Technical Specifications

Collecting a comprehensive set of atmospheric and oceanographic measurements needed for offshore wind resource characterization.

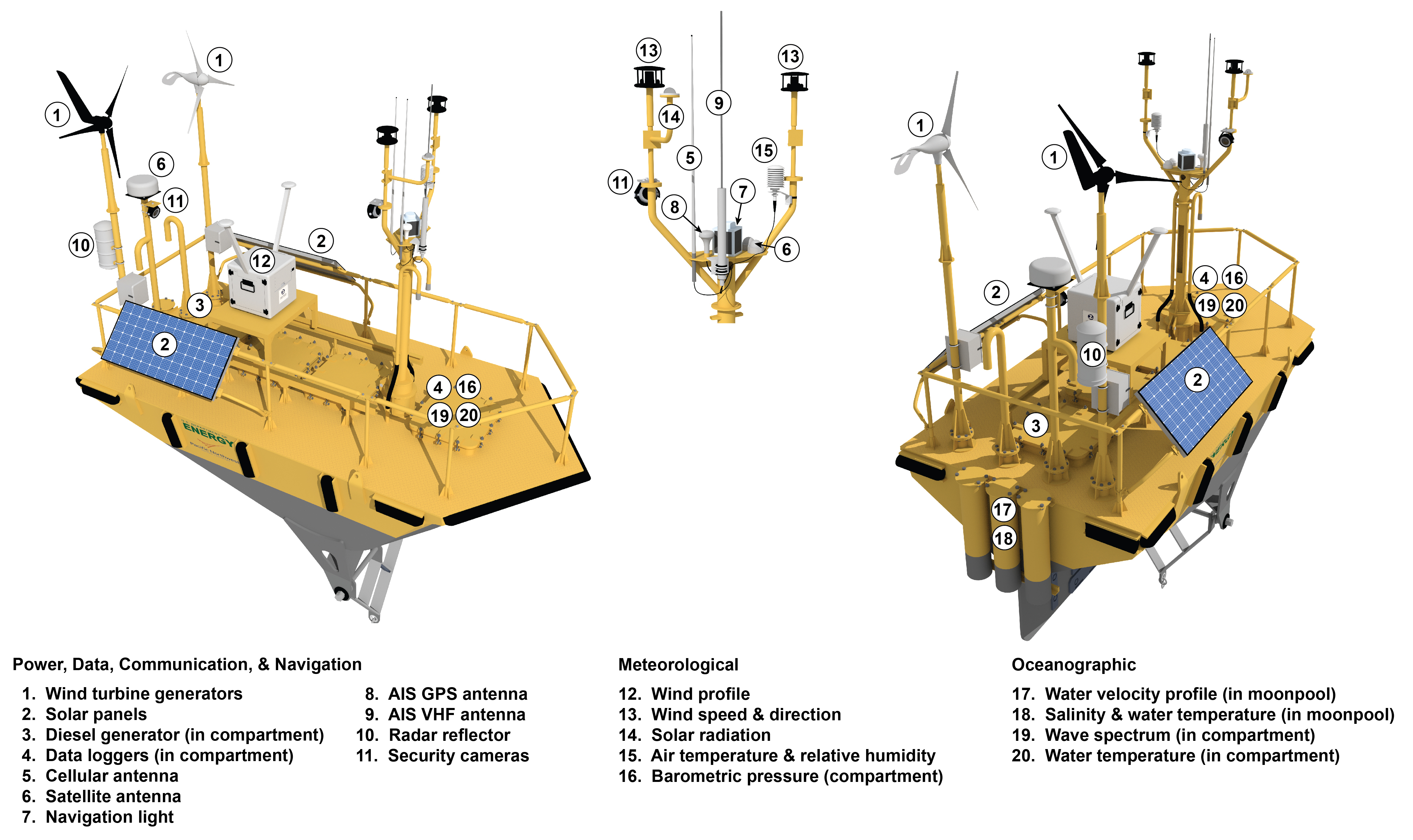

The WindSentinelTM lidar buoys, manufactured by AXYS Technologies, collect a comprehensive set of atmospheric and oceanographic measurements needed for offshore wind resource characterization. The centerpiece of the instrumentation suite for each buoy is a motion-corrected lidar system that can provide profiles of the wind speed and direction up to 250 meters above the sea surface. In addition to a lidar, each buoy collects complementary oceanographic and near-surface meteorological data. Meteorological and oceanographic instruments on the two buoys are identical and are described in the figure and table below:

| SENSOR TYPE | MANUFACTURER | MODEL | ITEM # IN CONFIGURATION |

|---|---|---|---|

| Wind profiling lidar | Leosphere | Windcube 866 | 11 |

| Cup anemometer | Vector Instruments | A100R | 12 |

| Wind vane | Vector Instruments | WP200 | 13 |

| Ultrasonic anemometer | Gill | Windsonic | 14 |

| Pyranometer | Licor | LI-200 | 15 |

| Temperature, relative humidity | Rotronic | MP101A | 16 |

| Barometer | RM Young | 61302V | 17 |

| Acoustic Doppler Current Profiler (ADCP) | Nortek | Signature 250 | 18 |

| Conductivity, Temperature Depth (CTD) | Seabird | SBE 37SMP-1j-2-3c | 19 |

| Directional wave sensor | AXYS | TRIAXYS NW III | 20 |

| Water temperature | AXYS | YSI | 21 |

| Tilt/compass | Microstrain | 3DM GX3 25 | NA |

| Tilt/compass | Microstrain | 3DM GX5 45 | NA |

Data Acquisition System

The data acquisition system provides flexibility for user definition and control of averaging intervals for all instrumentation. In general, observations can be recorded at the highest rate available for each instrument to allow maximum flexibility in subsequent analyses. In most cases, this is a sampling rate of once per second.

Data collection on each buoy is managed by an industrial personal computer that integrates data collected from the two AXYS Watchman500 data loggers, Campbell Scientific data logger, and Windcube lidar. Raw data and 10-minute averaged data are stored on compact flash cards onboard the Watchman500 and Campbell Scientific data loggers. The subset of the data are transferred to shore via cellular (high-bandwidth) communications when close to shore or satellite (low-bandwidth) communications. Complete data recovery requires physically exchanging the compact flash card during regular maintenance visits to the buoy. Each lidar buoy has extensive documentation of all of its systems, including instrumentation, power, data collection, communications, and safety.

Data from the buoys are reported online through the Data Archive and Portal as described on the Data Access section of this webpage.

Lidar Validation

Verifying the readings from the lidar buoys before each deployment helps evaluate the accuracy and uncertainty of the subsequent wind resource measurements. Guidelines for validating the performance of floating lidar systems are described in two documents published by the Carbon Trust, including their Roadmap for Commercial Acceptance of Floating Lidar Technology and a set of Recommended Practices for Floating Lidar Systems, which was later published by the International Energy Agency Wind Technology Collaboration Programme.

The validation process involves deploying each lidar buoy near a trusted reference source for comparison. The lidar must collect measurements across a range of wind conditions, including low- and high-wind speeds, that can be evaluated against the reference source. A typical validation process can take between four and eight weeks in order to capture enough measurements across the required wind speed range.

After upgrading the buoys with Leosphere Windcube-866 lidars to improve measurement accuracy at the upper elevation ranges, both lidars were independently validated before being deployed off the California coast.

More Information

Validation reports for each buoy are provided below, with permission from DNV. The lidar buoy program is funded by DOE's Wind Energy Technologies Office. The buoys are owned by DOE and managed by PNNL as part of PNNL's wind energy portfolio.