Preparation and Communication Essential for Nuclear Safeguards Projects

Remote work hones students’ engineering and communication skills and enables successful delivery of Nuclear Safeguards projects

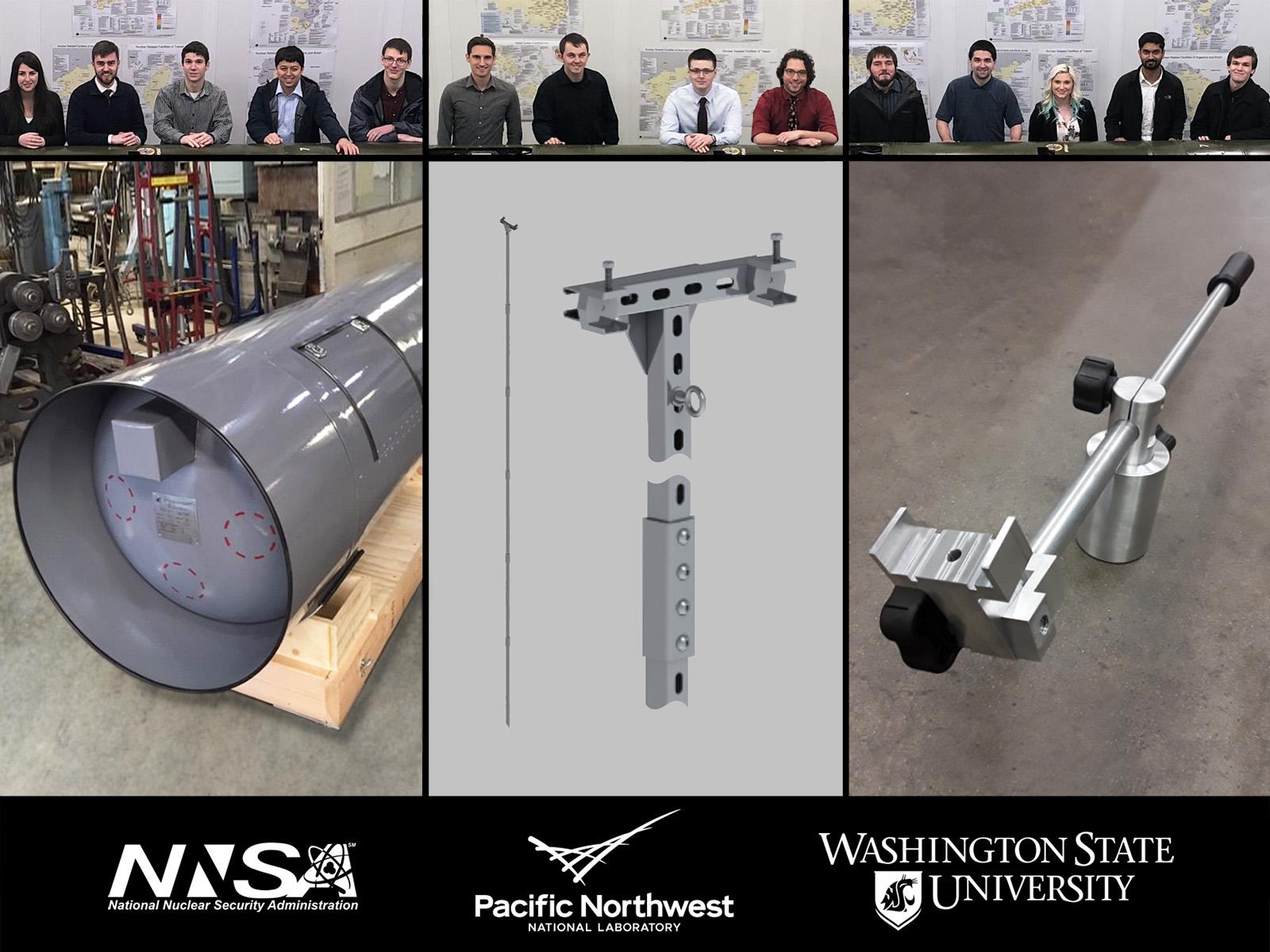

WSU engineering student teams (photos taken before COVID-19 social distancing orders took effect) and their prototype equipment designed and fabricated to address challenges to nuclear safeguards research at PNNL; (left to right) are the UF6 Cylinder Test Form, System for Positioning Sensors, and Rail Mounting Fixture.

In southeastern Washington State, remote work is not uncommon for scientists and engineers at research organizations like Pacific Northwest National Laboratory (PNNL). Leveraging that experience during the state’s response to COVID-19, students and faculty at Washington State University (WSU) and PNNL mentors enabled the success of a program that trains the next-generation workforce and provides solutions to nuclear safeguards challenges.

For more than 10 years, the National Nuclear Security Administration Office of International Nuclear Safeguards has sponsored a program where WSU engineering students enrolled in the Industrial Design Clinic design, fabricate, and deliver prototype equipment that addresses the challenges PNNL research staff encounter in nuclear safeguards research. This semester, three teams of students faced an additional challenge—project execution in a remote working environment.

Preparation and communication essential for remote work

“I envisioned the worst case—the students working on their projects remotely—then the PNNL team and I made more effective use of the remote strategy we already had in place. At WSU, I worked with students to understand the working conditions and helped the fabrication shops prepare to work in this environment,” said Dr. Chuck Pezeshki, instructor of the Industrial Design Clinic.

For many students in this program, this is their first exposure to nuclear safeguards and their first experience in delivering a physical engineered solution to a real-world need. With the added restrictions of virtual work in all facets of the project, successful fabrication and delivery relied upon communication of detailed and accurate designs and plans.

“It makes a difference when one can physically handle the equipment. With the remote work, final designs evolved later in the project,” said PNNL engineer and mentor Patrick Valdez, a WSU alumnus himself. His weekly conference calls with the students reinforced the need for frequent communication with fabricators and researchers to help the teams succeed.

The WSU student teams undertook the following projects and presented their prototype equipment in a virtual delivery to PNNL researchers and mentors in May:

- UF6 Cylinder Test Form to represent actual safeguards verification activities in training situations

- System for positioning sensors to collect reactor pool temperatures

- Rail Mounting Fixture for custom instruments to verify spent nuclear fuel under water in storage pools.

The WSU teams included Carter Barnett, Chelsea Crabb, Levi Davis, Tyler Hill, Aaron Hulburt, Bryson Jaipean, Anthony Kovic, Alex Lambert, Taylor McGriff, Seth McPherson, Ryan Sadler, Trevor Skinner, Noah Thompson, and Cyril Varghese.

Published: June 26, 2020