Researching the Ocean Is More Difficult Than Studying Space

Technical Development with Nolann Williams

Nolann Williams

After a short period of time at the Pacific Northwest National Laboratory (PNNL)’s Marine and Coastal Research Laboratory (MCRL), Nolann Williams quickly realized that engineering for outer space applications—which deals with strange phenomena like tin whiskers, vacuum arcs, and the inability to retrieve projects once in orbit—was easier than marine engineering.

Meet Nolann Williams an electrical engineer who joined in June 2019 and has spent the past year supporting the Triton Initiative, which focuses on developing and testing environmental monitoring technology and methods to remove barriers associated to marine energy installations. Specifically, Williams’ contributions propelled technology development for companies awarded U.S. Department of Energy (DOE) funding. Supported by the DOE’s Water Power Technologies Office (WPTO) through the Triton Initiative, these projects provide important technical development for monitoring the environment around marine energy systems. But working on technology development for instruments deployed in marine environments isn’t easy—in fact, Williams claims marine engineering is more challenging than his work studying outer space!

Before joining PNNL, Williams worked for a start-up company in Southern California developing robots and computer interfaces. He came to MCRL to work on Triton’s marine energy environmental monitoring technology projects and serve a greater purpose by helping the world around him in new ways. The marine environment is dynamic in a multitude of ways: seawater exposure, pressure changes, underwater power and lighting, biofouling, weather dynamics, and the mechanical aspects of keeping electronics safe under water, have proven to be a real challenge. But like the celestial wonders that exist outside our terrestrial home, the ocean holds a great deal of promise for knowledge that can be discovered and harnessed for a sustainable future. Many look to outer space for inspiration, but researchers at PNNL’s Sequim Campus look off their dock for renewable energy potential in the ocean’s waves and tides.

Energy generated from waves and tides has a bright future, but currently, the technology and implementation come with a high burden and cost to developers. The lack of marine energy installations means there is little data to understand and address environmental effects and set achievable monitoring requirements. Therefore, challenges rest on the shoulders of regulators at the local, state, and federal levels, which require extensive testing and studies of environmental impacts, all to ensure marine energy technologies are sustainable and safe for marine life. Triton aims to make the implementation of marine energy devices possible by breaking down the barriers to installation; specifically, by supporting environmental monitoring technology development to improve performance and reduce costs of environmental monitoring. Williams’ efforts to support technology developers are vital to reaching that goal. The DOE awardees develop technologies that illuminate environmental impacts of marine energy devices. Williams works with these DOE awardees to make the electronics systems and interfaces of their technologies effective, reliable, user-friendly, and able to withstand harsh marine conditions.

Although he joined the Triton Initiative several years after the DOE projects began, Williams filled a key role in completing the technical development for many of these technologies. He supports three DOE-funded tasks including the BioSonics, Inc., Integral Consulting's benthic habitat mapping, and Woods Hole Oceanographic Institution’s electromagnetic field (WHOI EMF) detection projects. These projects have all undergone baseline field testing and are now benchmarking improvements before final testing occurs in 2021. Williams works directly with each of these companies to learn about their in-house technical goals and discuss options for capabilities they want to develop.

Williams’ collaboration with BioSonics, Inc. helped them characterize and reduce the impact of their perimeter detection system on marine life by reducing audible frequencies. Asa Packer, Lead Systems Engineer at BioSonics mentions “I wrote up a short description of the measurements we needed and Nolann ran with it. He performed all the tests in PNNL's anechoic chamber, and also in open water so we could compare the results. He even built a nice mounting rig for the transducers that he gave to us in case we need to perform similar testing in the future. It would have been very difficult for us to do all this testing at our facility, so it was great that Nolann was able to do it for us.” From testing the equipment in anechoic tanks at MCRL, to building a test rig to deploy the system off a boat in open water, Williams’ technical expertise enabled BioSonics, Inc. to see a dramatic reduction in frequencies audible to marine mammals and an increase in clean data outputs from their system.

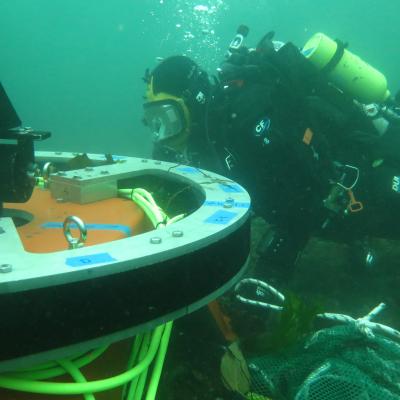

Integral Consulting’s benthic mapping project with sediment profile imaging (SPI) technology has consulted Williams about increasing the capabilities of the SPI system. Currently, Williams works with them to design a fully developed hydraulic system, which will allow deployment of their sediment imaging system’s prism to penetrate through harder substrates using water jets to fluidize sediments. To test the system, they put together a specification for a monitoring capability that would add live video and lighting to enable remote viewing of the system as it digs into the sediment. Williams’ work is centered on developing a USB camera, lighting controller, and an ethernet power link that could go to 100-meter depths. In collaboration with Integral Consulting and the original creator of the SPI technology, Williams will help make the instrument as resilient and versatile as possible. Ultimately, these efforts will bring them one step closer to creating a commercial system to image and study sediments that cannot currently be sampled with any other technology.

Lastly, the WHOI EMF detection team has crafted a highly sensitive research platform that ran into an unexpected hurdle during its initial testing phase. Like many scientists and engineers, Williams appreciates the bumps in research which often lead to further questions and technology solutions. While conducting tests at Sequim Bay the WHOI EMF system detected a local EMF source inside of the bay that was previously unknown. While this was considered an unfortunate obstacle to the sensor testing and development, Williams saw it as an opportunity. He pondered, "what is making that field and how common are they along shorelines?” While the solution to this unexpected variable has not yet been found, Williams used the opportunity to ask bigger questions about how power in marine environments is generated, and the types of signals that should be investigated to fully understand environmental impacts. As the answers to these questions are discovered, the PNNL Triton team is more aware of the local EMF sources and how these may impact future environmental monitoring tests.

For Williams, the best part of his job is asking questions and developing new systems. His work on the DOE projects, as well as the technical development effort for the Triton Field Trials (TFiT) EMF task, has allowed him to do just that. In TFiT’s effort to determine best practices for measuring EMF’s in marine environments, Williams helps manufacture technologies to do this best. “I love developing new systems from scratch… [and] taking a raw idea with all its sparkling promise, building up electrical systems, and coordinating with mechanical engineers to marry [those] capabilities into a machine greater than the sum of its parts,” says Williams.

You can expect a lot from Williams in the future. He will continue to serve Triton as a key player in supporting the DOE awardees and offer creative engineering solutions to the TFiT EMF task. In an upcoming project, he will also explore solutions for marine energy materials that are prone to failure, like seals and bearings. He and his colleague, Robert Jeters, will investigate poly-crystalline diamond as a material for bearings in marine energy systems. Discovering materials that are robust, resistant to corrosion, and potentially suitable for novel turbine designs without seals or mechanical linkages may enable highly efficient and mechanically simple marine energy generators to power future systems. Williams’ contributions to technical development have the potential to change the marine energy industry in powerful ways.

Now that Williams is getting acquainted with the idiosyncrasies of the marine environment and the trials of electrical engineering underwater, he looks forward to further addressing the diverse challenges of marine energy. He is motivated by finding solutions that give the industry momentum, and he loves working on the water—a winning combination for an engineer at a marine sciences lab. As Williams puts it, “it’s hard to beat time on a boat!”

Written by Cailene Gunn.

Subscribe to our monthly newsletter here.

Published: June 16, 2020