A Streamlined Process to Extract Magnesium from Seawater

Precipitation with sodium hydroxide in a flow-gel device enables the rapid extraction of magnesium from seawater in a new scalable process

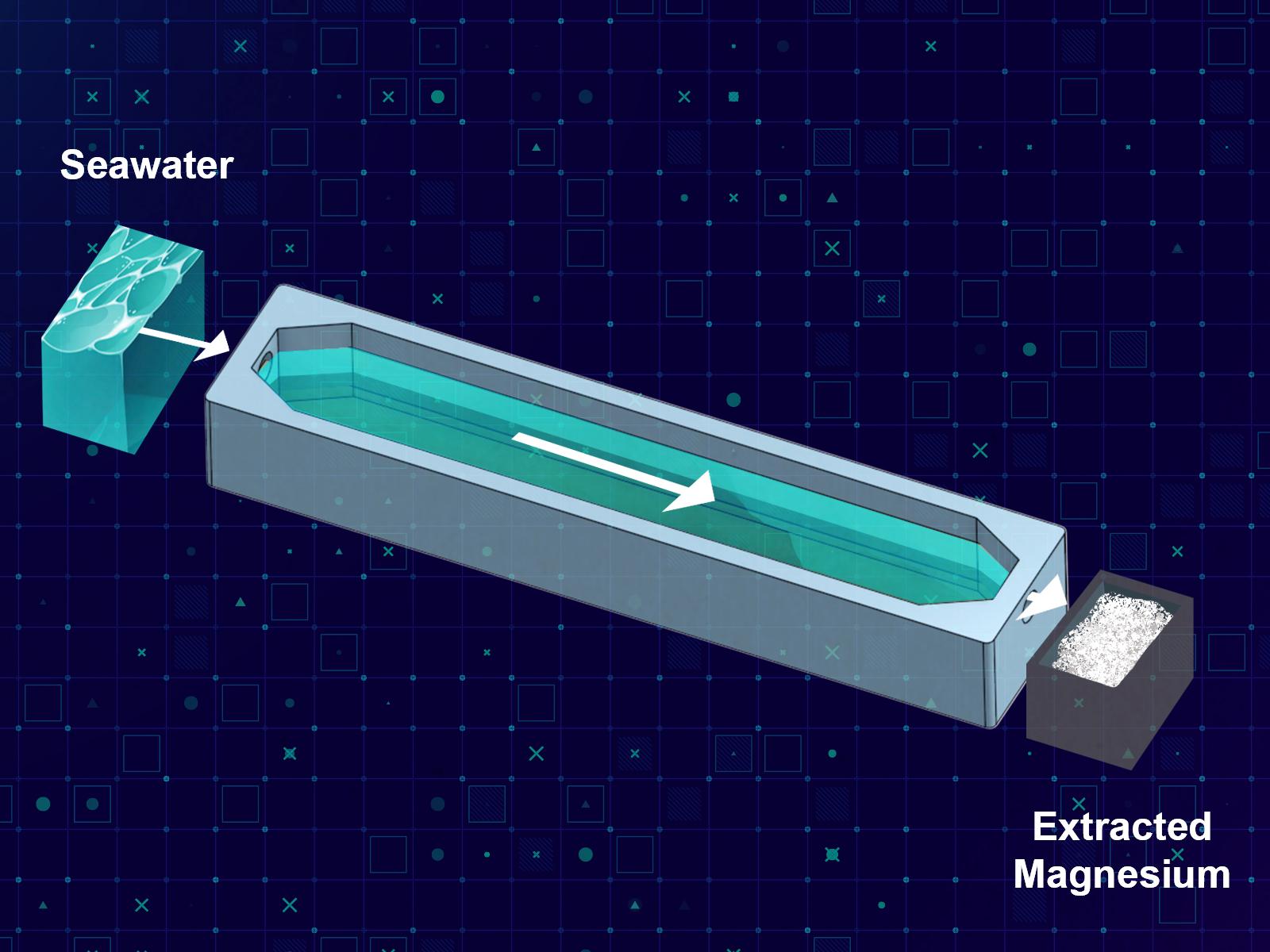

A streamlined flow-gel method allows researchers to separate the critical element magnesium from a solution of simulated seawater.

(Image by Stephanie King | Pacific Northwest National Laboratory)

The Science

Developing approaches to separating critical materials that require few specialty chemicals and are energy efficient is essential to meeting the growing needs for these elements. Researchers in the Non-Equilibrium Transport Driven Separations (NETS) initiative used a flow-gel method to separate a pure magnesium salt from a simulated seawater solution without using specialty chemicals or additional energy inputs. The gel was loaded with sodium hydroxide, and then the seawater solution was placed or flowed on top of the gel. In both scenarios, a solid, magnesium-based precipitate formed. The overall method showed higher separation efficiency than bulk mixing, with advantages for product recovery and capacity over other gel-based techniques.

The Impact

Magnesium is a critical element, essential for alloys and advanced energy storage and defense technologies. However, current domestic production processes for magnesium are energy and resource intensive. Developing a straightforward and scalable path to isolating magnesium from seawater, which is both highly abundant and accessible, will allow the US to maintain a consistent supply of magnesium to meet growing industrial needs. Additionally, the flow-gel process opens the door to a wider range of magnesium sources, including various industrial waste streams, and can reduce environmental burdens.

Summary

Current methods for critical materials separations are both chemistry and energy intensive, particularly those targeting feedstock solutions rather than traditional mined ores. Meeting the increasing need for these materials requires developing new separation approaches. Researchers developed a new flow-gel based method that uses affordable, available chemicals and minimal additional energy inputs. This method combines advantages from the laminar co-flow and gel-based chromatography approaches, with improved separation efficiency, capacity, throughput, and product recovery compared to conventional approaches. The team found that placing or flowing a model seawater solution over a sodium hydroxide-inoculated gel enabled the separation of magnesium. These initial benchmarking experiments highlight the promise of this approach, with future optimization likely to improve overall yield and efficiency. The NETS team is currently exploring the commercialization of this approach with industrial collaborators.

Contact

Elias Nakouzi, Pacific Northwest National Laboratory, elias.nakouzi@pnnl.gov

Funding

The initial experiments were supported by the Open Call Initiative, under the Laboratory Directed Research and Development (LDRD) program at Pacific Northwest National Laboratory (PNNL). The systematic experimental study, flow-gel device development, and model/scaling analysis were supported by the LDRD program at PNNL, under the NETS Initiative. This work is the subject of a provisional patent.

Related Links

Recovery of neodymium and dysprosium from magnet feedstock solutions via reaction-diffusion coupling

Published: December 5, 2024

Butreddy P., A.J. Ritchhart, Q. Wang, H.M. Job, M. L. Sushko, J. Chun, and E. Nakouzi. 2024. "Flow-gel approach enables rapid extraction of pure magnesium phase from seawater." Chemical Communications, 60, 13718-13721. [DOI: 10.1039/D4CC04711G]