Revealing the Distribution of Helium Cavities in a Toughened Tungsten Composite

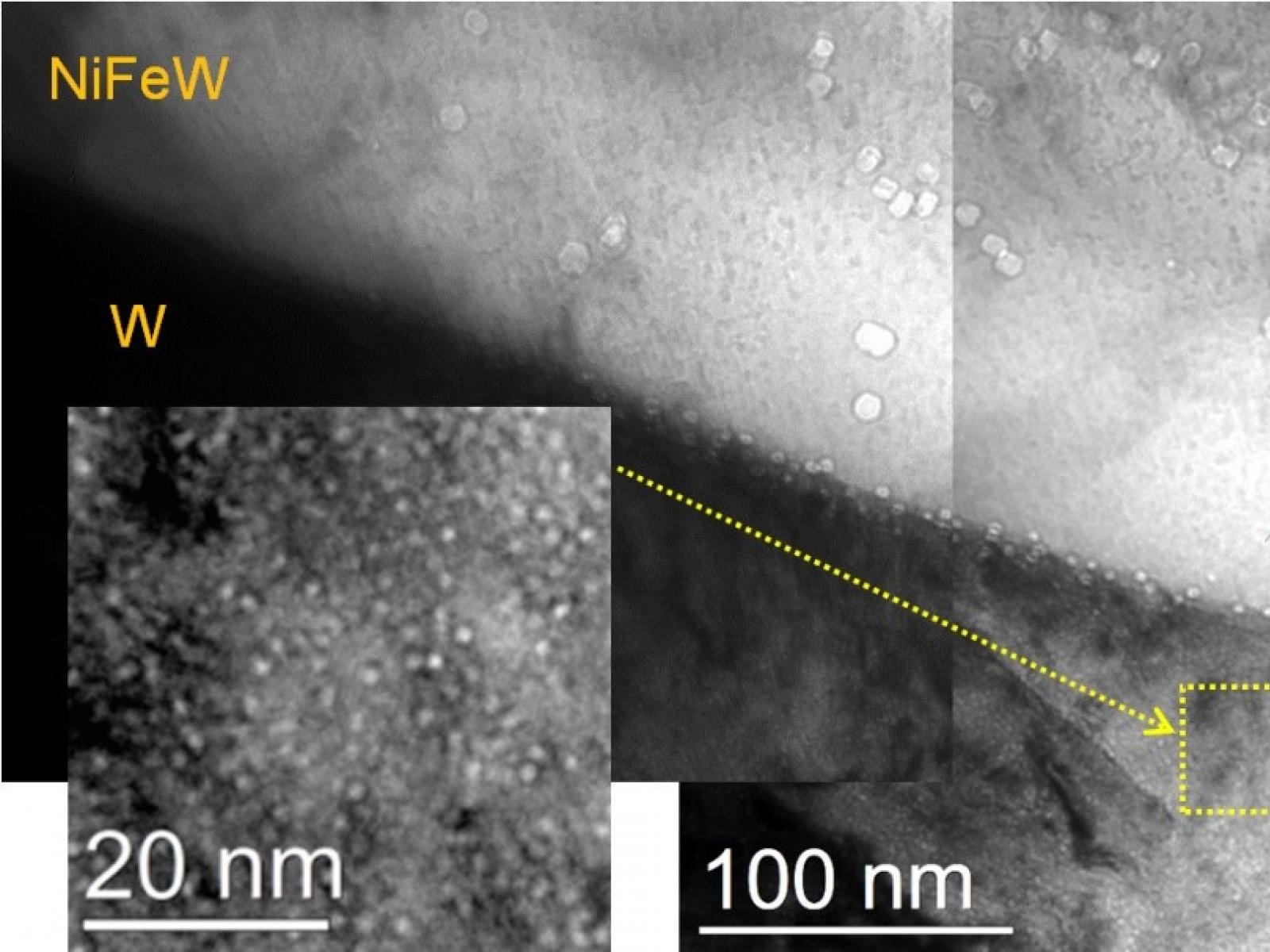

Different sized helium cavities formed after ion irradiation are unevenly distributed in a ductile-phase toughened tungsten composite

The presence of helium cavities at the interphase boundary in a toughened tungsten composite material increased its overall brittleness.

(Image by Weilin Jiang | Pacific Northwest National Laboratory)

The Science

Composite materials of brittle tungsten (W) and a ductile phase containing W, nickel (Ni), and iron (Fe) are promising candidates for plasma-facing components in fusion reactors for future clean energy systems. However, these reactors produce extreme conditions that require highly stable materials. Researchers emulated fusion neutron irradiation conditions by irradiating the W-Ni-Fe composite with Ni+ and He+ ions at an elevated temperature. They observed that helium (He)-filled cavities formed throughout the material after irradiation. These cavities varied in size in the different phases and preferentially aggregated at interphase boundaries.

The Impact

How the mechanical properties of W-Ni-Fe degrade depends on the size, distribution, and number density of He cavities. The He cavities preferentially distributed at the interphase boundary could weaken interfacial cohesion and increase the material’s overall brittleness. Understanding how irradiation-induced He cavities form and grow in ductile-phase toughened tungsten is essential for developing robust plasma-facing component materials that can withstand the extreme environments of future fusion energy systems.

Summary

Ductile-phase toughened tungsten composites made of W, Ni, and Fe are promising candidates for use as plasma-facing components in fusion reactors for future clean energy systems. Understanding how irradiation defects form and distribute is essential for developing materials that can withstand energetic neutron bombardments and thermal shocks inside a fusion reactor without fracturing.

Researchers emulated fusion neutron irradiation in a W-Ni-Fe composite by irradiating the material with Ni+ and He+ ions at an elevated temperature. Transmission electron microscopy studies showed He-filled cavities throughout the material. There are a hundred times more He cavities in the W phase than in the NiFeW ductile phase, but the He cavities in the ductile phase are five times as large. The spatial distribution of the He cavities varied in the different sections of the composite. The cavities preferentially exist at the boundary between the pure W phase and the ductile phase. These cavities likely form through processes of diffusion, clustering, and trapping of both vacancies and He atoms in the material. The presence of the He cavities at the interphase boundary could weaken interfacial cohesion and increase the overall brittleness of the material.

PNNL Contacts

Wahyu Setyawan, Pacific Northwest National Laboratory, Wahyu.Setyawan@pnnl.gov

Weilin Jiang, Pacific Northwest National Laboratory, Weilin.Jiang@pnnl.gov

Funding

This research was supported by the Office of Fusion Energy Sciences under Contract DE-AC05-76RL01830. A portion of this research was performed using the Environmental Molecular Sciences Laboratory, a Department of Energy Office of Science user facility at Pacific Northwest National Laboratory.

Published: April 1, 2022

W. Jiang, D. Zhang, D. Li, J. Heo, Z. Wang, L. Zhang, N. Overman, T. Varga, Z. Hu, X. Wang, L. Shao, W. Setyawan, “Behavior of helium cavities in ion-irradiated W-Ni-Fe ductile-phase toughened tungsten,” Journal of Nuclear Materials, 561, 153565, (2022), [DOI: 10.1016/j.jnucmat.2022.153565]