Toward A Future with Self-Healing Cement

PNNL researchers led a collaborative effort to showcase the most up-to-date, innovative, commercial cement and concrete technologies

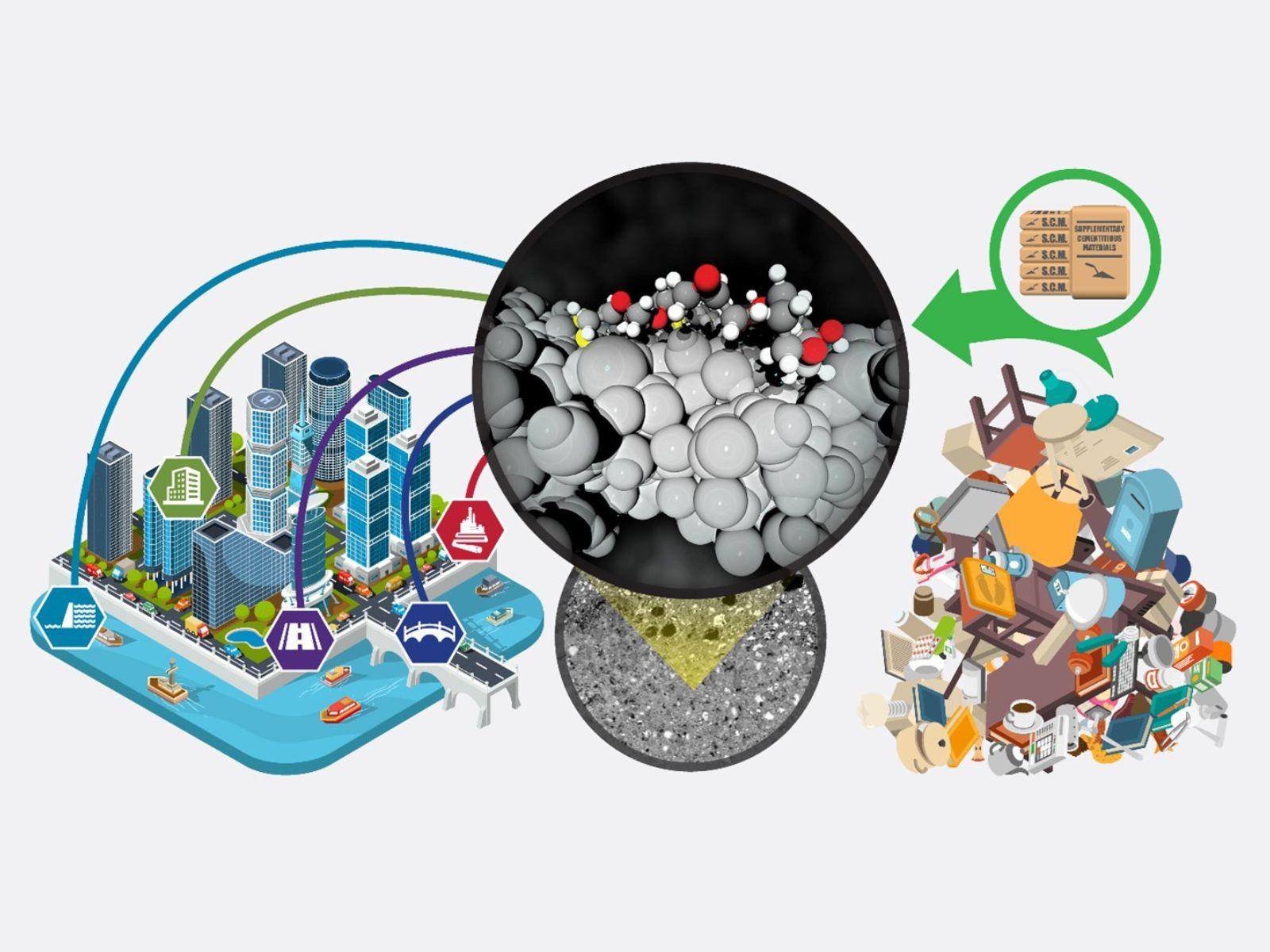

Researchers are looking into ways to use bio-derived and man-made waste as additives in concrete to extend the lifecycle of infrastructure.

(Original graphic: American Chemical Society; Composite image by Cortland Johnson | Pacific Northwest National Laboratory)

Concrete is made from the ingredient cement and is the second most used material worldwide following water. It has been discovered in historical structures built over 12,000 years ago. It is still used today to construct homes, schools, hospitals, bridges, and roads in addition to building energy infrastructure, like geothermal production wells, dams, and nuclear power plants. Although seemingly sturdy, standard concrete has a low tensile strength, making it susceptible to break under tension, crack, and corrode throughout its lifetime.

The concrete industry makes up eight percent of global carbon dioxide emissions. During the production of cement, pollutants like sulfur dioxide, nitrogen oxides, carbon monoxide, and carbon dioxide are emitted. As population and economic growth increase infrastructure construction and as structures built from standard concrete face repair, the concrete industry continues to cause harm to the environment. Creating more durable concrete that exhibits better long-term performance is critical to reducing overall consumption, costly repairs, and carbon emissions.

Current self-healing cement technologies

Pacific Northwest National Laboratory (PNNL) Senior Computational Scientist Manh Thuong Nguyen and Chief Materials Scientist Carlos Fernandez, along with Somayeh Nassiri from the University of California, Davis (UC Davis), were invited to lead a Chemical Reviews Journal article on self-healing cement and concrete technologies. In collaboration with researchers from Oak Ridge National Laboratory, Texas A&M University, and UC Davis, the review explored different molecular approaches to gain insight into the cementitious material performance on a macroscale for deployment to industry.

“The cost of fixing America’s aging infrastructure is about $3 trillion. Advanced building materials like self-healing concrete will play an extremely important role in future construction,” said Nguyen. “But first, we need to understand at a very fundamental level the chemistry and physics of these materials.”

Cementitious self-healing capabilities can be categorized as autogenous and autonomous. Autogenous self-healing capabilities rely on cracked materials healing themselves by using existing materials, such as water and unreacted cement. Autonomous healing is achieved using foreign agents, like bacteria, polymers, and fibers.

The review outlines both forms of self-healing methods and found various ways to enhance or induce each. It found that the durability of autogenous self-healing mechanisms can be improved with additives like fibers and polymers. Polymers add more elasticity to cement when it is added, alleviating strain, and reducing fracture propagation rates.

“Longer-lasting concrete infrastructure requires the capability of autonomous self-healing properties,” said Fernandez. “The combination of experimental and numerical simulations towards the understanding of the mechanism/s responsible for this macroscopic property is key to optimizing the material’s performance towards a specific application.”

Future self-healing cement opportunities

Across the board, research still needs to take place to move self-healing concrete capabilities out of the laboratory and into the infrastructure of today’s modern society. Eventually, the goal is to move it to power sources that are sustaining and modernizing the United States electric grid.

PNNL is one of the organizations at the forefront of this effort. The study reviewed PNNL’s patented self-healing cement technology and the 2020 R&D 100 award-winner which heals itself within 24 hours of a crack occurring, restoring to full strength. The self-healing cement is among the leaders for the technology in performance and cost for deployment.

PNNL’s self-healing cement was designed specifically for high-temperature environments, like those around geothermal and fossil fuel wells. It can reduce or eliminate costly repairs and can extend the lifetime of wellbores by as much as 50 years. Fernandez and team are looking into extending the application of self-healing cement technology towards environmentally friendly solutions for repairing cement cracks and sustaining hydropower dams, transportation infrastructure, or even the commercially-operated nuclear power plants in the United States.

This work was supported by the Office of Energy Efficiency and Renewable Energy’s Geothermal Technologies Office, and the Office of Fossil Energy and Carbon Management at the Department of Energy. Additional authors of the review are Md Mostofa Haider (UC Davis), Kung-Hui Chu (Texas A&M University), Guoqing Jian (Aramco Americas), Difan Zhang (PNNL), Roger Rosseau, and Vassiliki-Alexandra Glezakou (Oak Ridge National Laboratory).

Published: July 7, 2023