PNNL Innovators Elected to the National Academy of Inventors

Zhiqun (Daniel) Deng and Yehia Ibrahim join the 2025 class of NAI Fellows

Zhiqun (Daniel) Deng and Yehia Ibrahim are the latest inventors from Pacific Northwest National Laboratory to be elected to the National Academy of Inventors.

(Composite image by Shannon Colson | Pacific Northwest National Laboratory)

The National Academy of Inventors (NAI) has elected two innovators from Pacific Northwest National Laboratory (PNNL) into its 2025 Class of NAI Fellows.

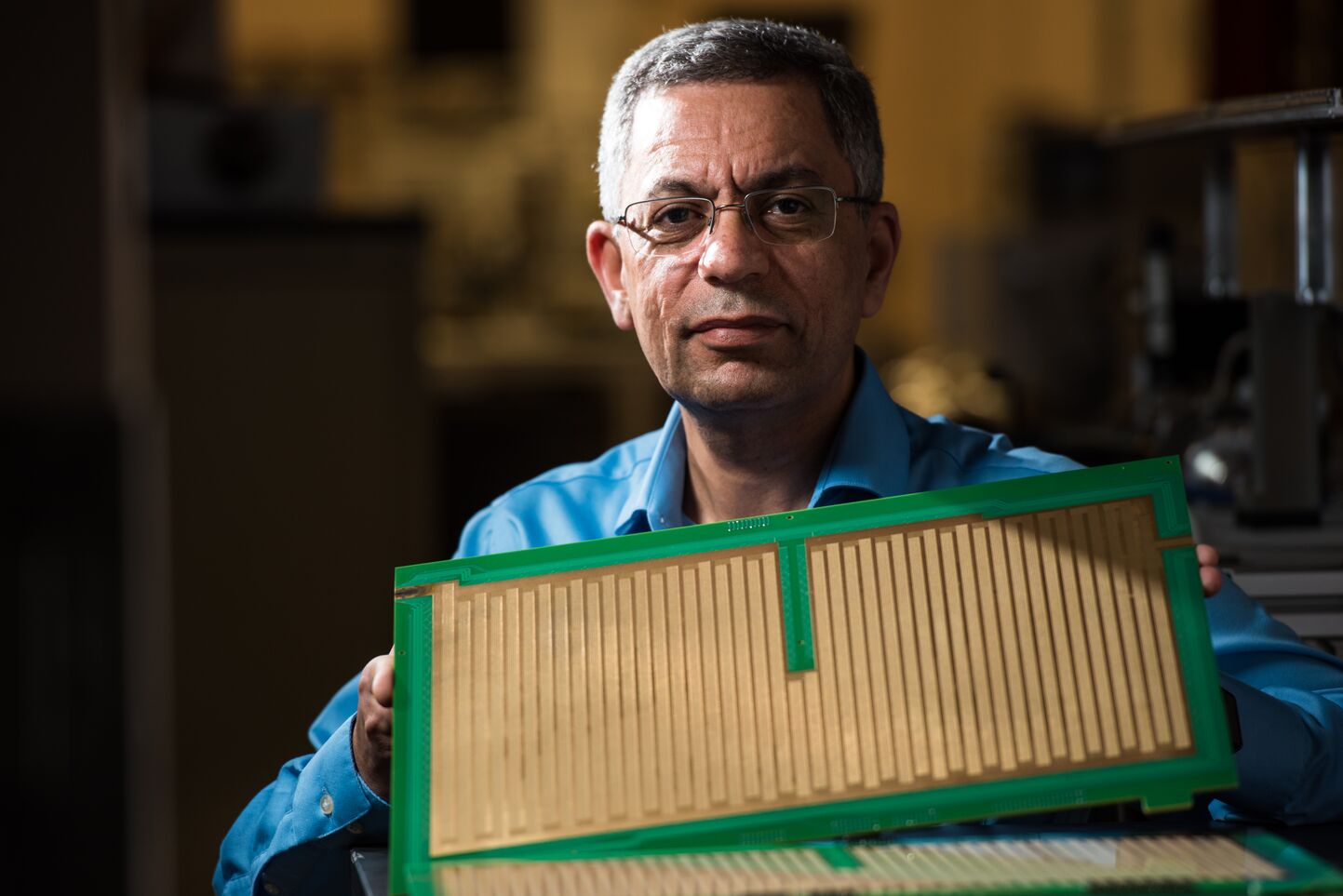

Yehia Ibrahim, who leads the Translational Omics group at PNNL, created multiple devices that improved the speed and sensitivity of analytical tools used in biochemistry, biomedicine, and predictive phenomics. His ion mobility separations technologies have enabled the separation of biomolecules at previously unseen resolutions, allowing for ultra-sensitive screening and detection of molecules.

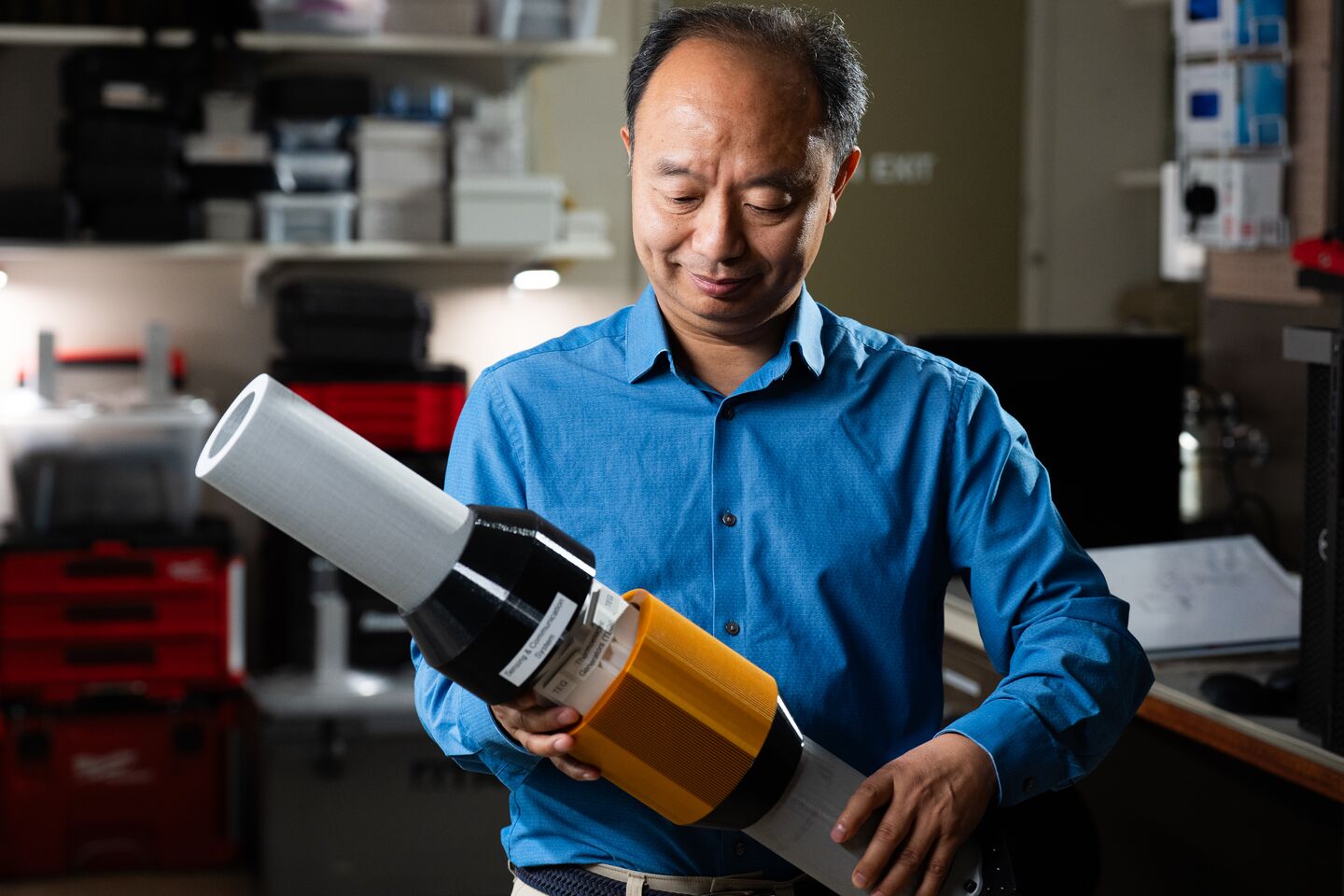

Laboratory Fellow Zhiqun (Daniel) Deng leads PNNL’s Bio-Acoustics and Flow Laboratory, which develops solutions to a range of grand challenges at the intersection of energy and ecology. He was recognized for inventing a range of sensors, remote data-gathering technologies, and energy harvesting technologies that support energy innovation.

Both inventors credit PNNL’s culture of innovation, risk-taking, and understanding industry needs with their ability to be such prolific inventors over many years.

“Working closely with our commercialization managers, we understand clearly what industry is lacking and what the field needs in line with what our sponsors need,” said Ibrahim. “Having all of this expertise in-house provides an ideal environment for innovation.”

The NAI has celebrated the achievements of outstanding inventors since its inception in 2010. Election into the NAI Fellows is considered one of the highest honors for inventors to achieve. With over 130 R&D100 awards, PNNL inventors are consistently recognized for their innovative technologies.

Creating a big impact with tiny ions

Ibrahim’s drive to innovate began long before he became a scientist. Though he remembers his out-of-the-box thinking in middle school, it was his high school physics teacher who really sparked his interest in inventions.

“I was fascinated by physics,” said Ibrahim. “We were studying cathode rays and how the old TVs used to work, with these big bulky devices. I wanted to figure out how to improve the technology and make it more compact. Though my ideas at the time were unrealistic, I was fascinated by the idea of making things better.”

Ibrahim’s spark to improve technologies was reignited at Virginia Commonwealth University, where he studied physical chemistry for his PhD. There, he met Nobel Laureate John Fenn, whose work in ionization—the process of forming charged particles—intrigued him. Driven to combine his interest in ionization with his desire to innovate, Ibrahim pursued a postdoctoral fellowship at PNNL under the mentorship of the prolific inventor, Richard Smith.

“The culture of Smith’s team at the time was to encourage everyone to innovate,” said Ibrahim. “We were doing the fundamental research, but at the same time, we were able to recognize when we had something new here, when we created something that could benefit others beyond just us.”

Together, Ibrahim, Smith, and colleagues created multiple devices that improved the separation of ions in chemical mixtures used in biochemistry and biomedicine.

“Separating chemicals is kind of like running a race,” Ibrahim said. “The farther the chemicals travel, the more the ‘fast’ chemicals can separate from the ‘slow’ ones.”

Ibrahim and his team set out to increase the “running” distance without creating a gigantic machine. They co-invented the Structures of Lossless Ion Manipulations, or SLIM, device, which features a winding path that allows for greater separation in a more compact device. SLIM increased the ion mobility resolving power to 1,000 (approximately 10 times more than conventional methods).

“Getting the ions to move around corners was the biggest challenge,” said Ibrahim.

The powerful resolution and compact design of SLIM make it perfect for pairing with analytical sensors in the field, with applications ranging from the study of metabolism-related molecules to explosives detection.

Since joining PNNL, Ibrahim has been awarded 36 U.S. patents and 56 foreign patents on different ion separation devices, from improving the ion funnel trap to developing the All Pressure Ion Confinement (APIC) technology. His work earned him R&D100 awards in 2013 and 2017, and a Federal Laboratory Consortium award in 2018. He was named PNNL’s Inventor of the Year in 2019. Currently, Ibrahim co-directs the Pacific Northwest Advanced Compound Identification Core at PNNL.

Despite his many accolades, Ibrahim’s journey as an inventor is far from over.

“We want to create a device with even greater resolution—we’re aiming for 10,000 resolving power,” Ibrahim said. “I want to push the boundaries of what’s feasible into what can be done.”

Driven by energy innovation

Deng was trained to innovate at the University of Illinois at Urbana-Champaign and Tianjin University. Coming to PNNL, however, inspired Deng in a different way: to solve problems with national impact.

“What really motivates me is to be the first one to invent something that has a meaningful impact on society,” Deng said. “That motivation, coupled with the culture we have at PNNL, drives my team and me to tackle these grand challenges with innovation.”

Deng credits his mentors and colleagues for laying the groundwork. At PNNL, Deng built a multidisciplinary team—including mechanical engineers, materials scientists, chemists, mathematicians, battery engineers, electrical engineers, and biologists—to develop and test a variety of sensing solutions.

One such solution is the Radio-Frequency Transmitter for Detecting and 3-D Tracking Wildlife, which provides information about how small flying animals respond to certain types of energy infrastructure. The tiny-yet-mighty transmitter could be implanted into the smallest specimen with a longer range than commercially available transmitters. This technology has also been instrumental in tracking and combating invasive Asian hornets in the United States and other countries, averting potentially devastating outcomes for agriculture and public health.

“Beyond energy innovation, I’m deeply passionate about how these innovations interact with the natural world,” Deng said. “I feel so fortunate to be able to unite both through teamwork.”

Deng and his team have also created many other animal tracking devices. For example, the Lab-on-a-Fish device—the world's first biosensor that combines local data processing with wireless sensing of real-world fish physiology, location, and environmental conditions—monitors the health and behavior of fish passing through hydropower dams.

Though many of Deng’s animal-tracking technologies were named after the animals they were meant to track, some of them have been used to track a variety of other species.

“We created the Shad Acoustic Tag because we wanted to study juvenile American shad—a small, delicate fish that is incredibly difficult to tag,” said Deng. “The device is now being used to study other species, like delta smelt, invasive sea lamprey, and Asian carp. Some assumed the name implied a narrow focus, but it didn’t—we were simply targeting a specific application when we began the development.”

Deng’s work goes beyond animal tracking. His inventions include a sensor that listens for signs of trouble inside flow batteries, tiny batteries for powering small electrical devices, autonomous sensing device for hydropower systems, an ocean buoy that powers itself by capturing wave motion, a fast-response sensor that detects refrigerant leaks, and a self-powered system for sensing and sending data from underground environments.

Since arriving at PNNL as a postdoctoral researcher, Deng has been issued 23 patents and received multiple awards for his work, including R&D100 awards in 2021 and 2025, a Federal Laboratory Consortium award in 2020, and the Fish Passage Career Achievement Award in 2025. He was named PNNL’s Inventor of the Year in 2022 and a Distinguished Inventor of Battelle in 2024. He is a member of the Washington State Academy of Sciences and a Fellow of the American Society of Mechanical Engineers.

Like Ibrahim, Deng is far from being done as an inventor.

“We need to keep challenging ourselves and always have a goal to reach a higher level of innovation with more meaningful societal impact,” Deng said. “This is just the beginning.”

Cultivating an ecosystem of innovation

The success of PNNL’s inventors would not be possible without the strong support of sponsors and leadership. Christina Lomasney, Director of Commercialization, Technology, Deployment and Outreach, fosters PNNL’s culture of innovation through the Office of Collaboration and Commercialization (OCC).

“Our OCC team engages with researchers through every step of the technology transfer process, from intellectual property protection and maturation to industry collaboration and technology commercialization,” Lomasney said.

“Innovation is really a collective effort,” said Deng. “Not just with our research team, industry and academic collaborators, and commercialization managers, but our sponsors who trusted us even when we hit obstactles and continued to support us.”

Deng acknowledged the Energy I-Corps program, an initiative of the Department of Energy (DOE), Office of Technology Commercialization, for providing him with training to understand the market needs and potential impact.

Entrepreneurial and industry training opportunities, like the Energy I-Corps program, are crucial to helping scientists get the credit they deserve for their inventions. Ibrahim reflected upon a time when he missed out on his opportunity to obtain an international patent because he publicly disclosed his invention at a conference before filing the patent.

“That incident taught me two important lessons,” said Ibrahim. “One, be courageous and open when you feel you’ve created something novel that can have impact. And two, always reach out to your commercialization manager first!”

Ibrahim’s work is sponsored by the DOE Office of Science's Biological and Environmental Research program, the National Institute of General Medical Sciences, and the National Cancer Institute. Part of his research was performed at the Environmental Molecular Sciences Laboratory, a DOE Office of Science user facility located at PNNL.

Deng’s work is sponsored by multiple DOE offices including the offices of Critical Minerals and Energy Innovation and Hydrocarbons and Geothermal Energy and by the U.S. Army Corps of Engineers.

Published: December 17, 2025