Research and Programs

Our core program

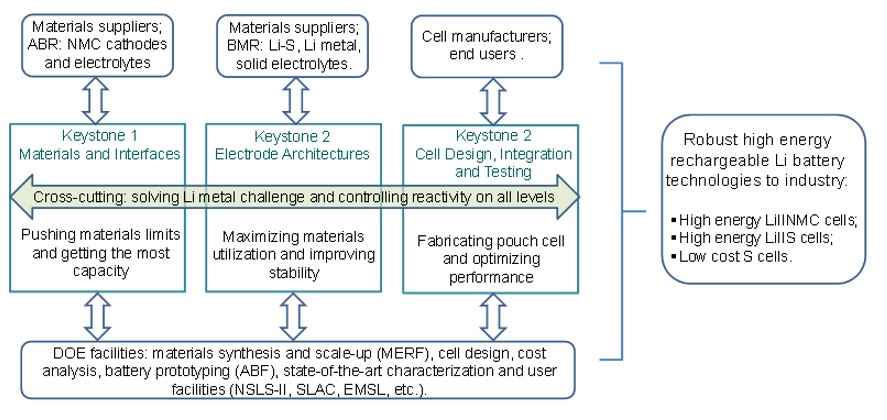

The Battery500 Consortium takes advantage of the multidisciplinary capabilities in materials science, materials chemistry, electrochemistry, battery chemistry, and battery systems as well as cell design, manufacturing, testing, state-of-the-art characterization, modeling, and diagnosis. The consortium works to rapidly integrate fundamental research with realistic cell design, manufacturing, and validation; fully use the capabilities of partner national laboratories and universities; collaborate with other DOE-funded projects; and work closely with U.S. industry partners.

The consortium selects the most promising and feasible battery chemistries to achieve high energy performance and addresses challenges for using these advanced materials in high-energy pouch cells as well as other material challenges and requirements in the design, fabrication, and testing of high-energy cells.

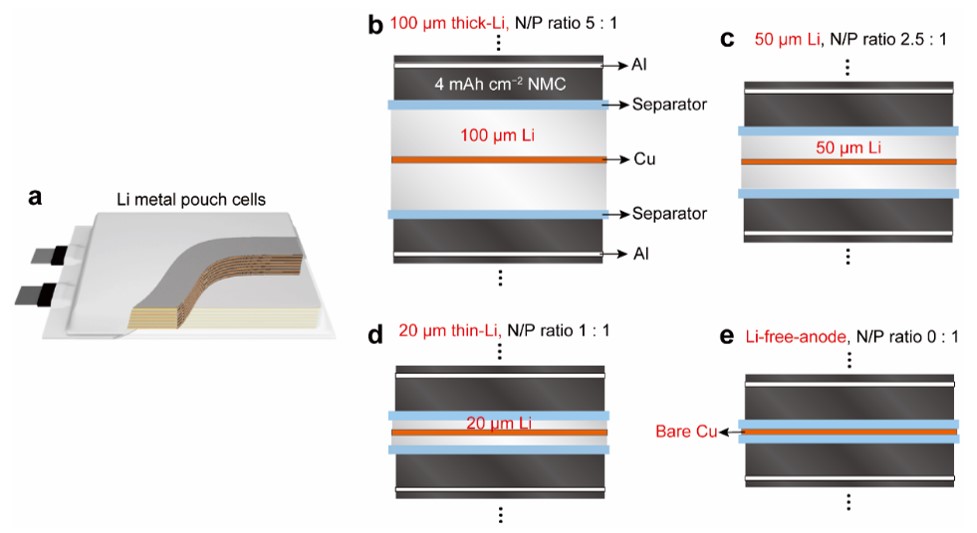

A key emphasis is on developing the fundamental principles for high-efficiency Li deposition and ultra-thin Li-metal anodes at the cell level. The consortium develops high-energy design principles to meet the requirements of realistic high-energy cells. These requirements are used to guide the consortium’s roadmap and deliverables and to make sure that all research efforts are aligned with consortium goals.

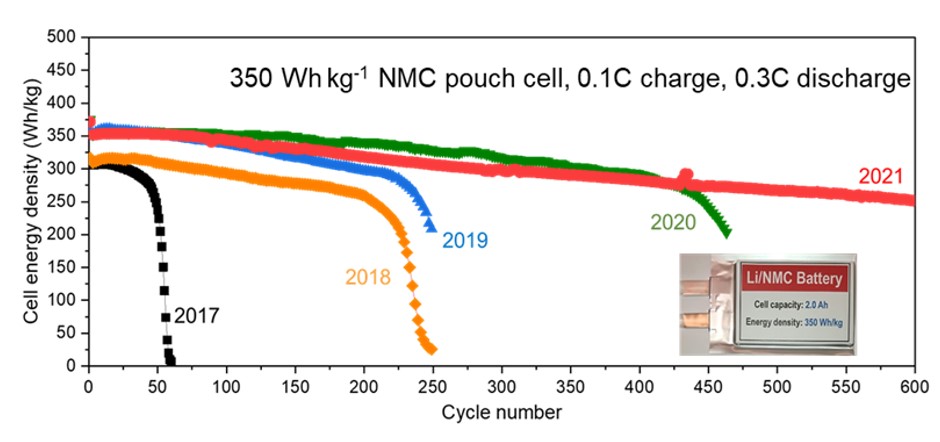

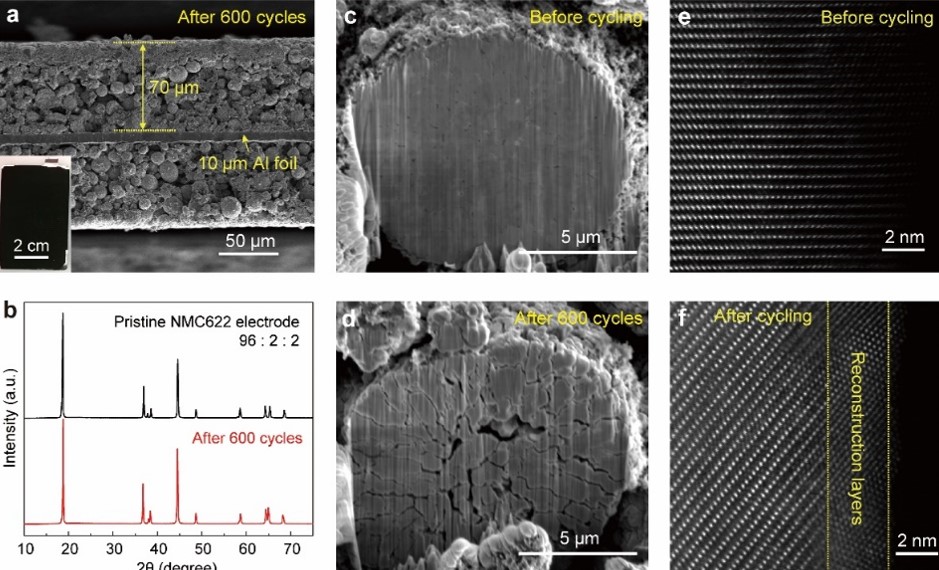

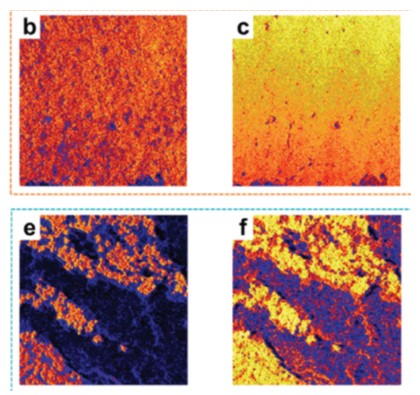

The consortium focuses on key scientific challenges to push the limits and use of the materials to achieve high-energy density and enable exceptionally high-efficiency Li-metal anodes, high nickel content NMC, and sulfur cathodes, as well as gain total control of system-level electrochemical processes for long cycling and robust performance.

The consortium also deploys systematic approaches and standard protocols to rapidly test and validate new materials and concepts, from coin cells to pouch cell levels using realistic conditions required for demonstrating high-energy cells with high performance.

Our thrust areas

Keystone Project 1 – Materials and Interfaces

The goal is to develop strategies to achieve, stabilize, and use the maximum intrinsic capacity of the latest electrode materials. This keystone project aims to push the limit of the electrode materials to achieve and use their highest capacity and energy

Keystone Project 2 – Electrode Architectures

The goal is to enable high use of active materials while reducing the parasitic weight of the inactive materials. This keystone project focuses on the design and fabrication of stable cathode architectures to achieve high electrode loading and maximize use of the active materials to obtain high cell-level energy density.

Keystone Project 3 – Cell Design, Fabrication, and Integration

The goal is to integrate the latest results from Keystone Projects 1 and 2 to fabricate and demonstrate the performance of high-energy cells. This keystone project develops design principles of high-energy cells, capabilities, and strategies to fabricate such cells, and develop and use systematic approaches to test and validate performance of high-energy cells.

Cross-Cutting Project

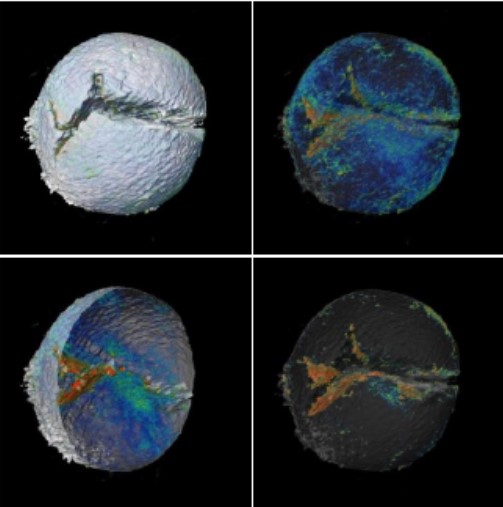

The goal is to provide a quantitative and quantitative understanding of materials and cell degradation mechanisms under realistic conditions in order to achieve long cycle life and robust performance.

Milestones/Status