PNNL Turns Algae into Fuel and Cement

Research shows waste from algae-to-fuel conversion can be used as a cement supplement

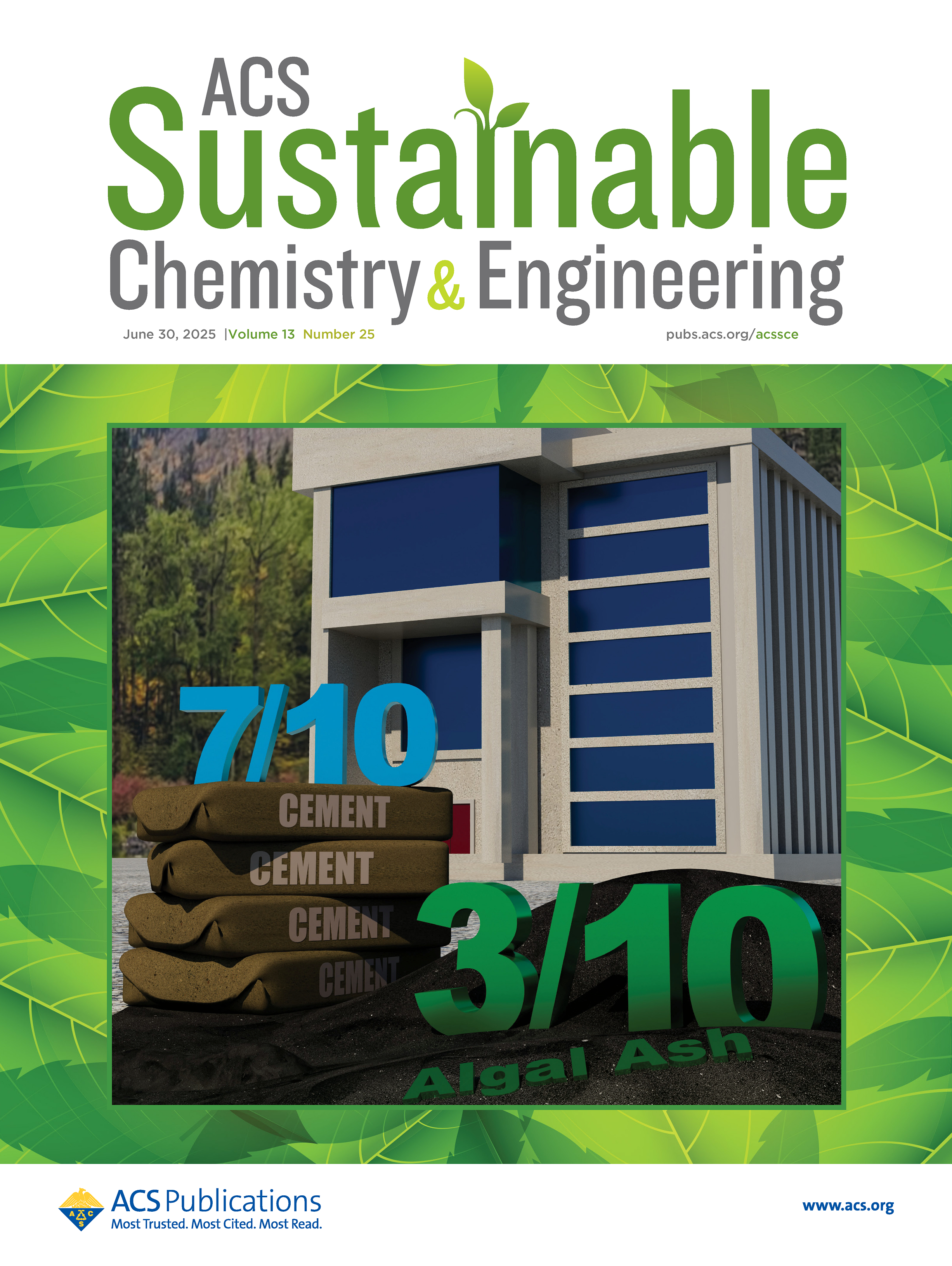

Researchers at PNNL are using a waste production from hydrothermal liquefaction—algal biochar—as a supplementary material for cement (right) that compares favorably to cement made with conventional, costlier supplementary materials (right).

(Photo by Andrea Starr | Pacific Northwest National Laboratory)

The hydrothermal liquefaction (HTL) process advanced by bioenergy researchers at Pacific Northwest National Laboratory (PNNL) can turn wastes and biomasses ranging from sewage sludge to fry crumbs into commercially viable biofuels and products.

Algal blooms, which form in nutrient-saturated water and can be toxic, are another feedstock of particular interest. When HTL is used on harvested algal blooms, the process makes two things: bio-crude (which can be upgraded into all sorts of biofuels) and a solid waste called algal biochar.

Currently, that algal biochar is waste: it heads to landfills, adding cost to the HTL process. But now, PNNL researchers have found yet another way to turn trash into treasure: using the algal biochar as a supplementary material for cement.

A second life for algal biochar

In the concrete industry, supplementary cementitious materials (SCMs) are used to replace 20 to 30 percent of cement. When cement cures, it produces a lot of undesired calcium hydroxide; the silicon and aluminum found in SCMs react with that calcium hydroxide to form more of the compounds that give cement its strength.

“When we looked at the composition of algal biochar—calcium, silicon, aluminum, iron—we realized: these are the components of cement,” said Carlos Fernandez, chief chemical engineer for materials at PNNL.

So, the PNNL team tested algal biochar as an SCM: they used it to replace 30 percent of a cement mixture, let it cure for a month, and assessed the material’s compressive strength (resistance to inward-pushing force) and tensile strength (resistance to outward-pulling force).

The results were very promising.

“We found that the cement’s compressive strength started off lower than commercial options but caught up within a few weeks,” explained Lan Li, a mechanical engineer at PNNL. “For tensile strength, it was the opposite—but we’ve been testing methods for activating the mixture to increase its tensile strength.”

Algae-to-fuel, waste-to-cement

While algal biochar isn’t yet a perfect replacement for commercial SCMs, it has two enormous advantages over the competition: cost and availability.

Popular commercial SCMs include industrial byproducts like fly ash, silica fume, and blast furnace slag—all of which are increasingly expensive or limited in the United States. Meanwhile, the multi-billion-dollar U.S. market for SCMs is rapidly growing, with demand expected to soon outstrip supply.

“The cost of algal biochar is competitive with commercial SCMs—and that’s not including the avoided landfill costs,” said Peter Valdez, senior chemical engineer for biofuels at PNNL. “And there are no supply issues: the United States could use its emerging algae resources to produce 30 million tons of algal biochar per year via HTL—which could supply around a third of annual U.S. SCM demand.”

“Biochar had been overlooked for some time,” Valdez added. “This research demonstrates that biochar has a viable industrial application—meaning that HTL can turn one low-cost domestic material—algae—into two high-value commercial products.”

This research was supported by the Department of Energy, Office of Energy Efficiency and Renewable Energy’s Bioenergy Technologies Office. The research was published in the June 2025 issue of ACS Sustainable Chemistry & Engineering, which also dedicated its cover art to the breakthrough.

Published: September 5, 2025