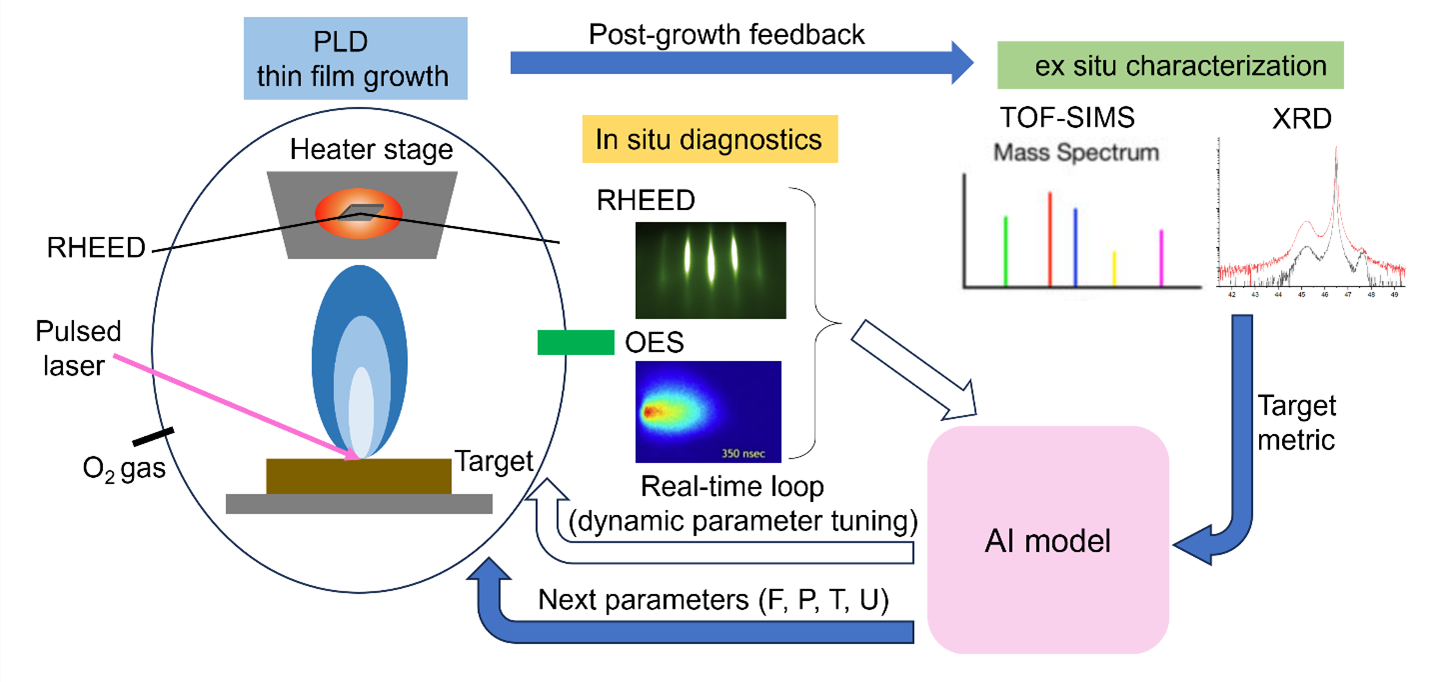

AI-DRIVEN AUTONOMOUS STOICHIOMETRY CONTROL IN PLD THIN FILM SYNTHESIS

PI: L. Wang

Precise stoichiometry control is critical for growing functional materials. This project will develop an AI-driven, autonomous synthesis approach for pulsed laser deposition (PLD) by combining real-time laser ablation–induced plasma diagnostics via optical emission spectroscopy (OES) to monitor the plume before it reaches the substrate and reflection high-energy electron diffraction (RHEED) to monitor film growth on the substrate surface. The case study will address precise lithium stoichiometry control during thin film growth, relevant to energy storage, materials science, and electronics applications. The autonomous synthesis approach will enable precise stoichiometry control and dynamic adjustment of deposition parameters, accelerating the development of advanced materials.

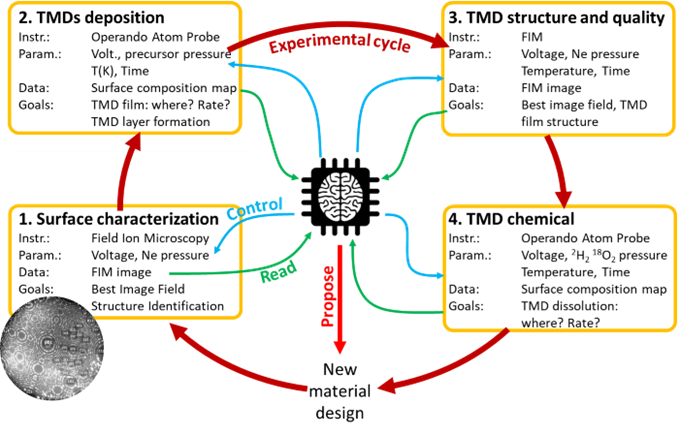

Auto FIM/OAP for Imaging Transition Metal Dichalcogenides (TMDs) Synthesis at the Nanoscale: Towards Enhanced Control of TMDs Fabrication

PIs: S. Lambeets, M. Ziatdinov

Transition metal dichalcogenides (TMDs), such as WSe2 and MoS2, are 2D materials with promising electronic and catalytic properties as well as great resistance and mechanical flexibility, which opens them to a wide range of applications. However, synthesizing TMD films with high control remains a delicate process. This project aims to explore the electric field-assisted synthesis of WSe2 on W surfaces, using a combination of field ion microscopy (FIM) and operando atom probe (OAP). AI-driven control of the FIM/OAP system will be optimized to adjust synthesis parameters (precursor pressure, voltage, temperature) in real time based on OAP experimental measurements. The goal is to understand how electric fields can trigger and influence the TMD synthesis mechanism at the atomic scale, improving the quality and control of TMD films.

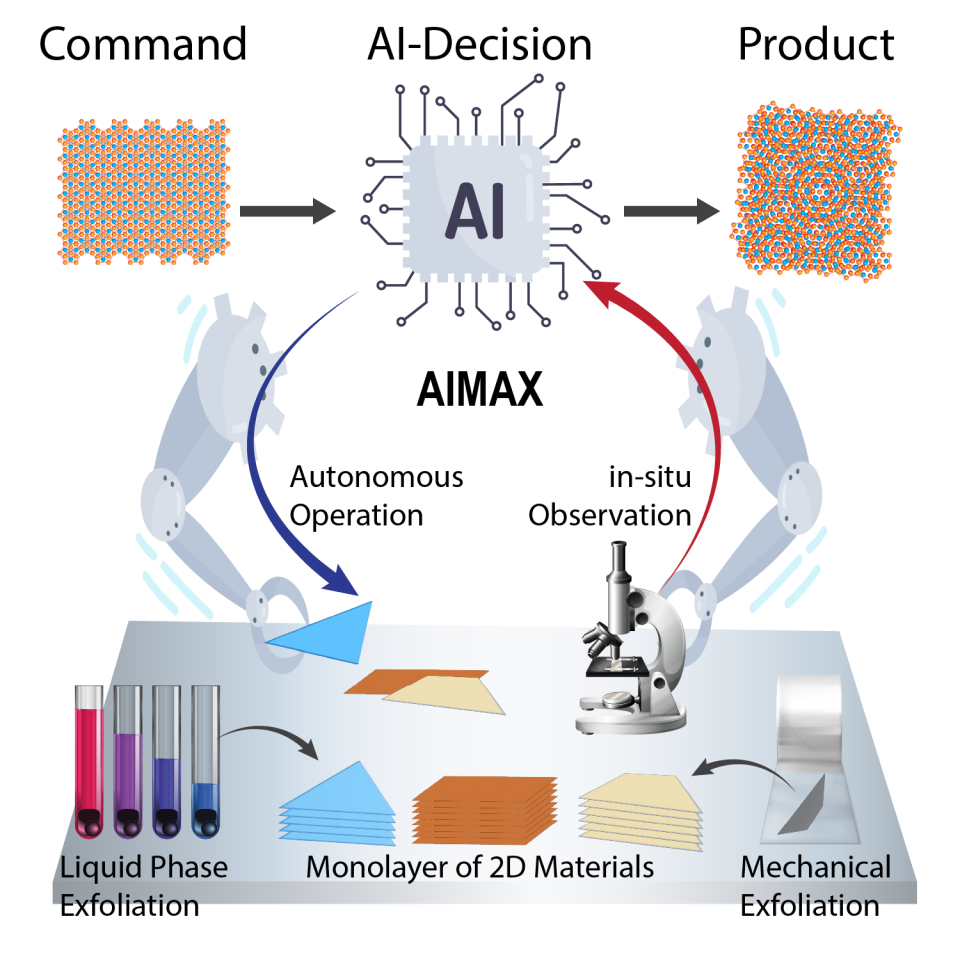

Artificial Intelligence powered Material Autonomous Exfoliation for Advanced Two-Dimensional Heterostructures

PI: C.-F. Wang

Two-dimensional (2D) materials exhibit unique low-dimensional physical properties, positioning them as highly promising candidates for next-generation microelectronics and quantum computing devices. Scaling the synthesis of high-quality monolayers of 2D materials and streamlining the precise transfer process for heterostructures remain time-consuming and yield low productivity. This project aims to revolutionize the fabrication workflow of 2D materials through the Artificial Intelligence-powered Material Autonomous Exfoliation (AIMAX) platform. AIMAX will leverage predictive modeling, automation, and multimodal characterization to help address critical gaps in the synthesis, exfoliation, and transfer processes necessary to create precise 2D material heterostructures and devices.