Technology Overview

From clogged pipelines to fouled medical devices and biofilm-covered sensors, surface contamination costs industries billions each year. This biofouling is a problem that affects ecological and human health, energy infrastructure, and machine performance. In marine settings, biofouling is the leading cause of aquatic invasive species transport, and biofilms thinner than the width of a human hair can increase drag on a ship by 22 percent.

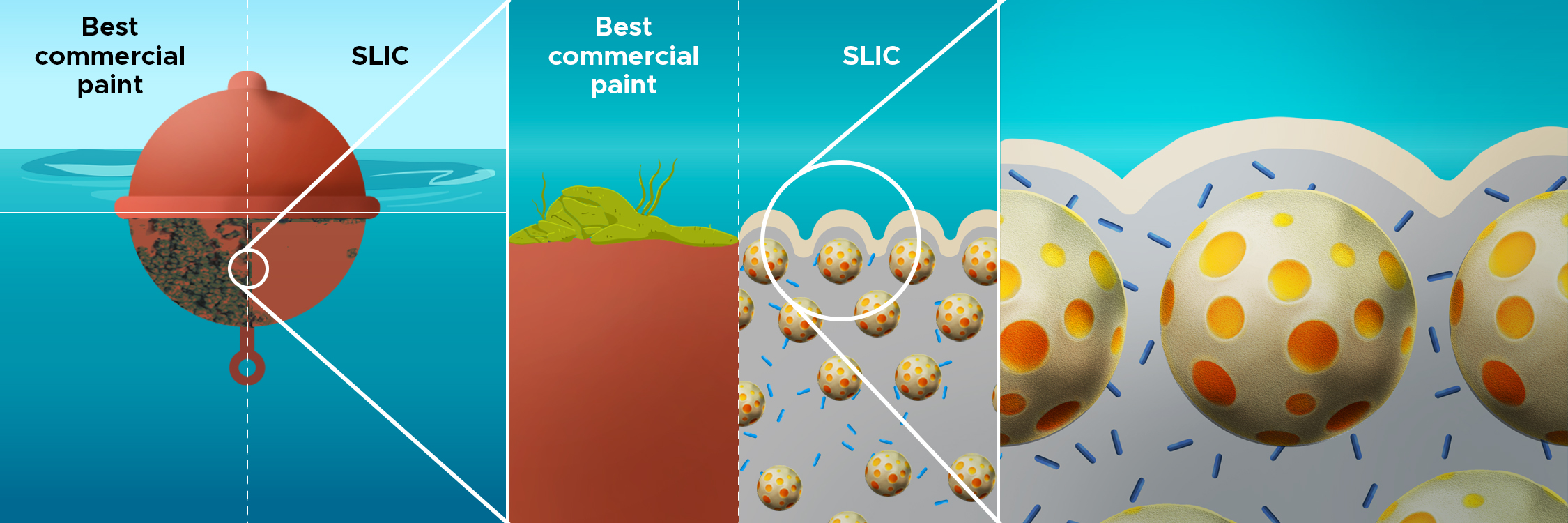

The current approach to preventing biofouling is to coat surfaces with chemicals that are toxic to living organisms—and often to the surrounding environment—to dissuade this unwanted growth of microorganisms. These coatings may also have limited durability and require complex, expensive processes to produce and apply.

Researchers at Pacific Northwest National Laboratory developed a Superhydrophobic Lubricant Infused Composite (SLIC) coating that is nontoxic, durable, hydrophobic, and 10 times more liquid-repellant than Teflon. SLIC technology introduces a smarter way to keep surfaces cleaner for longer by altering how they behave at a microscopic level while dramatically reducing maintenance, downtime, and chemical usage.

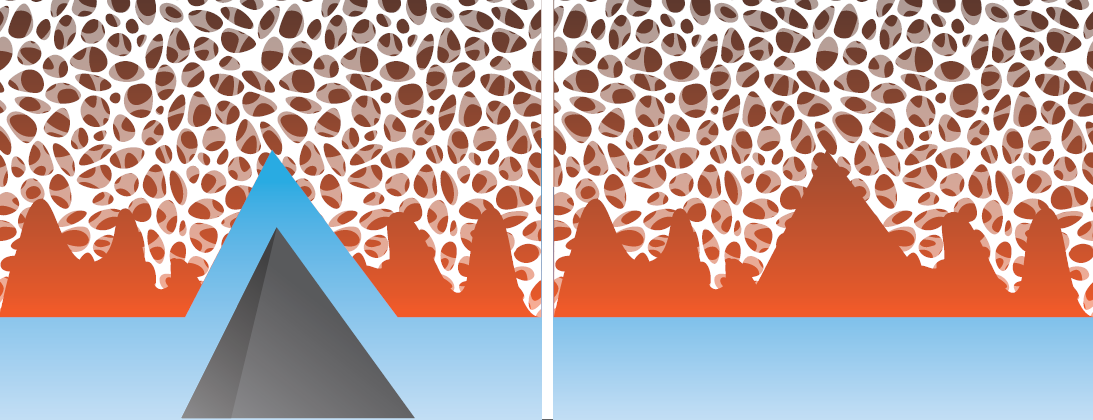

Its unique surface nanostructure holds in place a lubricant oil that repels biofouling. Its paintable nanostructure comprises two types of silica particle materials that are inexpensive and readily available. The composite is also self-healing, increasing the durability and lifetime value of the coating application.

SLIC may be applied to large and irregular surfaces by conventional means, such as paint brushes, spray coating, and dip coating, and it can be manufactured using common industrial processes.

HOW IT WORKS

The SLIC coating is composed of a common nontoxic polymer, nanoporous silica particles that act as lubricant reservoirs, fine silica particles that increase the durability of the coating, and a canola-based lubricant. This microscopically engineered surface prevents fouling organisms and substances like dirt, bacteria, algae, and ice from sticking to the polymer surface.

When compared to a leading commercial foul release coating, SLIC has a lower surface energy and roll-off angle, has similar abrasion resistance, adheres better to commercial primers, has greater tear resistance, and is nontoxic. SLIC exhibits superior antifouling capabilities in laboratory testing and in field testing with over 1 year of exposure to a marine environment. The benefits of SLIC as an antifouling coating could enable the effective prevention of biofouling without endangering surrounding ecosystems.

APPLICABILITY

SLIC enables long-term resistance to icing, fogging, scaling, and corrosion while maintaining durability under harsh conditions. Compared to conventional hydrophobic coatings or chemical antifouling treatments, SLIC offers longevity and reduced friction without leaching toxic agents or requiring frequent reapplication.

SLIC is poised to be commercially applied across sectors requiring sustained surface performance, including marine, energy, medical, water treatment, and advanced manufacturing. Examples include aerospace, automotive, optics, health care, and consumer products. SLIC can be applied to both rigid and flexible surfaces, including fabrics, netting, and fiber-reinforced polymer membranes.

Other application areas:

- Hydroelectric power plants

- Marine and offshore systems

- Harbor facilities and structural members

- Food and agricultural processing plants

- Medical and health-care devices

- Water and wastewater treatment

- Aerospace and aviation

- Industrial manufacturing and tooling

- Oil and gas systems.

Advantages

- Self-healing for enhanced durability and lifetime

- Can be manufactured from inexpensive, readily available materials using common industrial processes

- Can be applied to large and irregular surfaces

- Persistent low-adhesion surface behavior

- Improved operational reliability and lifetime performance

- Compatibility with multiple substrate materials

- Scalable manufacturing potential

- Reduced maintenance burden.

For more information, please contact: commercialization@pnnl.gov

State of Development

Available for licensing in all fields