PNNL and Ampcera to Commercialize All-Solid-State Battery Materials

The collaboration supports U.S. priorities related to domestic supply of electrolyte materials as well as research for safe, durable, and high-performing batteries

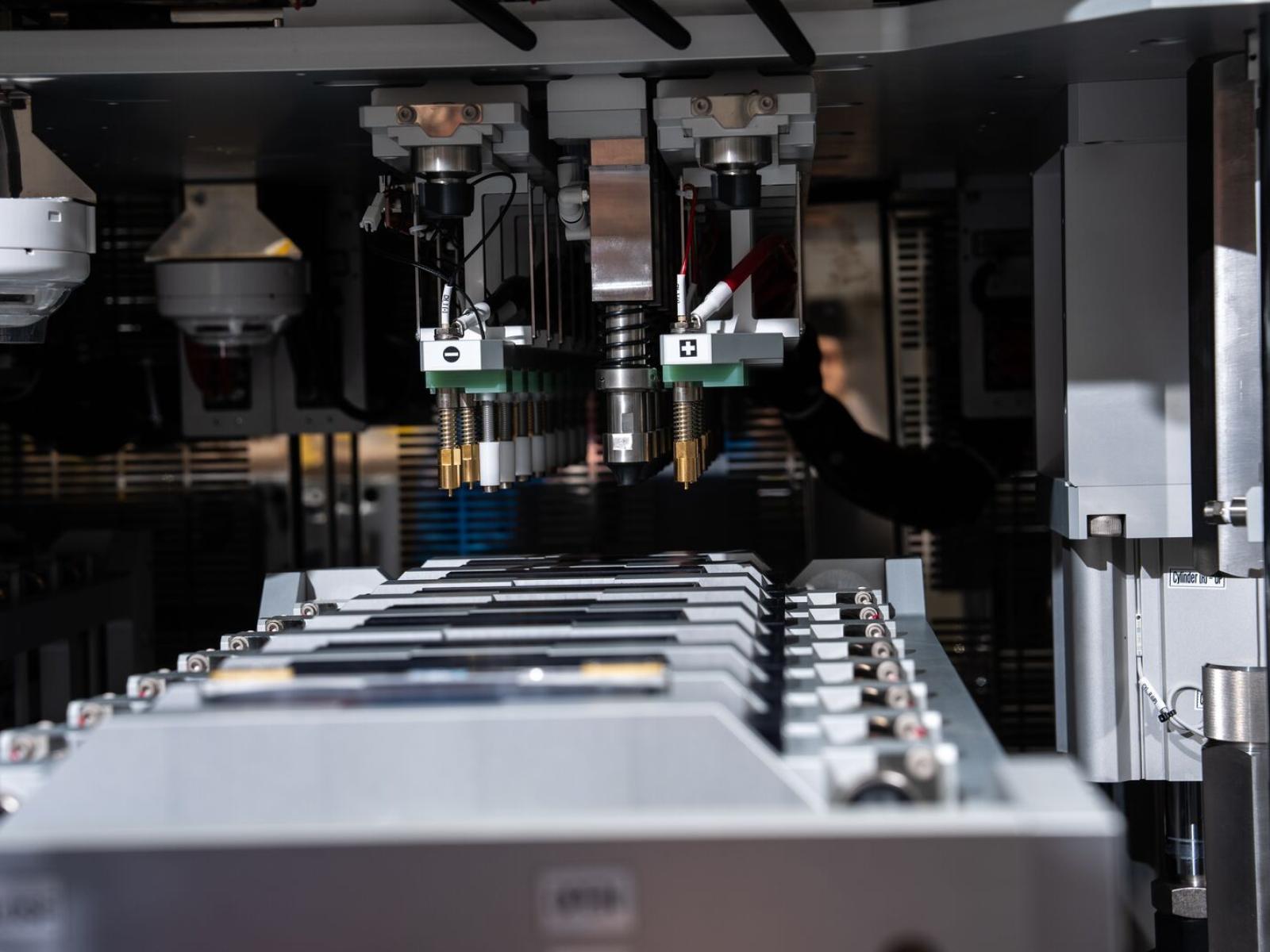

Ampcera has an exclusive licensing agreement with Pacific Northwest National Laboratory to commercially develop and license a new battery material, like those shown here, researched for applications such as vehicles and personal electronics.

(Photo by Andrea Starr | Pacific Northwest National Laboratory)

Researchers at the U.S. Department of Energy’s Pacific Northwest National Laboratory (PNNL) are partnering with U.S. materials company Ampcera, Inc., to help bring a new solid-state battery technology to the market.

The PNNL-developed technology introduces a new solid-state electrolyte technology and air-sensitivity protection strategy that has the potential to enhance performance and reduce manufacturing costs.

Researchers at PNNL originally developed a core solid electrolyte material that was shown in laboratory studies to improve the performance of all-solid-state lithium batteries (ASSBs). The electrolyte technology creates a robust solid interface when in contact with lithium or silicon anodes. Research shows that the solid interface can improve lithium cycling stability to last upward of thousands of hours and can improve overall lithium full-cell performance by enhancing adhesion and ion transport, even at high currents and temperatures (Ref. ACS Nano 2024, 18, 11955-11963). So far, the research team has created prototype ASSB pouch cells with silicon as an anode, engineered by Ampcera. The team reported that the prototype remained stable over 6,000 cycles.

PNNL and Ampcera have entered into an exclusive option agreement to encourage development of the technology.

“Ampcera is proud to join forces with PNNL,” said Sumin Zhu, cofounder and chief executive officer of Ampcera. “Together, we can develop a promising solid-state battery technology aimed at achieving significant charging, safety, and reliability advantages.”

Over the next year, PNNL and Ampcera will work to further optimize the material and scale up the manufacturing process.

“PNNL develops new ideas and technologies to transition scientific knowledge to the market in order to address challenges in energy efficiency, grid resilience, and national security,” said Allan Tuan, senior commercialization manager at PNNL. “Improving the performance and stability of solid-state lithium batteries, while supporting domestic supply, complements our vision of market innovation for enhanced energy security and U.S. manufacturing.”

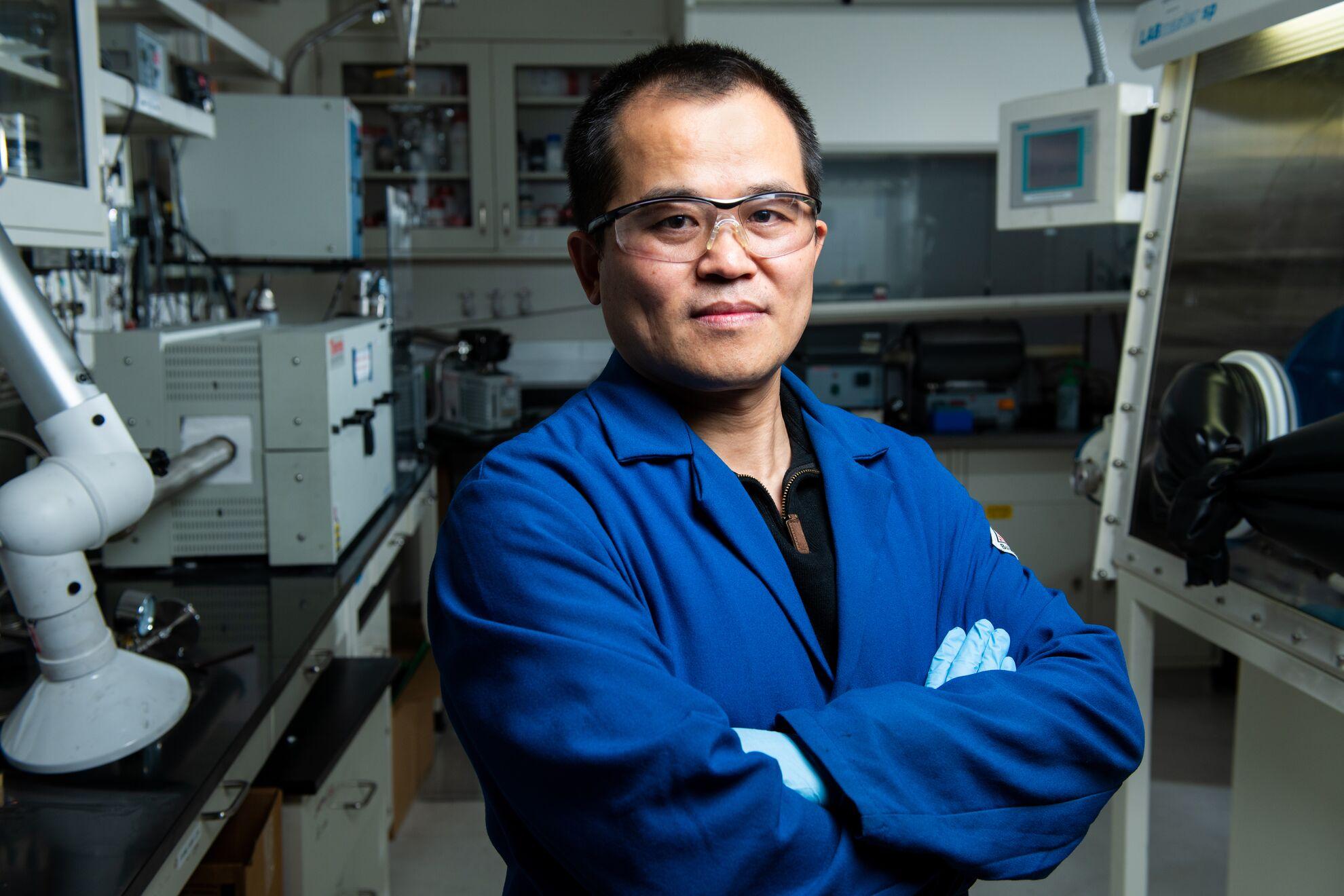

PNNL seeks to understand and tackle ever-increasing energy storage challenges head-on. “A strong commitment to fundamental research is crucial to innovation that addresses scientific challenges with solid-state batteries,” noted Dongping Lu, a materials scientist at PNNL and leader of the Battery Materials Research team. “Equally important are commercialization partnerships following our R&D that aim to enhance the U.S. supply chain and ensure that these advancements are swiftly brought to market where they are needed most.”

Ampcera develops solid-state electrolyte materials and scalable manufacturing processes for next-generation solid-state batteries. The company is headquartered in Milpitas, California, with research and manufacturing facilities in Tucson, Arizona.

Battelle, the managing and operating contractor for PNNL, has filed multiple patent applications associated with the technology. The technology was developed with support from the Department of Energy’s Vehicle Technologies Office and Advanced Materials and Manufacturing Technologies Office.

Published: May 23, 2025