Modeling the Movement of Impurities in Molten Uranium

Improving production of actinide metals for national security and energy efforts

Photo by Nordroden | iStock

The bottom row of the periodic table contains 15 elements, numbered 89 to 103, called the actinide metals. They are used in a variety of ways, from producing nuclear energy to making sure pacemakers and smoke detectors work correctly.

One of the most naturally abundant actinide metals is uranium. During actinide metal processing, impurities are common and can be costly for manufacturers.

A team of scientists at Pacific Northwest National Laboratory (PNNL) developed new computational models to predict the behavior of these impurities and reduce the expense and risk related to actinide metal production.

The team shared their research in a new article, titled “Computational studies of impurity migration during induction stirring of molten uranium.”

The PNNL authors are Rajesh Singh, Jordan Corbey, Nikhil Deshmukh, Amanda Howard, William Frazier, Shenyang Hu, and David Abrecht.

Strengthening nuclear security and energy goals

Carbon is the most common impurity in uranium metal production and appears as hard inclusions that can cause fractures and undesirable properties in uranium parts during manufacturing.

“Actinide metal parts are manufactured at large scales for the nation’s security and energy missions,” said Corbey, a chemist and principal investigator of the project. “These actinide products must meet specifications, and new production methods are stimulating new validation techniques. At industrial scales, it can be expensive and impractical to comprehensively characterize a multi-kilogram part, for example.”

The PNNL team’s research helps actinide metal producers better understand their processes and products. Ultimately, the PNNL team believes that creating more efficient processes to produce actinide metals will decrease costs, while improving worker safety and health.

“Fundamental computational models like ours are the first step toward visualizing the behavior of impurities in these strategic materials during their most reactive stages—when they are molten,” said Corbey. “They can give us a window into processing steps that may be experimentally unavailable and provide manufacturers with greater confidence in the quality of their products, along with more efficient throughput.”

New twist on existing research

For nearly a decade, PNNL scientists have been exploring carbon impurity migration in kilogram-scale uranium and uranium-alloy castings using a laboratory-scale induction furnace.

According to Corbey, the team’s specific research of computationally modeling the movement of particles in molten actinide metal influenced by an electromagnetic field is relatively new for PNNL. The authors began the research for this project in fiscal year 2020.

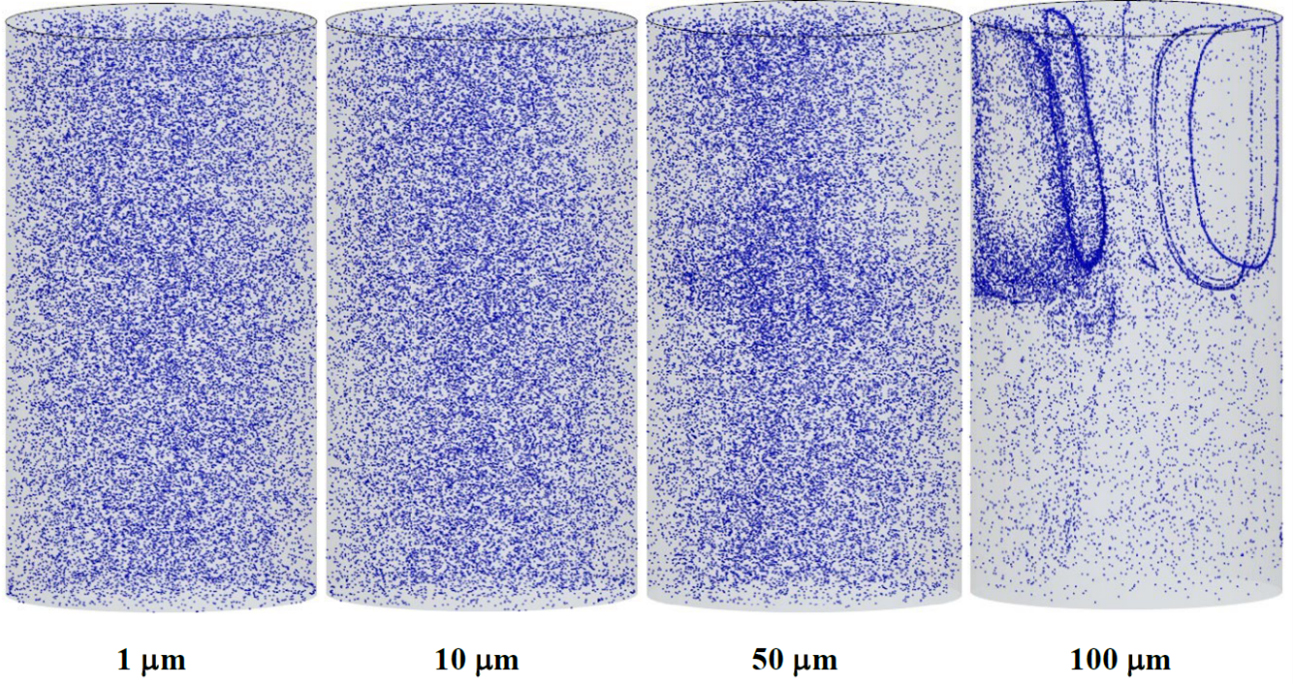

Through computational fluid dynamics models, the team found that the size of the impurities made a big difference.

“This study focused on carbon impurities in uranium melts,” said Corbey. “Once the carbon-containing particles become larger than about 50 micrometers in diameter, they are predicted to migrate toward the top of the melt pool, possibly making them easier to remove.”

Their industry collaborators, who manufacture uranium metal parts, have shown interest in the details of their simulations. Using their findings, the companies can tune their processing parameters to predict how certain impurity properties will behave.

“Providing the nation’s actinide metal manufacturers with reliable, efficient tools for assessing the quality of their products helps secure production pathways for these strategic materials,” said Corbey. “It will lead to greater confidence in the supply chains associated with robust national nuclear energy and security landscapes.”

Published: December 1, 2023

Rajesh K. Singh, Jordan F. Corbey, Nikhil S. Deshmukh, Amanda A. Howard, William E. Frazier, Shenyang Hu, David G. Abrecht. 2023. "Computational studies of impurity migration during induction stirring of molten uranium." Computational Materials Science, Volume 229, 2023, 112386, ISSN 0927-0256, https://doi.org/10.1016/j.commatsci.2023.112386.