Safe Solutions for the Future of Groundwater Cleanup

PNNL chemists investigate the performance of ion exchange resins for subsurface remediation of uranium, technetium, and chromium

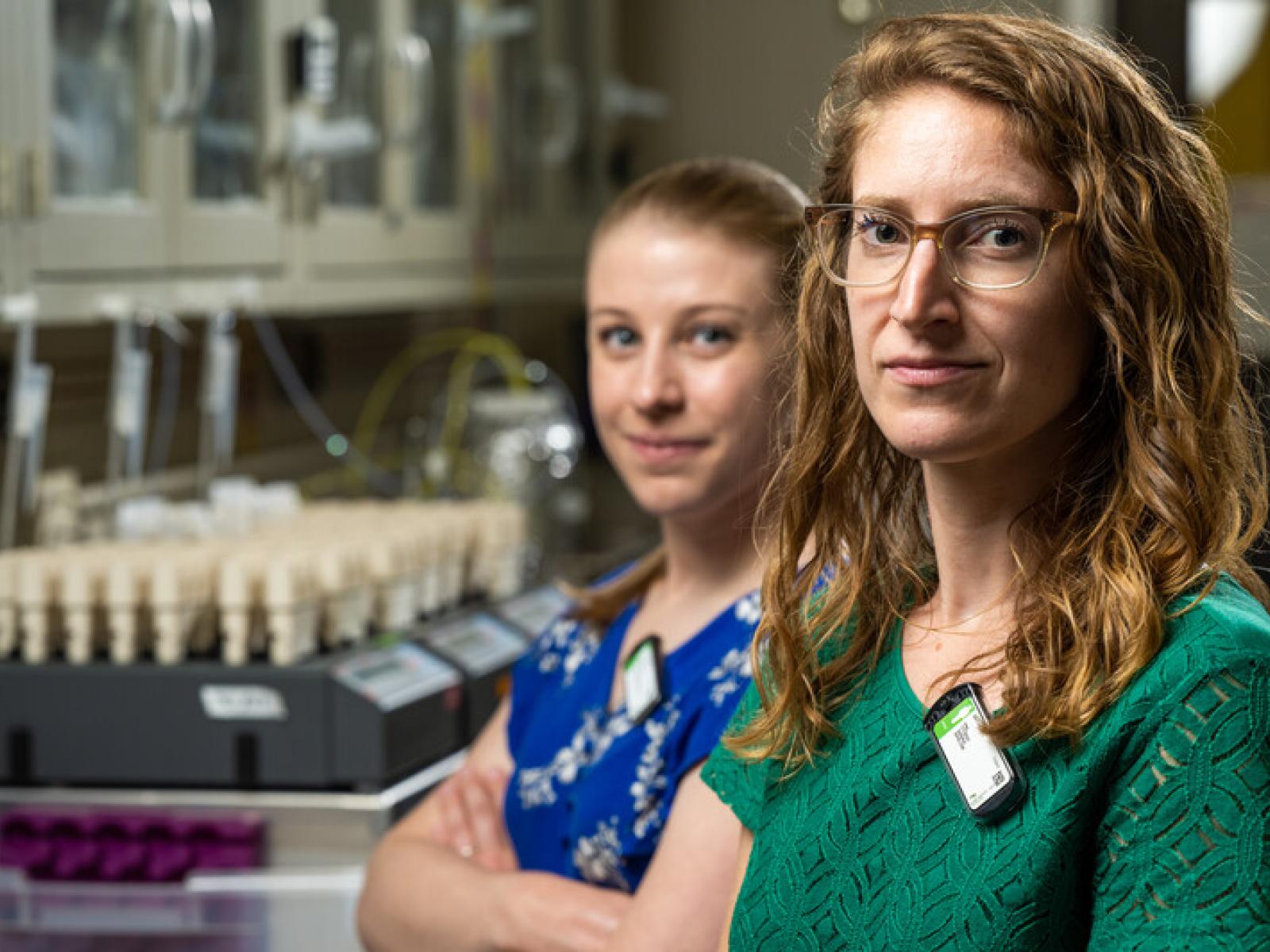

PNNL chemist Sarah Saslow and Earth scientist Jackie Hager conduct experiments that investigate the performance of ion exchange resins for groundwater remediation at the Hanford Site.

(Photo by Andrea Starr | Pacific Northwest National Laboratory)

A cleanup priority for the Hanford Site in Washington state is removing Cold War-era chemical and radiological contaminants from the groundwater.

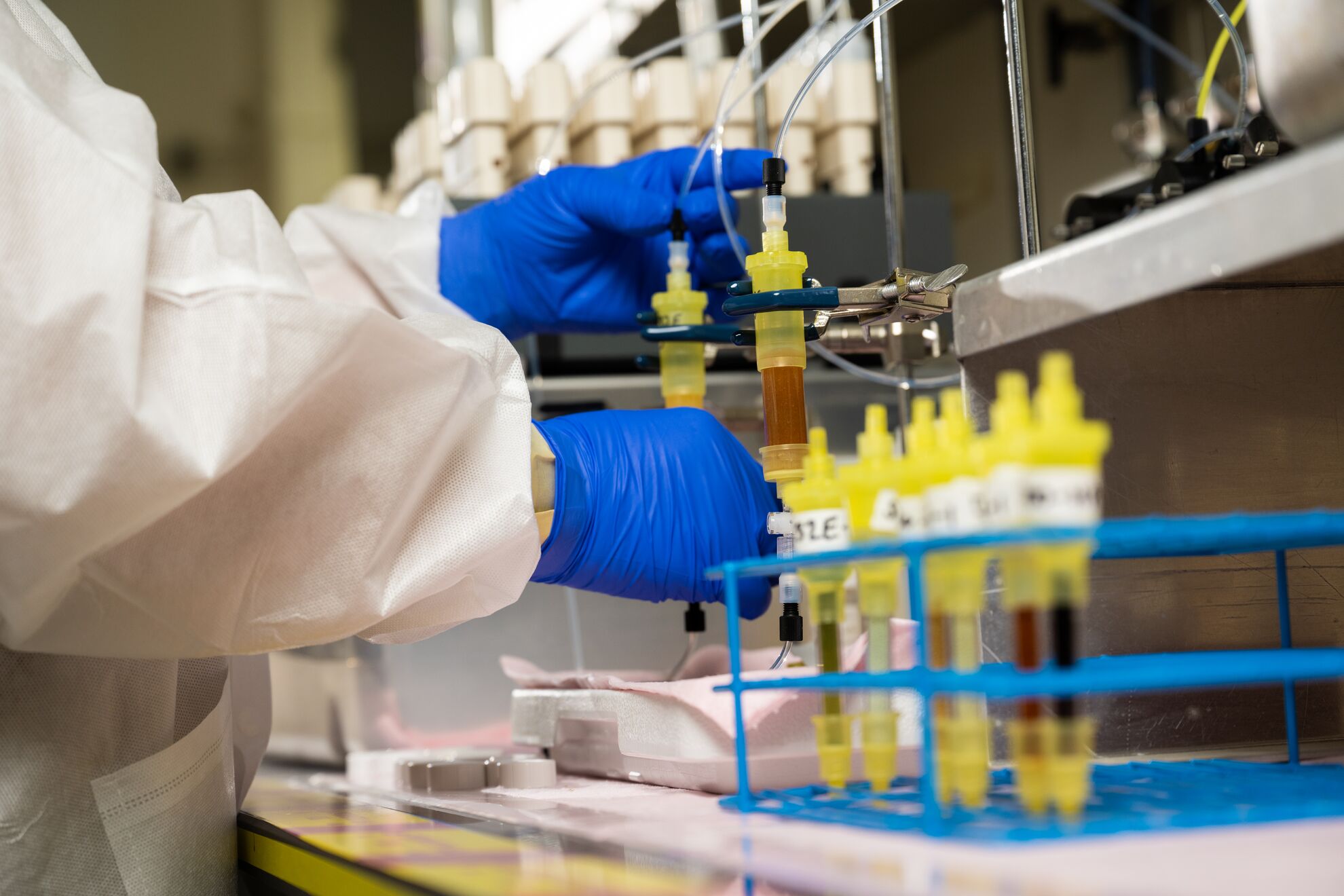

Currently, the Hanford Site uses pump-and-treat facilities to contain contaminated groundwater plumes and prevent them from reaching the Columbia River. The pump-and-treat process extracts the groundwater and treats it to remove contaminants. The treated water then is returned to the subsurface. One of these facilities is the 200 West (200W) pump-and-treat facility, located in the Central Plateau, also known as the 200 Area, of the Hanford Site. The 200W pump-and-treat facility can treat up to 2,500 gallons of contaminated groundwater per minute by using a combination of water treatment technologies, including ion exchange (IX) resins.

Though much more complex, the IX treatment process works like the water filters commonly used in homes across the United States, or refrigerators with water dispensers. Water passes through a filter containing solid materials, like IX resins. The IX resins remove contaminants as the water passes through the treatment system. Just as the IX resins in the water filters at home are designed to capture chemicals like zinc and copper, the IX resins used at the 200W pump-and-treat facility can treat contaminants like uranium and technetium.

IX resins can be designed to target specific contaminants based on properties like contaminant size, charge, and hydration energy. PNNL chemists Sarah Saslow, Carolyn Pearce, and Tatiana Levitskaia led a team as part of the Deep Vadose Zone project, funded by the Department of Energy Office of Environmental Management’s Richland Operations Office. The team evaluated two IX resins currently used for groundwater remediation—Purolite A532E for technetium removal and DOWEX 21K for uranium removal—to inform the planning process for the optimization and expansion of the remedy.

Part I and Part II of the two-part study—published in the Journal of Environmental Chemical Engineering—explored the impact of operation growth and expansion of the extraction well network on the performance of Purolite A532E and DOWEX 21K.

“The Department is always seeking more safe, efficient, and cost-effective ways to improve the performance of the groundwater treatment network, with protection of the Columbia River as the goal,” said Naomi Jaschke, Director of DOE Hanford’s Soil and Groundwater Division.

The PNNL research team incrementally introduced competing groundwater contaminants and common ions, like sulfate, nitrate, carbonate, and chloride, at various concentrations to evaluate the performance of the IX resins. The tests were designed based on groundwater chemistry determined from site monitoring efforts at Hanford.

“Additional extraction wells that tap into different areas of the site might have different groundwater chemistries that could introduce fluctuating concentrations of naturally occurring ions or other common groundwater constituents that could affect ion exchange performance,” said Saslow. “It was proposed that sulfate could be a competitor for uranium and reduce the lifecycle and effectiveness of DOWEX 21K, and nitrate would compete with technetium and do the same for Purolite A532E.”

The case studies demonstrated that even with high concentrations of other ions in groundwater, the IX resins at the 200W pump-and-treat facility will successfully remove the contaminants to levels below the regulated maximum contaminant requirements.

Saslow, Pearce, and Levitskaia are currently expanding their research with column studies to test if kinetics, the speed at which the groundwater passes over the resin, impacts the interactions of competing contaminants with IX resins. The team is also discovering new technologies, like hybrid resins, for treating additional contaminants like chromium and iodine that may be present when new extraction wells are built.

Hybrid resins have the potential to remove technetium, uranium, chromium, and iodine contaminants selectively. Rather than using four different resins, one hybrid resin or hybrid resin pairs could work together to target and then remove contaminants. They offer possible alternative solutions to costly facility alterations that would be needed to accommodate additional IX resins that address chromium and iodine.

“It’s exciting to work on cleaning up the Hanford Site,” said Pearce. “Our experiments in the lab inform the performance of the resins that are currently in use. The work allows us to predict their behavior and help inform future operations as the cleanup mission expands.”

PNNL is collaborating with the Central Plateau Cleanup Company to identify implementation pathways for the research.

Published: September 12, 2023