Objectives

Objective 1: Accelerate modeling-based prediction of material microstructure

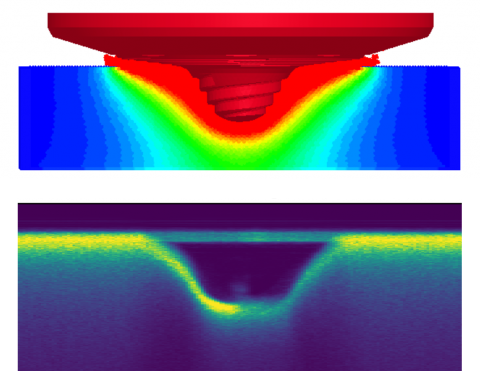

MCPC is pursuing targeted application of high-fidelity models for fundamental mechanisms, lower-resolution models to characterize trends across broad ranges of the process parameter space, and science-informed machine learning to accelerate the discovery and interpretation of relationships across length and time scales.

Existing high-fidelity multiscale modeling methods are computationally expensive, often requiring high-performance computing to achieve a useful level of accuracy, even for simplified materials systems. The result will be new modeling approaches that can dramatically accelerate the prediction of material microstructure for a given set of process conditions, thereby enabling the accurate mapping of the full multidimensional process parameter space using large numbers of experiments in silico.

Objective 2: Apply advanced diagnostics for real-time, inline validation of product characteristics

A major drawback of traditional development and qualification approaches is that sampling of the final product and subsequent destructive analysis in the laboratory is generally necessary to confirm that the product meets requirements.

MCPC will develop and apply advanced diagnostics, including process monitoring signals from the manufacturing process and inline nondestructive examination methods for the product material to achieve real-time validation of product characteristics, thereby reducing the need for costly and time-consuming off-line sampling and laboratory analysis.

Objective 3: Develop physics-informed data analytics tailored to materials processing

The increasing maturity of machine learning offers the potential for data-driven, and physics-informed, advances in surrogate modeling of microstructures, image analysis for microstructure characterization, interpretation of complex signals from nondestructive examination instruments, real-time process control, and uncertainty quantification in support of experiment design.

Objective 4: Demonstrate an integrated framework to support process qualification by our partners

Meeting the mission needs of our sponsors in national security and nuclear energy requires that we show how an integrated framework—consisting of accelerated modeling, advanced diagnostics, and modern materials analytics—can accelerate qualification of new materials systems in actual production environments. PNNL, as a science-focused organization, will collaborate with our production-focused partners to understand how our framework could be transferred into their production use cases—under their performance, operational, and regulatory environments.