Have U.S. Natural Gas Pipelines Forged a Path for the Future of Hydrogen?

Researchers explore opportunities in shared infrastructure for the two gaseous fuels

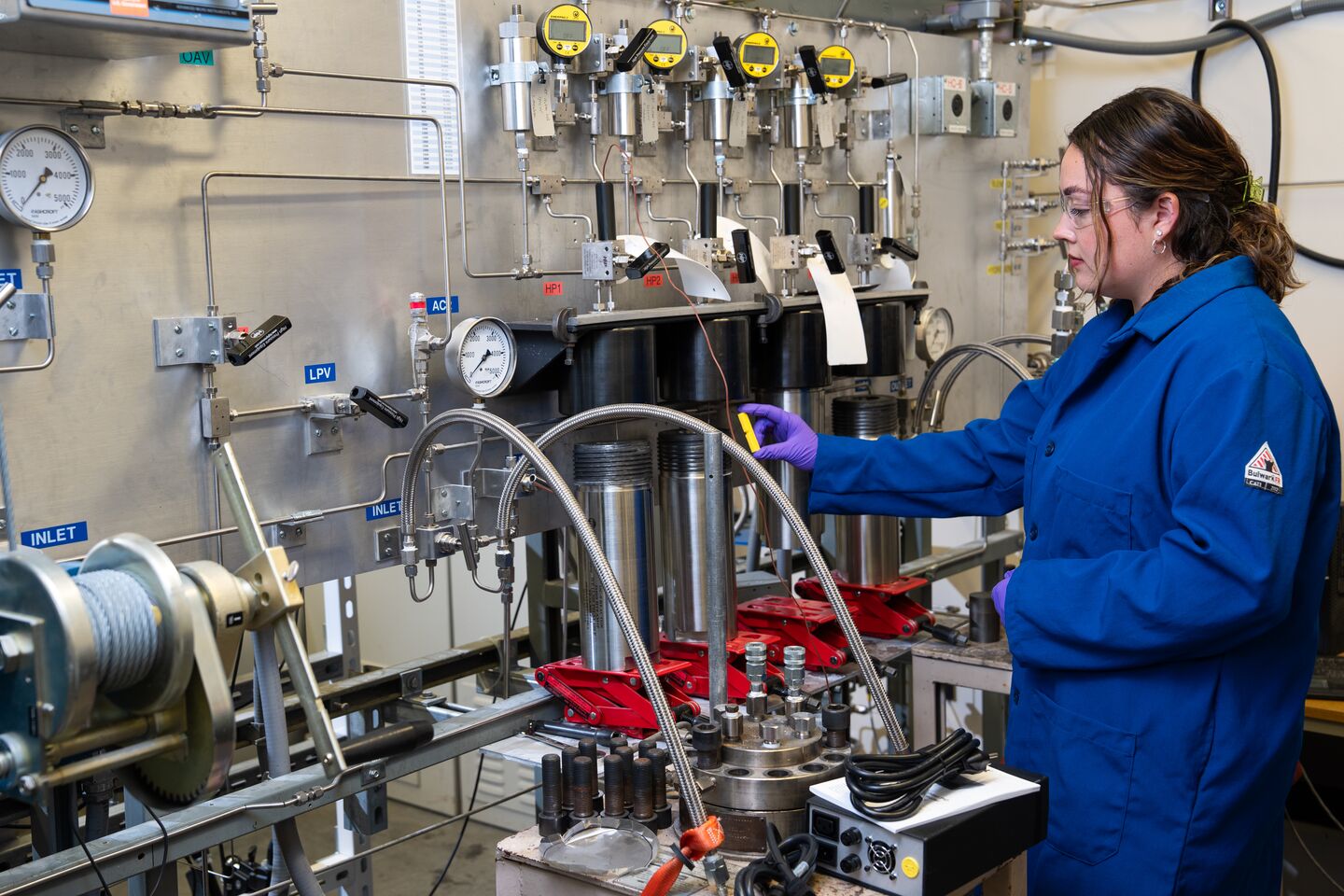

Kevin Simmons

(Photo by Andrea Starr | Pacific Northwest National Laboratory)

Over the course of a century, the natural gas industry has proven the effectiveness and convenience of its vast pipeline network. As the United States continues to explore opportunities in American-made hydrogen fuel for transportation and industry, researchers at the Department of Energy’s (DOE’s) Pacific Northwest National Laboratory (PNNL) are asking: how compatible, exactly, is hydrogen fuel with the existing natural gas pipeline network?

A staggering network

Transporting and storing enormous quantities of gaseous fuel across one of the world’s largest countries is no small feat. Millions of miles of natural gas transmission and distribution pipelines stretch across the United States; it has been painstakingly built, maintained, and renovated across the last hundred years.

It’s tempting to assume that hydrogen (which, like natural gas, is a gaseous fuel that can be cooled to a liquid form) could use the same pipelines. But hydrogen fuel is a different molecule compared to natural gas and those differences could lead to significantly different behavior in pipelines over their expected lifetimes.

Researchers are also studying blends of hydrogen and natural gas, which could help drive down costs for consumers while using existing natural gas transmission and distribution infrastructure. But these blends might behave differently from natural gas, and even differently from pure hydrogen.

Neither hydrogen, nor hydrogen blends have been tested extensively in the wide array of materials used for natural gas transport and storage—until now.

A complicated landscape

Plastic pervades the natural gas infrastructure in the United States. From the distribution pipelines that run through neighborhoods to housings for valves and joints in metal transmission pipelines, these pipelines and components are commonly made of medium-density and high-density polyethylene (MDPE and HDPE)—plastics that have been used for gas distribution for many decades. However, they have not yet been used for hydrogen distribution. So the question is: how do they respond to hydrogen fuel?

“We’re looking at the effects of hydrogen and blended hydrogen-natural gas mixtures on those materials from a short-term perspective as well as a long-term perspective,” explained Kevin Simmons, chief materials scientist at PNNL. “If we add hydrogen to a system, is there any effect in reducing the long-term performance of that material?”

The answer, as it turns out, is far from straightforward. MDPE and HDPE might sound like just two materials, but it’s actually a wide array of different compositions.

“Often, people think polyethylene is just polyethylene. But every chemical manufacturer has their own way of making it,” Simmons said. Polyethylene is named for its backbone of ethylene molecules, but specific compositions can vary significantly based on the different compositions of shorter and longer chemical chains that branch off from the backbone. Furthermore, many polyethylene manufacturers have changed their compositions in significant ways over the many decades it took to build out the existing natural gas infrastructure.

Surprising results

PNNL is uniquely equipped to test these gas pipeline materials under real-world operating conditions. The Laboratory's extensive suite of materials testing and analysis tools—many of which are exclusive to PNNL within DOE—include advanced cryogenic testing (as low as 4 Kelvin/-450°F) and pressurized solid-state nuclear magnetic resonance to observe changes in material structure at the molecular level.

To study interactions between pipeline materials and hydrogen, PNNL researchers tested hydrogen (as well as hydrogen blends) in both test piping and in a specially pressurized slow crack growth environmental test chamber. They discovered that the time it took to depressurize the test piping for analysis drastically affected a key measurement: crystallinity.

Higher crystallinity can correlate to more brittle pipelines, while lower crystallinity can indicate a more resilient material. When tested more than an hour after depressurization, the measurements seemed to show that adding hydrogen had increased the polyethylene’s crystallinity in some materials.

Then, the researchers used a specially pressurized environment to recreate the conditions of an operational pipeline, allowing them to test the material without a delay. They found that the added hydrogen actually reduced the crystallinity of the pipeline material.

“We discovered that there’s really a time sensitivity to the material,” Simmons said.

Now, using samples of a wide range of common distribution pipeline polyethylene compositions and robust experimental procedures, Simmons and his colleagues are building advanced models to represent how hydrogen and hydrogen-natural gas blends affect those materials differently than natural gas. And the results are largely promising, with the most common pipeline materials showing similar performance.

“Depending on the particular polyethylene’s chemical composition, the performance with hydrogen and hydrogen blends can vary,” Simmons said. In some cases, the results are surprising: one type of HDPE showed improved performance with pure hydrogen, but diminished performance with hydrogen blends.

“It’s not as though any materials would ‘go bad’ right away, but you might learn that certain materials need to be replaced more—or less—often,” Simmons said. “This type of analysis is crucial as we explore use cases for hydrogen fuel.”

One of the team’s papers on this work was selected as the Outstanding Technical Paper for the American Society of Mechanical Engineers 2024 Pressure Vessels & Piping Conference.

This research was supported by the Department of Energy, Office of Energy Efficiency and Renewable Energy’s Hydrogen and Fuel Cells Technologies Office.

Published: September 5, 2025