New Capabilities in Fusion Energy Sciences

PNNL scientists developed capabilities to study materials for fusion reactors

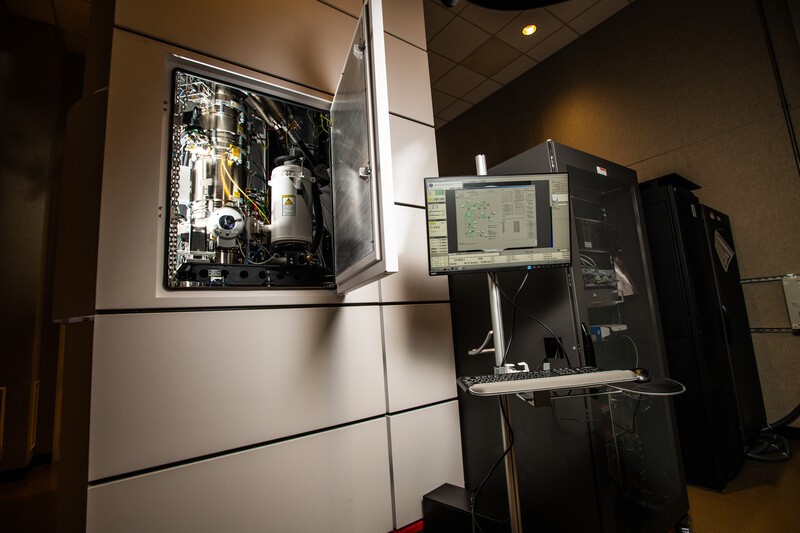

Materials Scientist Ramprashad Prabhakaran shows off the high temperature mechanical testing capabilities at Pacific Northwest National Laboratory.

(Photo by Andrea Starr | Pacific Northwest National Laboratory)

The most powerful energy source in the universe—the sun—is powered by nuclear fusion. Though fusion energy has enormous potential, scientists have not yet been able to harness its power. However, researchers at Pacific Northwest National Laboratory (PNNL) are bringing us one step closer by developing instrumentation to study materials that may be used in fusion reactors.

The most studied fusion reaction involves the fusion of two hydrogen isotopes—deuterium and tritium—to form helium and a neutron. This reaction occurs at very high temperatures—much hotter than most metals can tolerate. Materials Scientist Ramprashad Prabhakaran established a system capable of testing the mechanical properties of materials at elevated temperatures. This system includes a furnace that can reach temperatures over 1200°C and an elemental control element that can pump Argon into the furnace to create an oxygen-free environment.

“Very few materials can withstand the extreme environment inside fusion reactors,” said Prabhakaran. “Ceramics are too brittle at high temperatures and most metals melt.”

Prabhakaran is currently exploring different tungsten-based alloys as materials for fusion reactors. Though tungsten has one of the highest melting points of any element, it is prone to fracturing under stress. By mixing tungsten with other metals, scientists can increase the ductility of the material. “The key is finding the right mixture of metals and tungsten,” said Prabhakaran.

Heat isn’t the only challenge reactor materials face. Energetic neutrons and helium ions, products of the fusion reaction, bombard the reactor walls and lodge themselves into the material. Formation of gas bubbles from the implanted helium and transmutation can make the reactor materials more brittle and likely to fracture. Scientist Weilin Jiang teamed up with Materials Scientist Libor Kovarik to visualize the formation of helium bubbles within tungsten alloys. They use a novel technique called monochromated aberration corrected scanning transmission electron microscope (MACSTEM) to see how bubbles penetrate into alloys. Though traditional STEM techniques only allow bubbles and atoms on the surface of the material, Jiang and Kovarik’s method lets them see inside the material itself.

Jiang, Kovarik, and other researchers at PNNL use an ion irradiation method to emulate the fusion environment and predict material performance. “Though we may not see it with our eyes, the microstructure of materials evolves over time when exposed to extreme conditions, like those in fusion reactors,” said Jiang. “Those changes will degrade the material properties, including mechanical strength and thermal conductivity.”

These experiments can help scientists understand the mechanisms for the property degradation and inform the design of future materials for fusion reactors.

Published: June 1, 2022