PNNL’s Spin on Earth Day Science and Technology Innovations

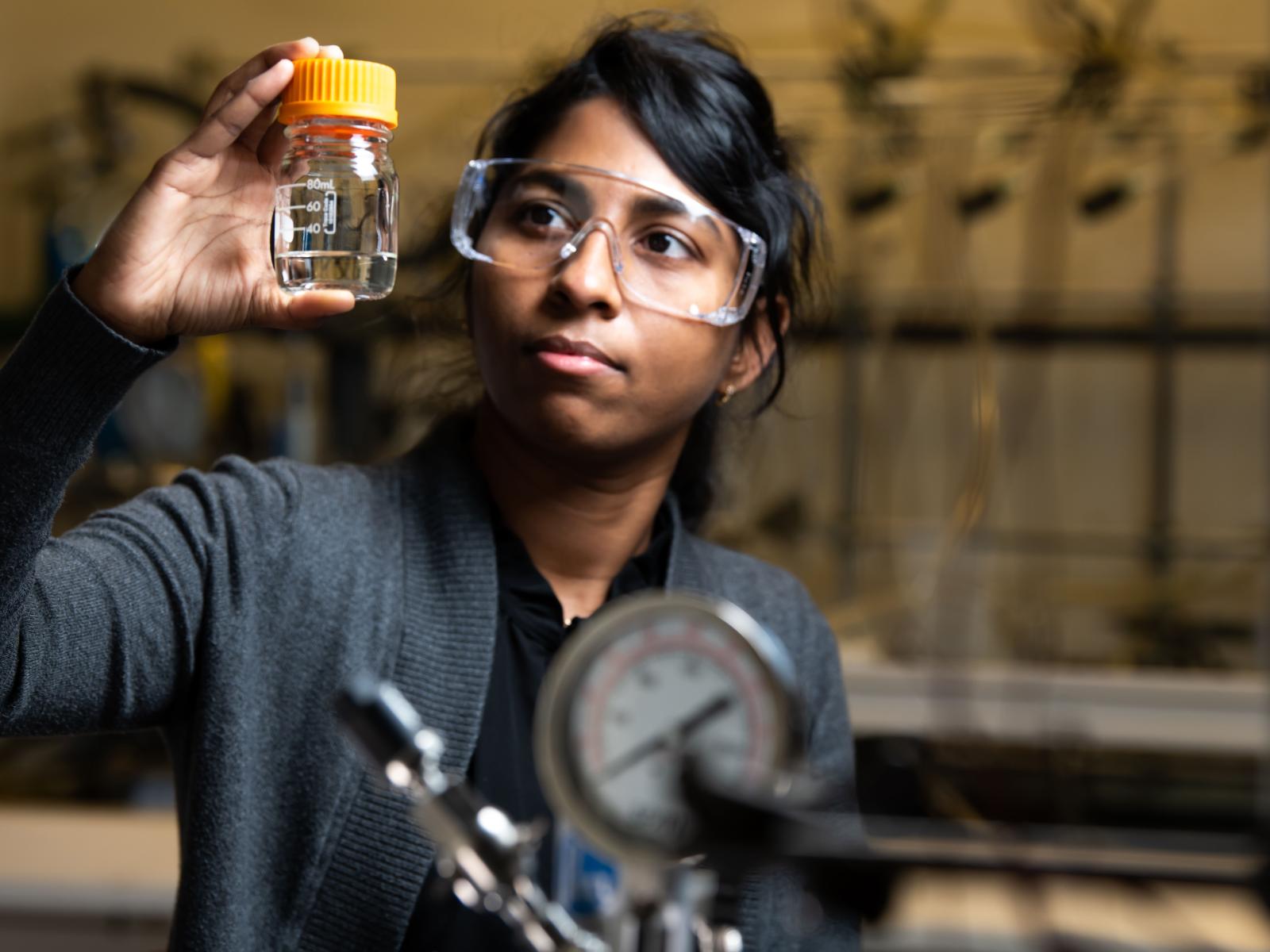

Chemist Jothi Kothandaraman and her colleagues at PNNL designed solvents that can deftly capture carbon dioxide and convert it into methanol, one of the world’s most widely used chemicals.

(Photo by Andrea Starr Pacific Northwest National Laboratory)

Reduce, reuse, recycle. These “three Rs” of sustainability are often associated with Earth Day, celebrated annually on April 22.

When they debuted, they referred to simple actions that citizens could take to help save the planet—like picking up cans along the roadside or turning down their thermostats.

At the Department of Energy’s Pacific Northwest National Laboratory, researchers apply their expertise to the three Rs as they explore novel clean energy technologies that will help meet national goals to achieve net-zero greenhouse gas emissions by 2050.

For example, PNNL’s scientific research, technical analysis and stakeholder engagement support DOE’s efforts to reduce energy consumption in commercial buildings, which are responsible for 35% of the nation’s electricity consumption.

As part of decarbonization efforts, our experts assist DOE in developing energy codes and design guides for new commercial buildings. They also inform performance standards for existing commercial buildings.

To help evaluate energy efficient devices and bring them to market, researchers use two side-by-side environmental chambers purchased by the Washington State Department of Commerce to measure the performance of heating, ventilation and air-conditioning systems.

The chambers provide controlled temperature and humidity, with one representing interior conditions while the other simulates outdoor conditions.

They also are exploring how various types of equipment can be used to dynamically flex energy consumption to balance supply and demand.

In other research, our data scientists are using mathematical models of a building to predict its behavior.

Those predictions enable optimal control actions that consider not only efficiency, but also occupant comfort, weather forecasts and other factors.

PNNL’s contributions to the other two Rs, reuse and recycle, focus on opportunities to shrink industry’s carbon footprint. In one effort, our researchers are making it easier and cheaper to convert plastics that often end up in landfills into fuel.

The scientists developed a new catalyst that replaces a two-step, high-temperature process with a single-step process that operates at about room temperature.

By putting PNNL-developed solvents to work, our chemists are making it possible for another traditionally two-step process—capturing CO2 from natural gas or coal plants and converting it to methanol—to be done more cost-effectively in a continuously flowing system.

Earlier this year they used this system to demonstrate the lowest-cost carbon capture technology to date.

In yet another reuse and recycle success, an auto parts manufacturer is commercializing PNNL’s Shear Assisted Processing and Extrusion technology, or ShAPE™, to turn scrap aluminum into high-value components. Energy consumption and carbon emissions during manufacturing can be reduced by more than 90% because mining and refining of raw aluminum is avoided.

In addition to helping others reduce their carbon footprints, we apply similar approaches to our own campuses in Richland and Sequim.

In 2021, PNNL launched its NZERO initiative, short for “Net-Zero Emissions and Energy Resilient Operations.” Our ambitious goal is to eliminate our emissions within 10 years.

At PNNL, heating our buildings is the main source of emissions. We recently received funding from DOE to replace two natural gas furnaces in existing facilities with efficient, electrical systems.

We also are implementing novel systems into new construction, such as using waste heat from our supercomputers to heat nearby buildings.

The second-largest emissions source at PNNL is from the periodic venting of sulfur hexafluoride, a potent greenhouse gas that is used in some of our research equipment.

By contracting with a vendor that recycles this gas rather than venting it, we expect to cut associated emissions by more than half.

While Earth Day reminds us how we can embrace the three Rs in our own actions, the talented scientists, engineers and operations professionals at PNNL are taking innovative approaches to the three Rs that will make the world a better place for our children—not just on Earth Day, but every day!

Steven Ashby, director of Pacific Northwest National Laboratory, writes this column monthly. To read previous Director's Columns, please visit our Director's Column Archive.

Published: April 21, 2023