Studying Lithium Silicates to Fuel Fusion Reactions

Researchers studied the microstructure of lithium silicates under emulated fusion conditions

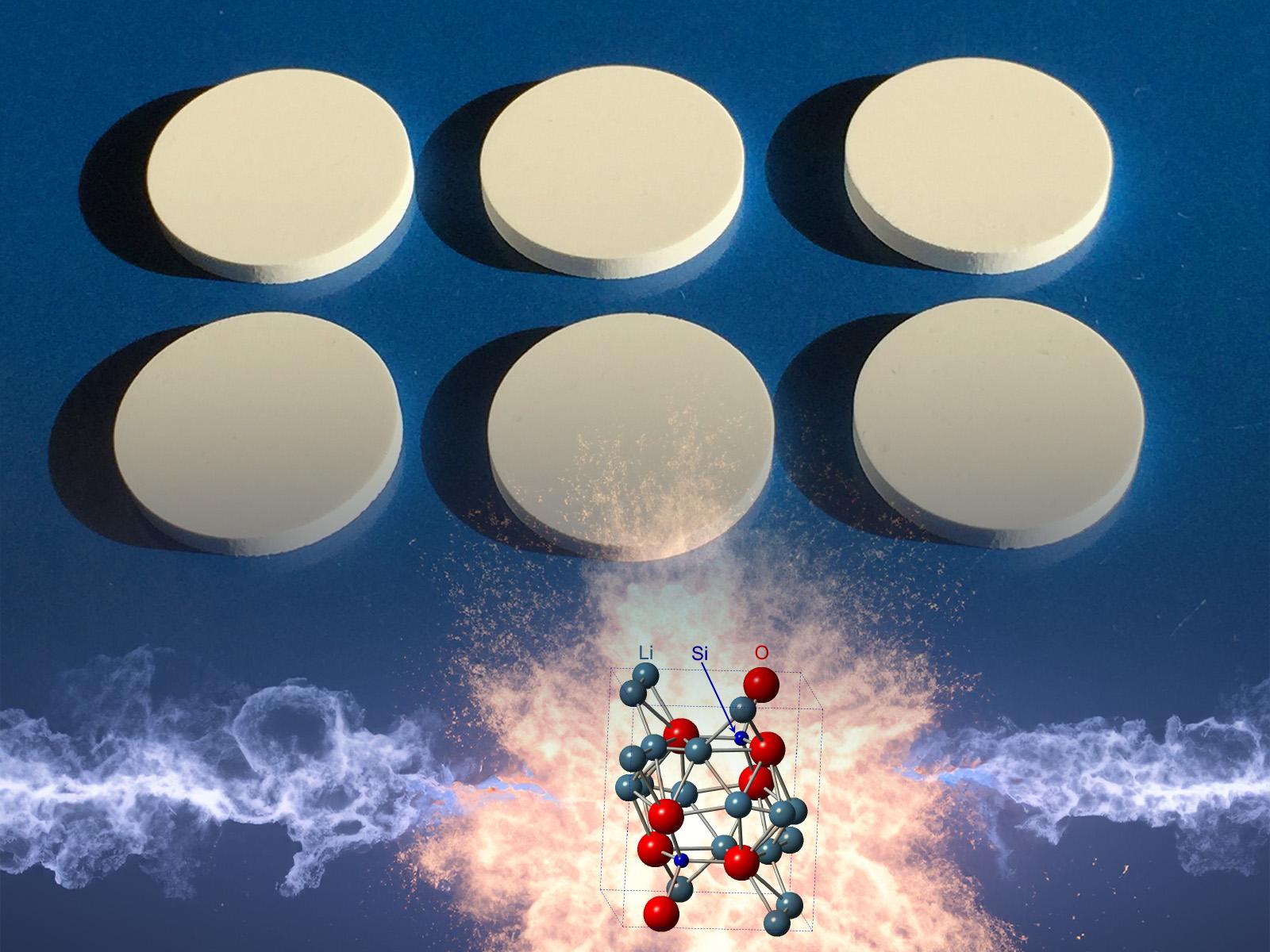

Hot-pressed lithium orthosilicate pellets can be used as a breeder material for nuclear fusion applications.

(Composite image by Shannon Colson | Pacific Northwest National Laboratory)

The Science

Researchers studied the behavior of lithium silicates under ion irradiation at high temperatures to emulate the conditions after one year inside the SlimCS DEMO fusion reactor. They first fabricated pellets of lithium orthosilicate (Li4SiO4) with lithium metasilicate (Li2SiO3), then irradiated the pellets with Si+, He+, and D+ ions at temperatures up to 500°C. Analysis of the irradiated materials shows that deuterium (and inferred tritium) release from the pellet is very efficient during ion irradiation at 500°C. This property is well suited for fusion blanket applications. The study also discovered that Li2SiO3 may be more irradiation resistant than Li4SiO4. In addition, their research suggests that coating lithium ceramics with pure nickel can minimize lithium loss under irradiation conditions.

The Impact

Tritium is a fuel for fusion reactors but must be produced on-site. This heavy isotope of hydrogen can be sourced from lithium—a naturally abundant element. However, finding a source material that displays good structural stability, rapid tritium release, and low lithium volatility under the extreme conditions of a fusion reactor remains a challenge. This research provides evidence of microstructural and compositional evolutions of lithium silicates under irradiation conditions. Furthermore, it shows that coating the ceramic with pure nickel may minimize lithium loss—indicating the combination of materials may be a suitable candidate for fusion applications.

Summary

This study demonstrates the microstructural and compositional evolutions, behavior of deuterium release, and lithium loss from lithium silicates under emulated fusion conditions. Researchers fabricated pellets of biphasic Li4SiO4 and Li2SiO3 using hot pressing of milled powders. They then sequentially irradiated the samples with Si+, He+, and D+ ions at temperatures up to 500°C to emulate the burnup of 6Li after one year inside the conceptual SlimCS DEMO fusion reactor.

Structural analysis results reveal that the crystalline Li4SiO4 phase was not observed in the irradiated depth region in this study. However, under the same conditions, Li2SiO3 remained crystalline in the damage peak region, suggesting that Li2SiO3 is more irradiation resistant than Li4SiO4. Data from this study also show that deuterium (and inferred tritium) release from the pellet is very efficient during ion irradiation at 500°C, accompanied by significant lithium loss. By thermal annealing the room-temperature irradiated pellets for 10 min at 500°C, the researchers achieved nearly complete deuterium release without an observable lithium loss. Additionally, they studied using nickel as a coating to minimize lithium loss without a significant impact on tritium diffusion and release. Their results indicate that nickel facilitates fast deuterium (and thus tritium) diffusion while providing a high energy barrier for lithium diffusion.

A portion of this work used the facilities of the Environmental Molecular Sciences Laboratory, a Department of Energy, Office of Science user facility located at Pacific Northwest National Laboratory.

Contact

Weilin Jiang

Pacific Northwest National Laboratory

weilin.jiang@pnnl.gov

Funding

The lithium silicate study was supported by the Department of Energy, Office of Science, Fusion Energy Sciences program (FWP 13784) and study on the effect of Ni coating was supported by the National Nuclear Security Administration.

Published: September 10, 2024

W. Jiang,et al. “ Ion irradiation study of lithium silicates for fusion blanket applications.” Journal of Nuclear Materials; 576, 154281 (2023). [DOI: 10.1016/j.jnucmat.2023.154281]