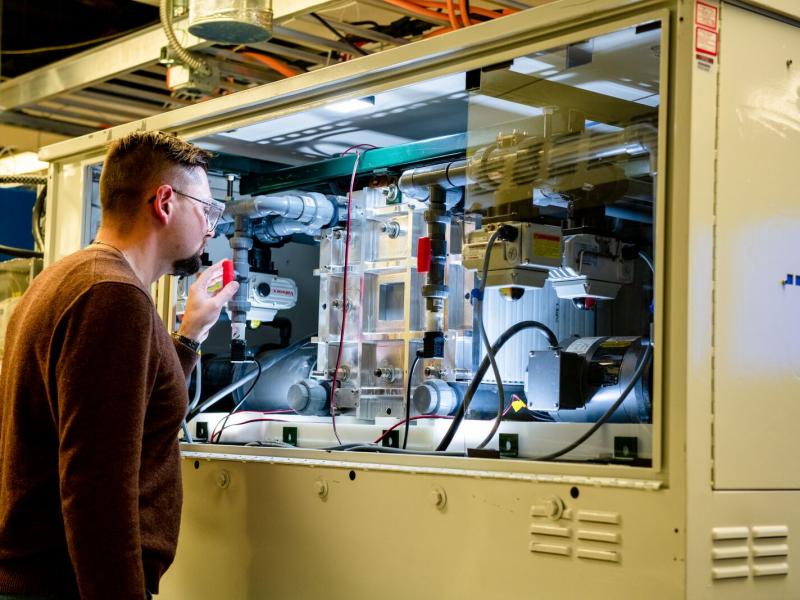

Specialized facilities are essential to the advancement of PNNL’s sponsored research programs and LDRD-funded projects.

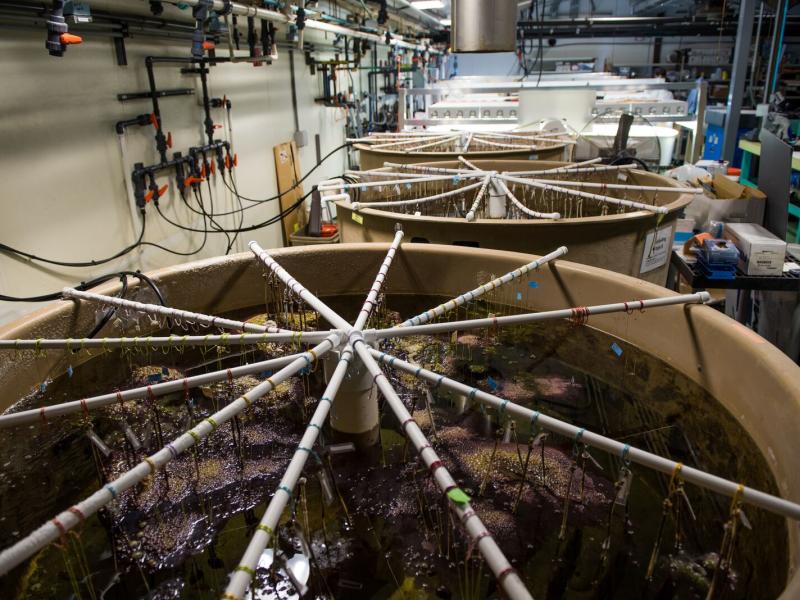

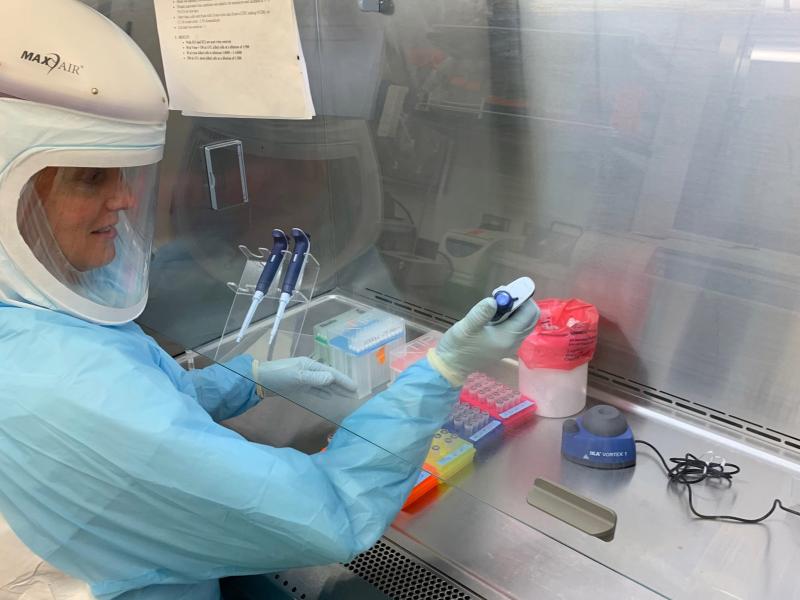

Unique facilities at PNNL, including dedicated laboratories for power grid operations, marine sciences, data analytics, and atmospheric sciences, equip researchers to take on some of the most challenging questions, and expand the frontiers of scientific understanding and technological possibility.

In addition to more than two dozen state-of-the-art facilities supporting the laboratory’s missions in scientific discovery, energy resiliency, and national security, PNNL is the steward of two U.S. Department of Energy national scientific user facilities, ARM and EMSL, serving more than 2,000 researchers worldwide each year.

77 results found