Machine Learning Provides Chemistry of Uranium Insight for Advanced Reactors

Pacific Northwest National Laboratory researchers use chemometric analysis to model chemistry in molten salt

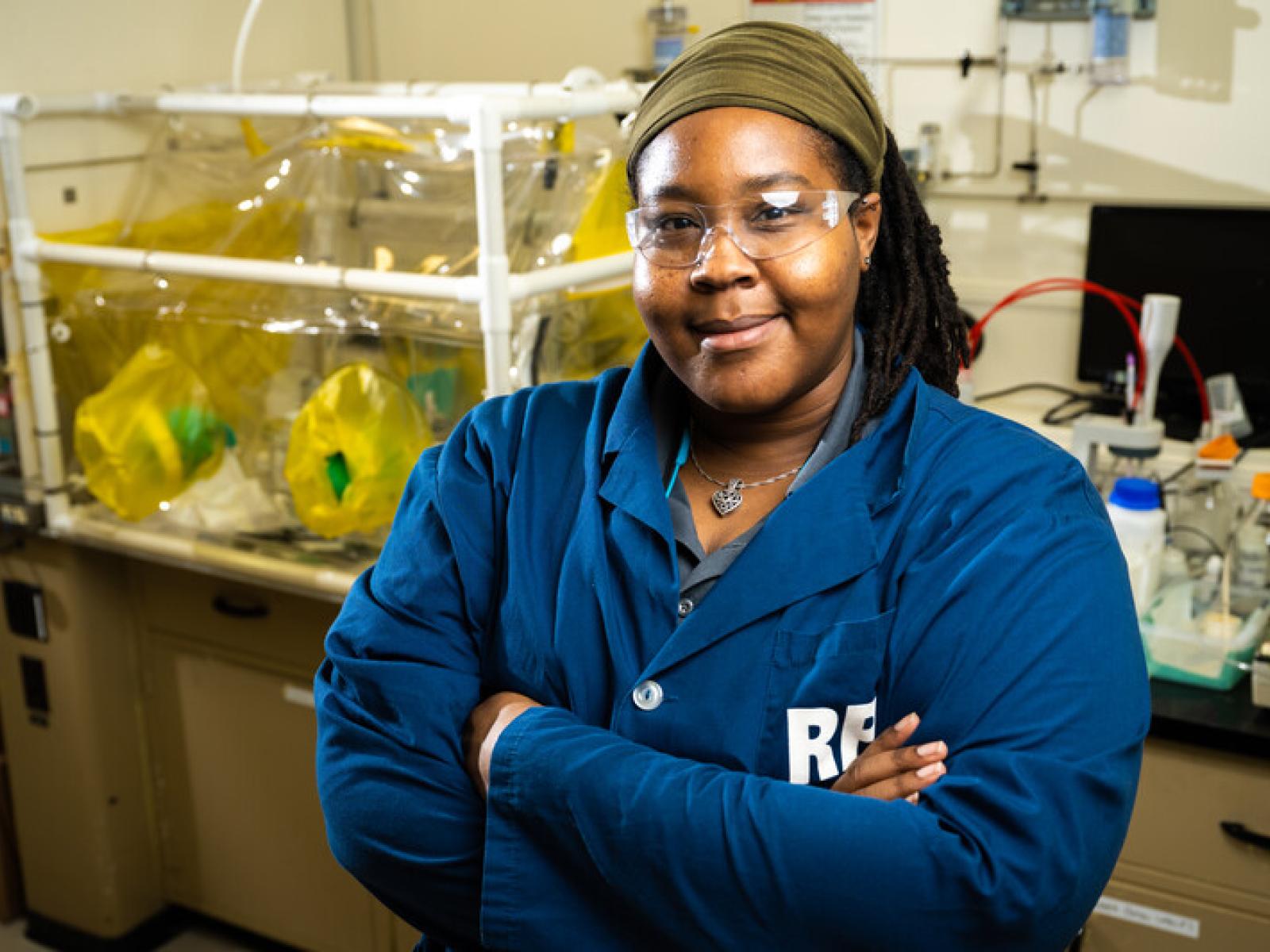

PNNL is evaluating the chemical behavior of molten salt systems for potential use in nuclear power reactors for the DOE Office of Nuclear Energy’s Advanced Reactor Safeguards and Security (ARSS) program. Nuclear chemists like Shirmir Branch use glove boxes in the Radiochemical Processing Laboratory to prepare different combinations of chloride-based salt samples—including sodium-, potassium-, magnesium-, and lithium-based chloride—for spectroscopy and electrochemistry analysis.

(Photo by Andrea Starr | Pacific Northwest National Laboratory)

Uranium fuel dissolved in salt that is heated above its melting point is one design for a molten salt reactor (MSR), an advanced reactor concept for clean energy generation. How will nuclear power plant operators know what is happening within that extreme environment? How will they know if everything is running as expected?

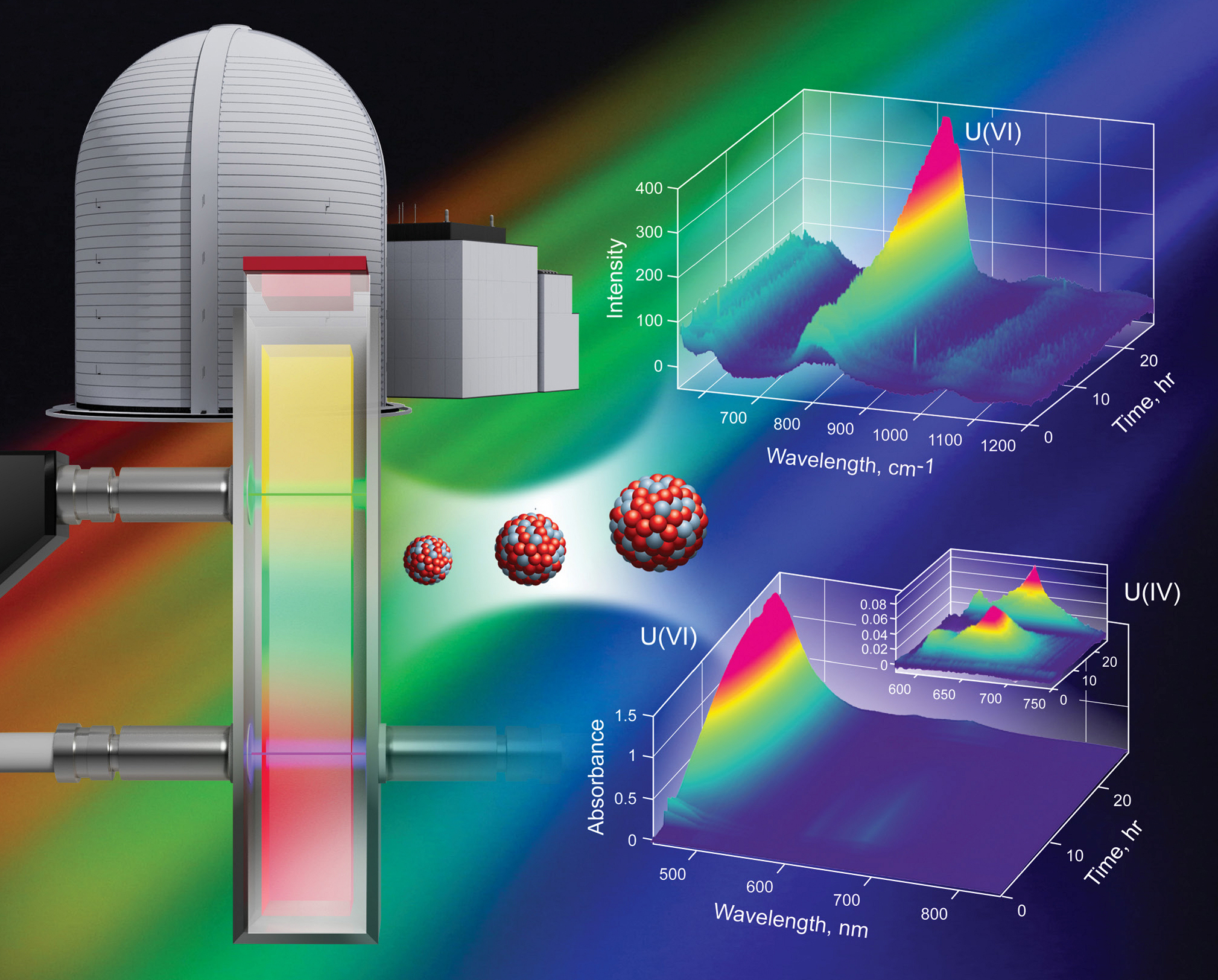

Pacific Northwest National Laboratory (PNNL) researchers have developed sensors and a technique for real-time on-line monitoring of the uranium chemistry inside MSRs. The latest research, led by Chemist Shirmir Branch, was featured on the cover of the American Chemical Society’s Industrial & Engineering Chemistry Research journal.

“We are working with general hardware like spectrometers or electrical analyzers to place inside of harsh environments, where it would be risky or expensive to have a person there physically taking measurements,” said Branch. “With sensors throughout the system, we can get a snapshot of the chemistry happening within.”

The sensors collect data for chemometric analysis, which can be used to automate the translation of raw data into usable information. This information equips engineers and operators with details that enable proper reactor operation and help limit corrosion or interaction of molten salt with reactor materials. It also provides insight for species inventory, or the chemical makeup of all substances in a reactor. Work published in the recent article is particularly aimed at providing tools for material control and accounting, allowing appropriate safeguarding and tracking of nuclear material.

The PNNL researchers use what is called optical spectroscopy.

“We're essentially shining light at a sample and looking at how that light interacts with the sample; things like uranium and plutonium will have unique fingerprints,” said PNNL Chemist Amanda Lines. “Chemometrics is a form of chemical data science, or if you're looking for a more general term, it's a type of machine learning, which extracts those fingerprints from complex data.”

MSRs are highly complex chemical systems. The challenge is parsing the data collected. The individual fingerprints of the numerous chemical species present in a sample can overlap or interfere with one another.

"Let's say I have a complex solution of uranium, plutonium, and a bunch of other chemicals,” Lines said. “I can pull out the optical fingerprint of uranium from the overlapping fingerprints of all chemicals present and then use that fingerprint to quantify the uranium present."

The chemometric model was built to specifically find and quantify the uranium within the molten salt, but it can be used for a wide range of other chemical species in complex systems.

The technology has been tested with small-scale furnace systems that mimic some of the extreme environmental conditions of an MSR.

“It makes it easy for a reactor operator to see what's going on within the reactor itself and make changes accordingly in real time,” Branch said.

Lines added, “These chemometric analysis tools that we’re developing have many more uses beyond supporting operators. The on-line monitoring tools are invaluable when you're talking about researchers and engineers who are trying to design a new process as well as scale up that process. They can open brand new doors of opportunities around fundamental system characterization.”

MSRs are an active area of research and development as the nuclear energy industry looks for advanced reactor designs that have smaller footprints and more efficient operations. Recently, the Nuclear Regulatory Commission approved the construction permit for the first MSR test reactor in the United States.

Nuclear energy provides nearly 20 percent of the nation’s electrical demand and is the largest source of carbon-free energy on the current electric grid.

Published: February 16, 2024