Materials Science and Technology Building

Identifying and predicting degradation of materials before failure

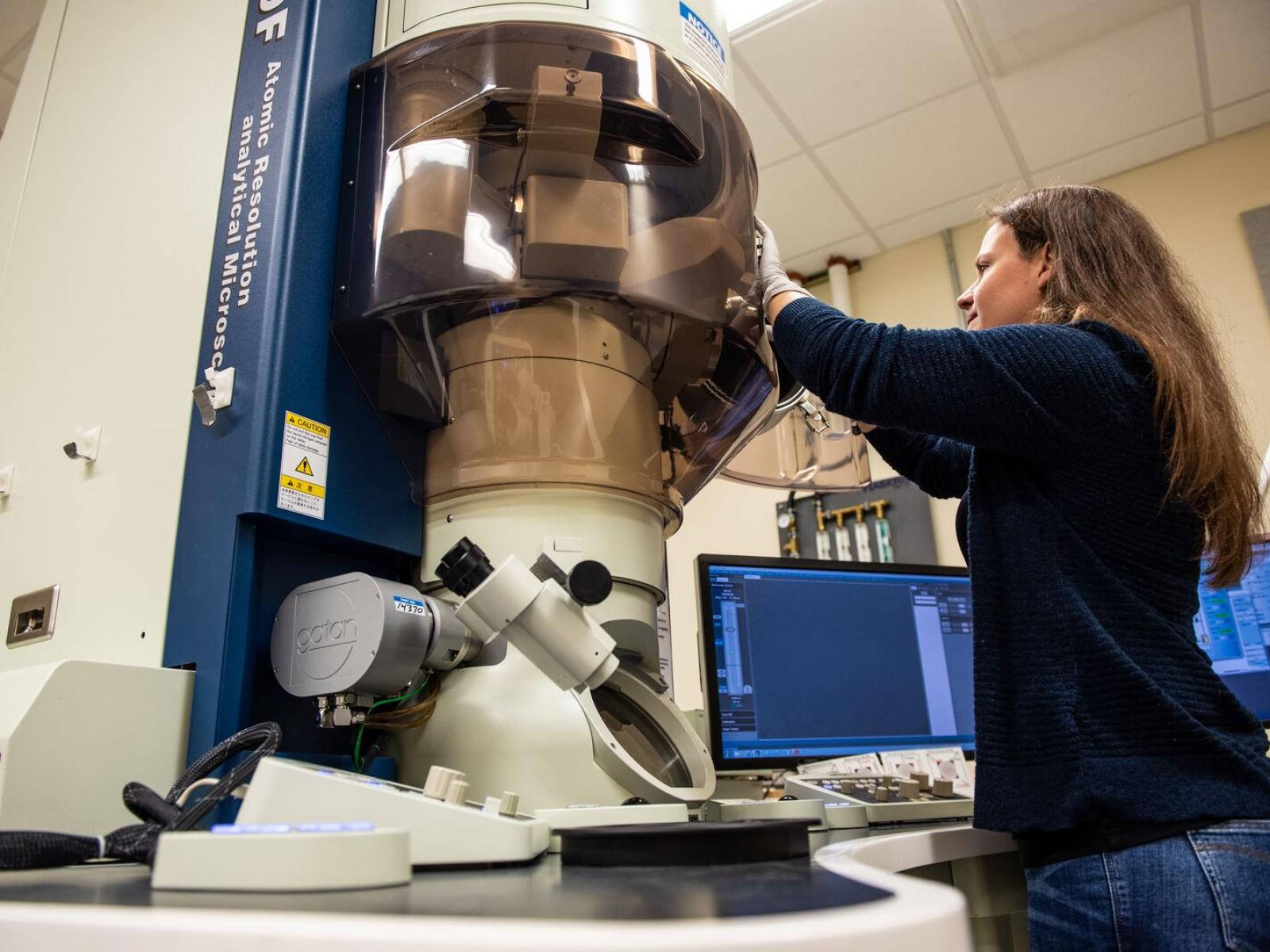

Among the technology capabilities based in the Materials Science and Technology Building is the JEOL ARM 200CF STEM, which enables unmatched spatial resolution for atom-to-atom chemical mapping of materials, including energy-dispersive X-ray spectroscopy and electron energy-loss spectroscopy. (Pictured in photo: Karen Kruska, materials scientist, Nuclear Sciences Division)

Expertise and equipment in the Materials Science and Technology Building is focused on identifying and predicting how materials degrade in extreme environments, particularly before macroscopic damage propagates and leads to the failure of systems, structures, and components important to safety.

Focused on advancing understanding of how materials age and degrade, this facility features a host of capabilities including atomic-resolution electron microscopy, materials testing in realistic environments, mechanical design, and multiscale modeling.

An interdisciplinary team of materials scientists and nuclear engineers conduct fundamental scientific research and solve real-world problems.

Located at 3410 Horn Rapids Road, the Materials Science and Technology Building features capabilities for researchers to:

- Characterize stress corrosion cracking to provide insight into failure mechanisms and enable safe and reliable nuclear power

- Develop robust materials that can withstand the extremes of radiation, high temperature, stress, and corrosion

- Use multiscale modeling, simulation, and physics-informed machine learning to augment experiments providing the technical basis for nuclear fuels, advanced structural materials, and fusion plasma-facing materials

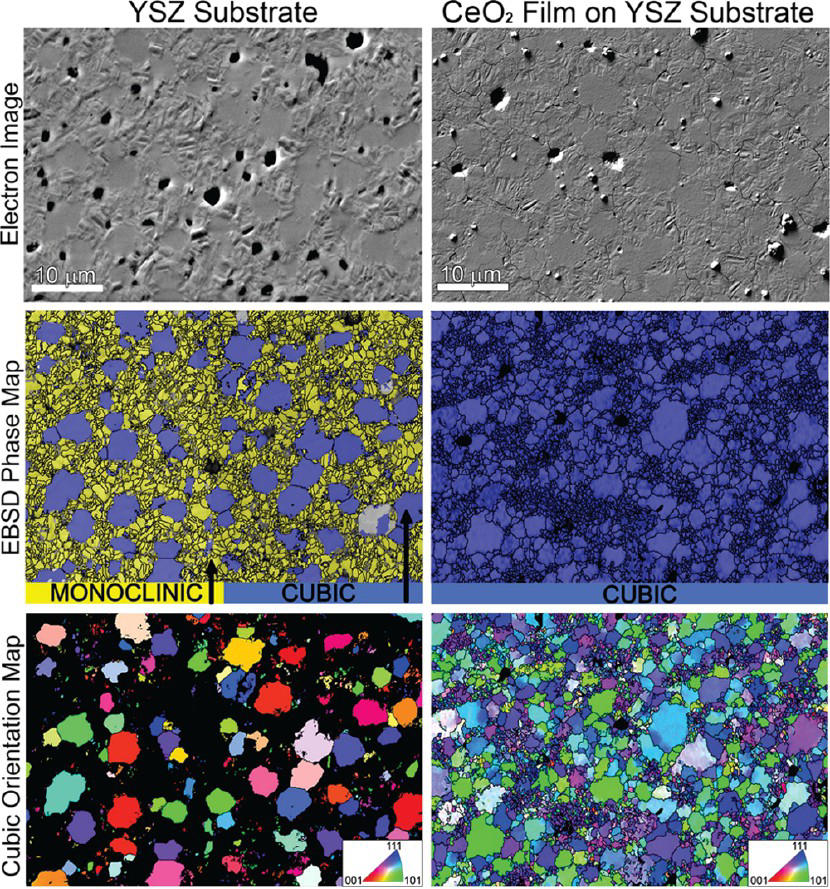

- Employ electron microscopy and microanalysis including optical metallography, electron backscatter diffraction, atom probe tomography, and chemical imaging at the atomic level

- Detect and analyze damage from neutrons, high temperatures, corrosion, transmutation, and high concentrations of gases such as helium and hydrogen

- Apply post-irradiation examination for materials using novel sample preparation techniques, which can produce small analytical samples with little to no detectable levels of radioactivity. This is done by leveraging the capabilities in PNNL’s Hazard Category II nuclear facility, the Radiochemical Processing Laboratory (RPL)

- Develop new metal fuel fabrication techniques, such as rolling and extrusion of fuel, mechanical testing at elevated temperatures, and high-resolution characterization, to support the development of new fuel materials and geometries and serve the next generation of nuclear reactors.