Applied Engineering Laboratory

Home of the Smart Advanced Manufacturing program

United States

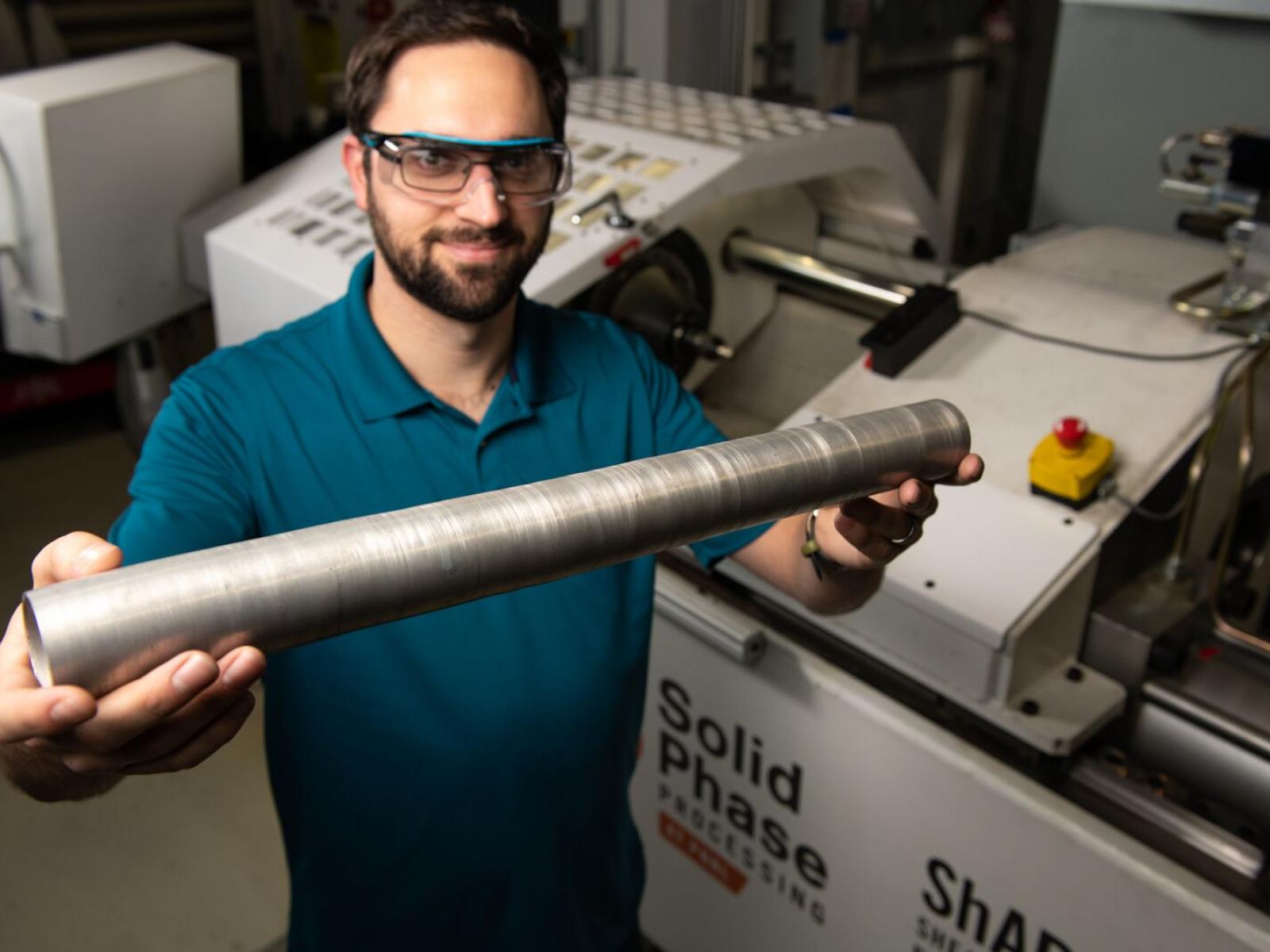

PNNL researcher Brandon Taysom holds a tube extruded by a first-of-a-kind ShAPE machine he helped develop.

(Photo by Andrea Starr | Pacific Northwest National Laboratory)

At the Advanced Engineering Laboratory (AEL), the Smart Advanced Manufacturing (SAM) program at Pacific Northwest National Laboratory is reinventing manufacturing to enable the United States to make higher-performance and more affordable products that advance energy resilience and independence. Many of the SAM techniques involve the use of high shear strain to heat, mix, form, and join metals and other materials without melting them—a powerful approach called solid-phase processing.

SAM’s capabilities at AEL include equipment supporting a range of novel manufacturing approaches, including Shear Assisted Processing and Extrusion (ShAPE), friction stir, and cold spray. This specialized combination of capabilities is leveraged to develop and validate these new manufacturing approaches for applications in various sectors, including automotive manufacturing, industrial processes, nuclear power, electricity generation, construction, oil and gas exploration, aerospace, and national security.

AEL houses a wide range of machines and testing environments. These are some of the technologies pursued by the SAM program in AEL:

- Shear Assisted Processing and Extrusion (ShAPE) – SAM’s flagship technology, the patented, award-winning ShAPE technique, extrudes materials by using a shearing action at the face of the billet to locally heat and plasticize the material before it is pressed through a shaping die. This technique—which is capable of both direct and indirect extrusion—imparts significantly more deformation into the material than does conventional extrusion, offering a number of unique advantages.

- Friction Stir – Friction stir techniques involve the use of a spinning tool to generate intense levels of deformation and heat. They can be used for joining, local processing, and additive manufacturing. Friction stir welding requires a small fraction of the energy of conventional fusion welding, dramatically reducing costs. Friction stir techniques can join dissimilar materials that cannot be joined by other methods, enabling the production of next-generation products.

- Cold Spray – This is a solid-phase metal deposition process used for coating or additive manufacturing that can deliver superior material properties. During cold spray, powder is injected into a heated, pressurized carrier gas stream and accelerated to supersonic speeds while exiting a nozzle. Cold spray can be used for repair or improvement—such as increasing a component’s resistance to corrosion.