Advanced Cement and Concrete Technologies

Next-generation, high-performance cement and concrete

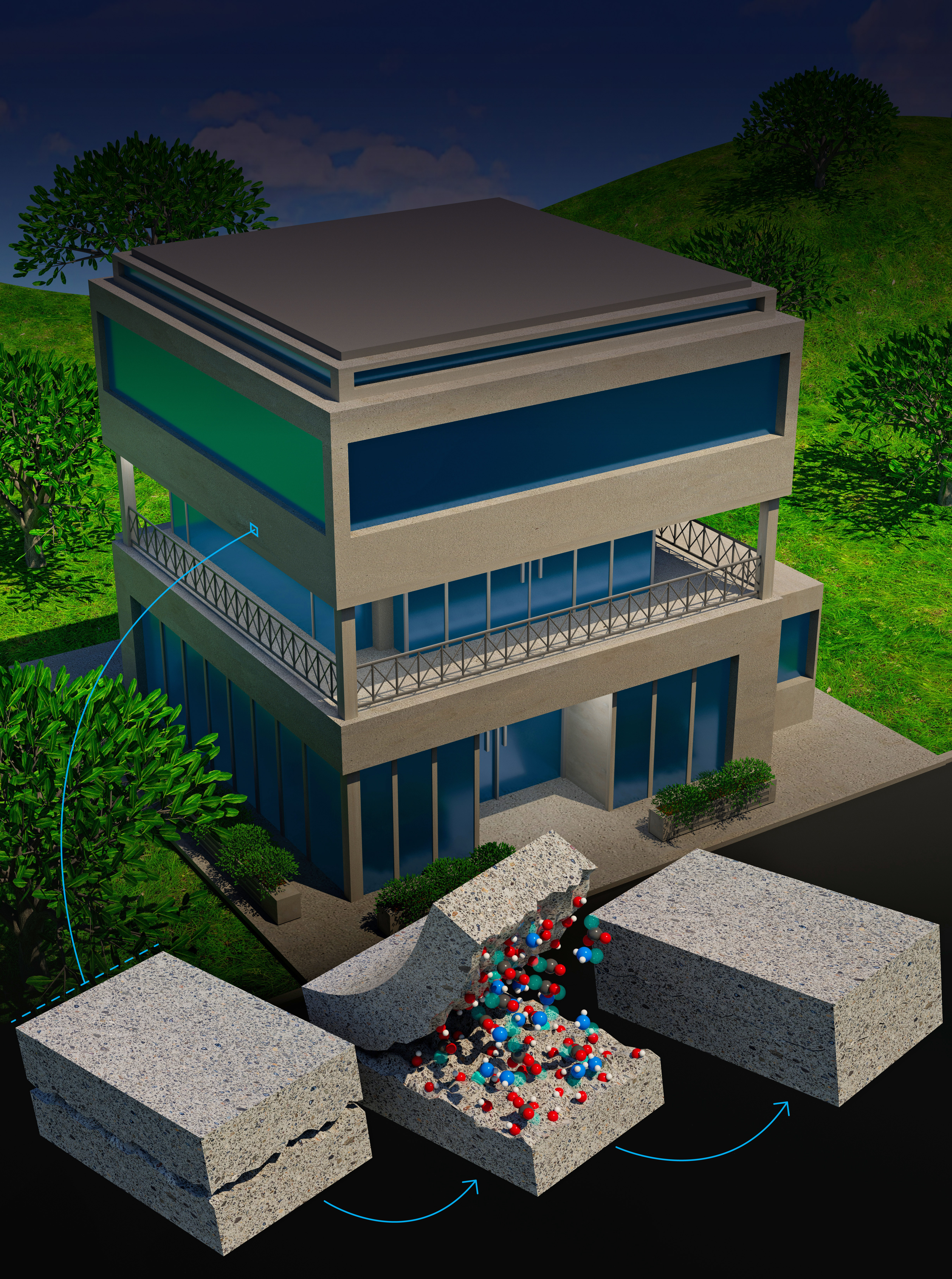

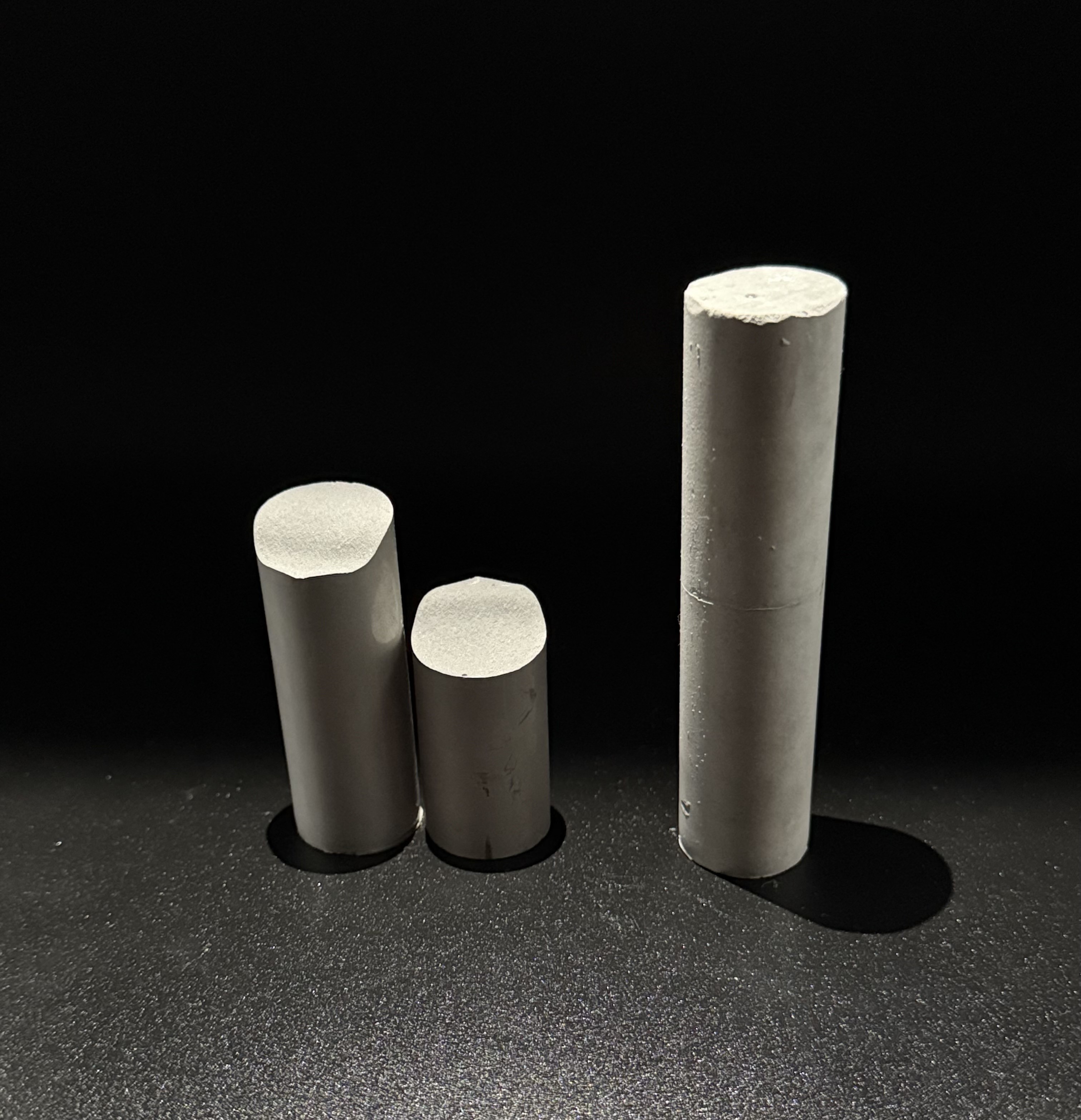

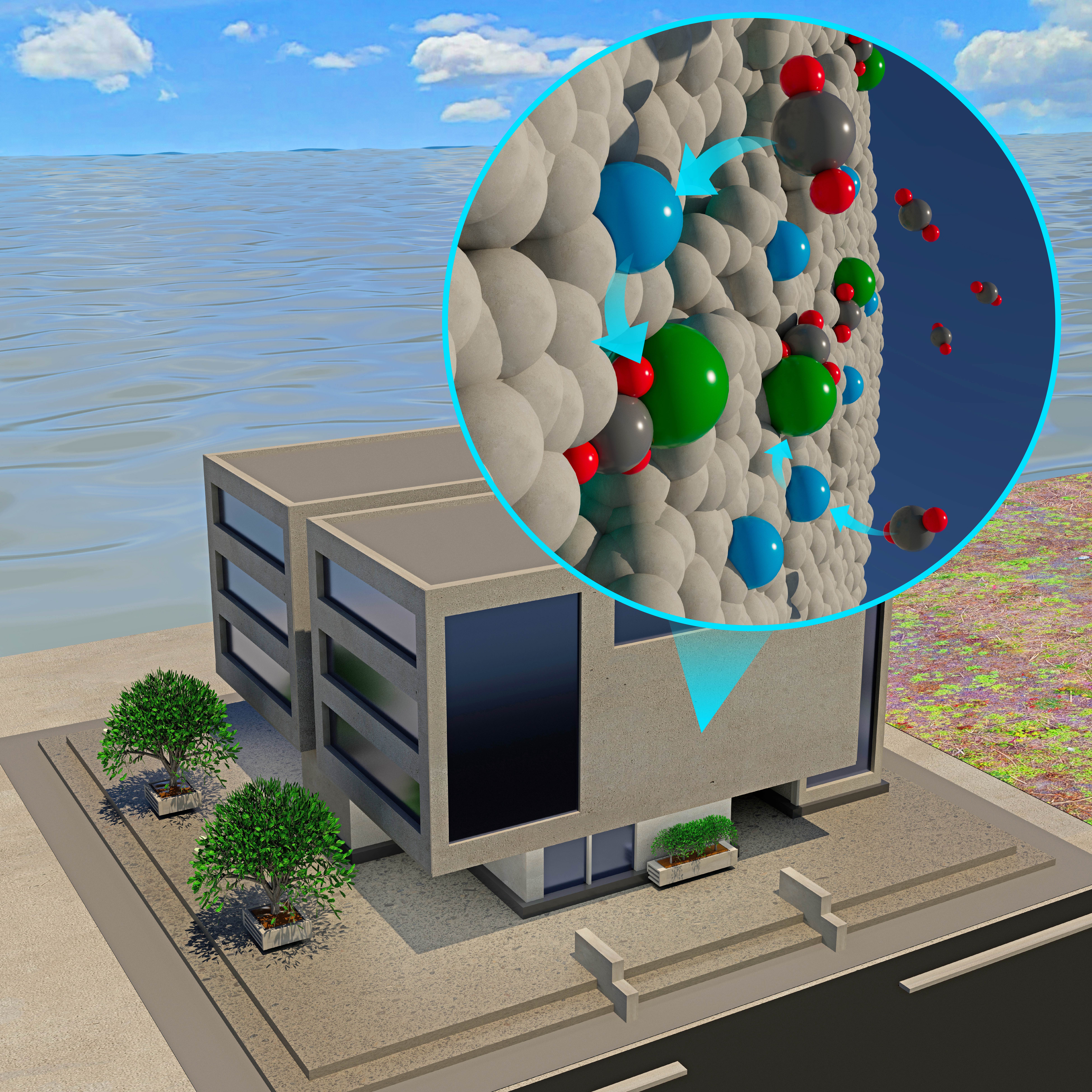

Hydrothermal liquefaction of algae blooms produces algal biochar, a cumbersome waste product. That biochar can be used as a supplemental cementitious material in the production of cement, allowing harmful algal blooms to become bio-crude and cement.

(Photo by Andrea Starr | Pacific Northwest National Laboratory)