Technology Overview

Bio-based ethanol could be used to fully replace fossil-derived materials, if the material and process to create it could be improved to overcome some limitations. These limitations include lower selectivity and carbon efficiency of the product, long processing times, and high cost of conversion. Researchers at Pacific Northwest National Laboratory have developed a method to quickly and cost-effectively convert, in a single catalyst bed, an alcohol-containing feedstock to high-value upgraded materials.

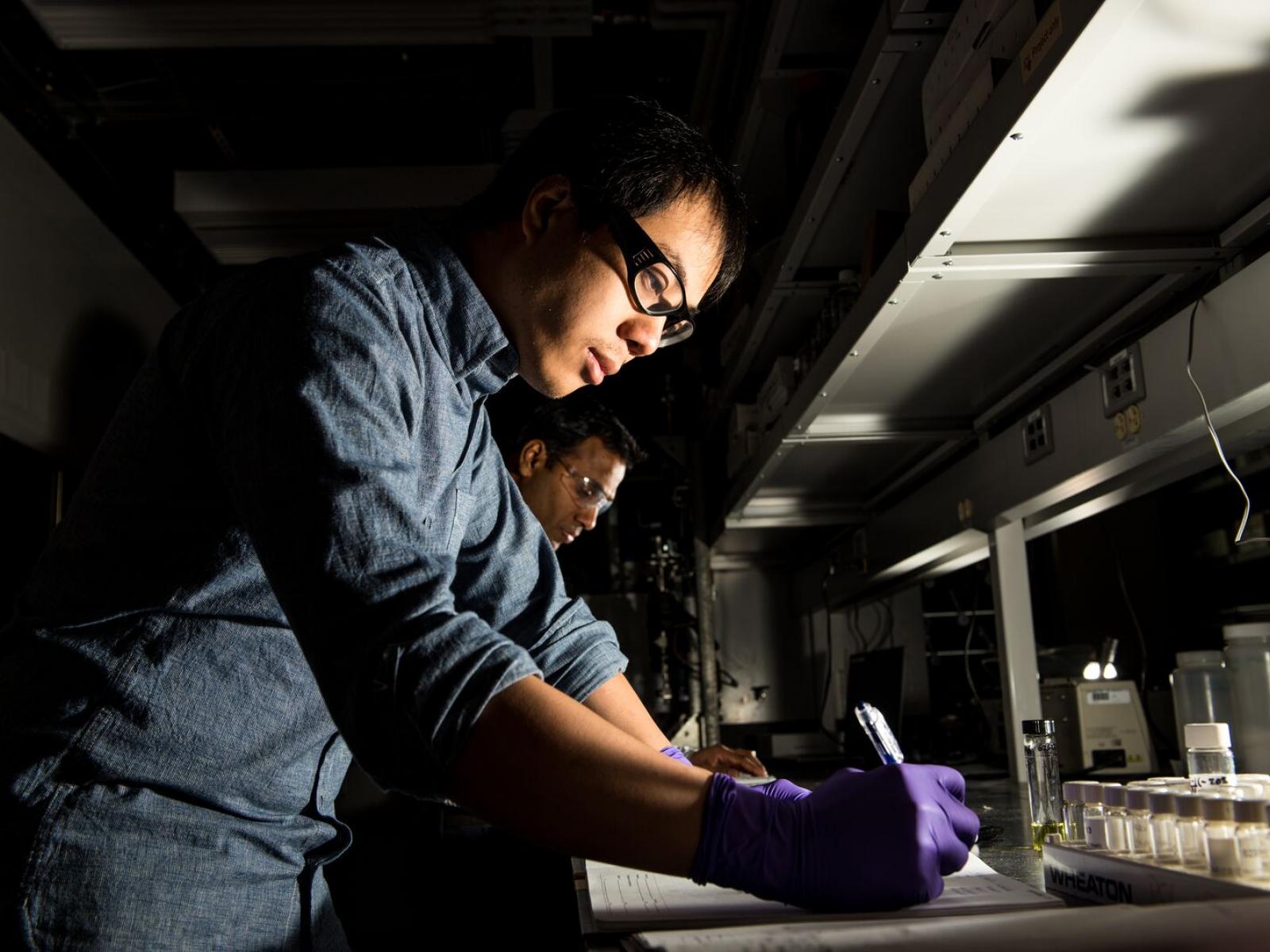

Single-Bed Catalyst

Using the method, alcohol, such as ethanol, is fed to a low-cost, mixed-metal, oxide catalyst under preselected conditions to yield an upgraded product. In many cases, this product is a C5+ ketone or alcohol, such as the highly useful 2-pentanone, 2-heptanone, 4-heptanone, and 2-nonanone. These ketones can be used as solvents in electronics manufacturing, intermediate to generate lubricant alcohols, fuel blends (e.g., octane and cetane booster), and infrastructure-compatible fuels (e.g., jet fuel).

Conditions for processing can include a temperature between 300 to 400 degrees centigrade and a pressure of 300 pounds per square-inch gauge. The method reduces the number of reaction steps and allows the materials to be developed in a simple and economically viable manner. The novel approach selectively converts ethanol to higher-value C5+ ketones with a greater than 70 percent yield. These materials can then be distilled and sold as value-added chemicals. For example, some 2-ketones sell for as much as $20 per kilogram, while ethanol averages $5 per kilogram.

Produce fuels and commodity chemicals in tandem.

APPLICABILITY

This method and catalyst, which provide a simple processing route to high-value chemicals, make possible a variety of new applications. The approach could be integrated into existing ethanol plants as an add-on process to produce fuels and commodity chemicals in tandem. Ketones produced under this method could also be used as food additives, fragrant agents, and solvents.

Advantages

- Uses a single-bed catalyst, which results in fewer conversion steps, reducing time and cost of production

- Can be integrated into existing ethanol plants to produce higher-value products

- Yields products at greater than 70 percent over a stable catalyst that was demonstrated more than 2,500 hours