Mapping the Assembly of Hybrid Materials

New collaboration applies PNNL expertise in 3D microscopy to hybrid biomaterials

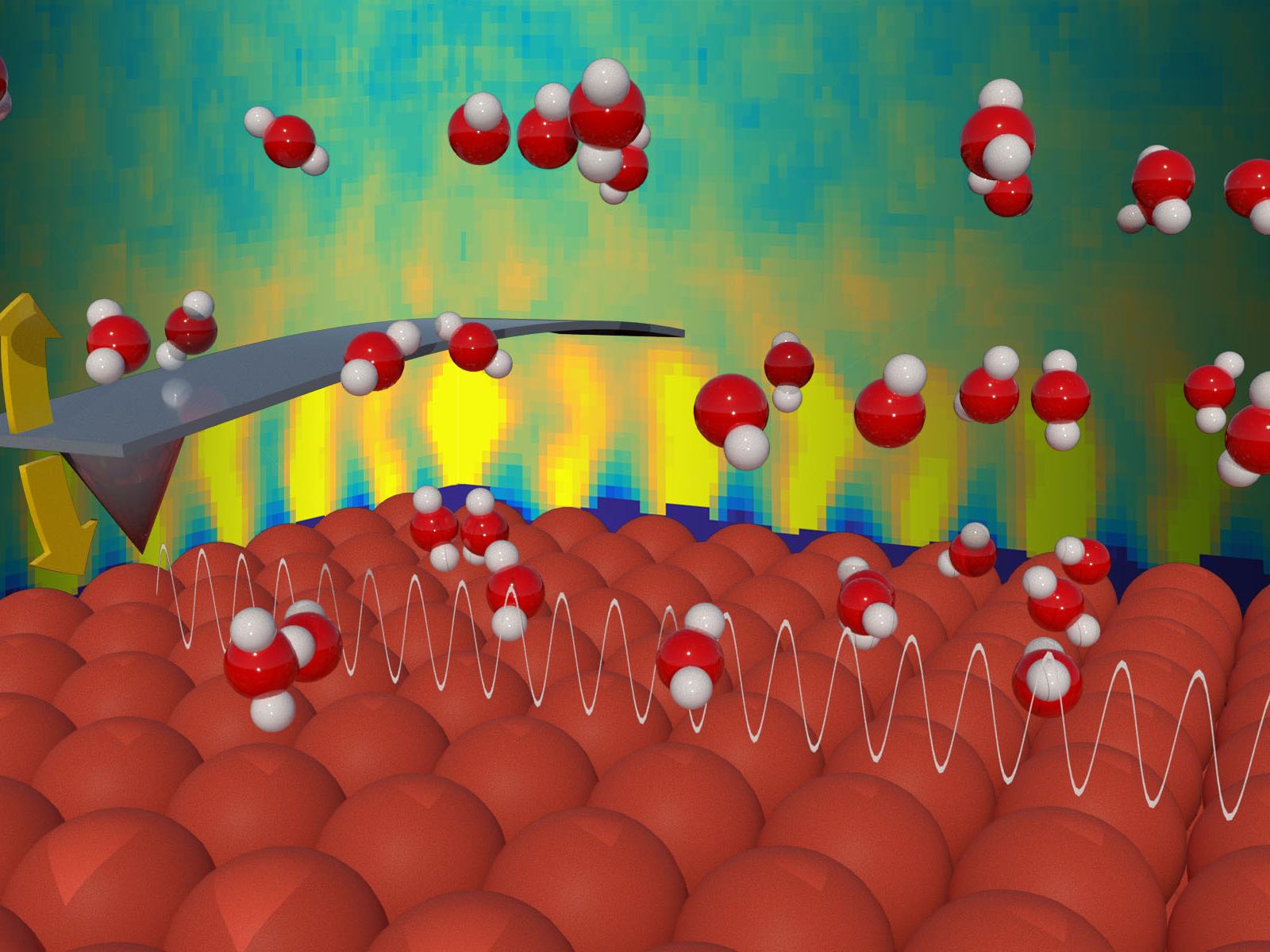

3D atomic force microscopy allows researchers to gather information about interfaces with atomic precision.

(Illustration by Nathan Johnson | Pacific Northwest National Laboratory)

In biological systems, complex materials assemble through processes tuned over thousands of years. Scientists are trying to develop a similar level of control on a much shorter timescale. To accomplish this goal, researchers must understand the very beginnings of material formation and assembly.

A collaborative project between Cornell University and Pacific Northwest National Laboratory (PNNL) is studying how hybrid materials, with biological and inorganic components, form at the earliest stages. The team is specifically focusing on what happens where liquids and solids meet, a crucial interface. They plan to use these fundamental discoveries to develop some overarching guidance on using synthesis to control the final structure of hybrid materials.

“I’m excited for the future of this research,” said Elias Nakouzi, a PNNL materials scientist. “We’re teaming up with a group of people who are some of the top experts in the field of biomaterials synthesis and assembly. I think we can make some really impactful fundamental discoveries together.”

The researchers will design polymer surfaces with nano-patterned chemistries. These surfaces will act as templates to control how inorganic crystals nucleate, grow, and assemble. By understanding how the inorganic and organic components interact, the team will develop pathways for synthesizing hybrid materials that mimic naturally occurring biominerals. The researchers will also explore an alternative approach to creating hybrid materials. In this path, they will start with the inorganic crystals and establish how the polymers interact and incorporate during crystal growth.

The project takes these approaches across three different model systems at a range of scales. This allows the researchers to identify different ways to tune growing hybrid systems throughout the assembly process. Accomplishing these goals requires combining new synthesis methods with advanced characterization techniques. That’s where Nakouzi and PNNL come in.

Visualizing interfaces to understand materials

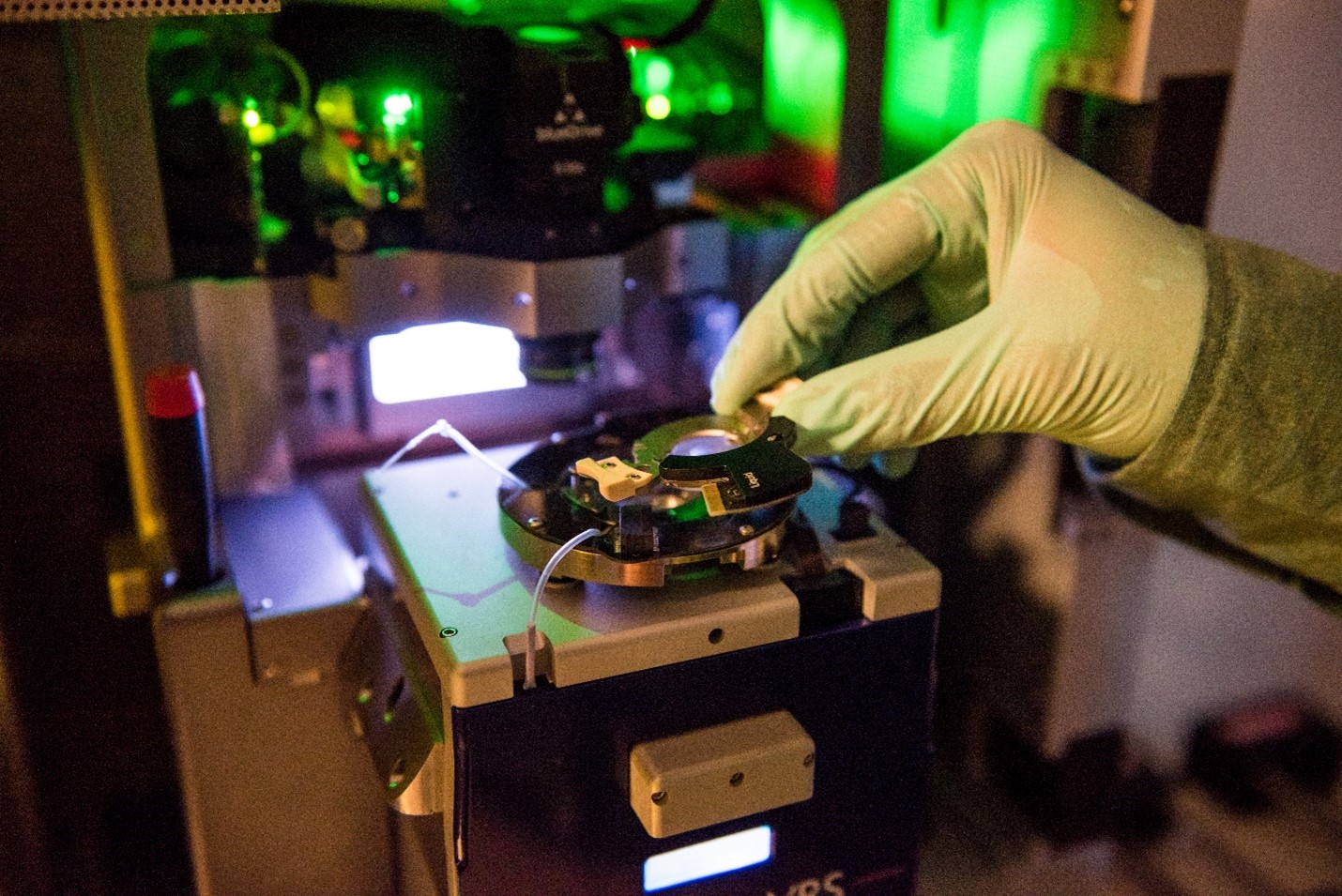

Nakouzi brings his expertise with 3D atomic force microscopy (3D AFM) to the project. In 3D AFM, researchers use a nanosized probe to study the molecular forces at liquid-solid interfaces. The instrument creates a 3D force map that is directly related to the distribution of molecules, giving scientists a detailed view of the interface.

3D AFM is a highly specialized technique—PNNL has one of few setups in the world. Nakouzi led the development of this capability as part of his Linus Pauling Postdoctoral Fellowship at PNNL. He developed this capability under the Materials Synthesis and Simulation Across Scales (MS3) Initiative, supported by the Laboratory Directed Research and Development (LDRD) program. Nakouzi then demonstrated its impact while working on the Basic Energy Sciences Synthesis and Processing core program, and the Interfacial Dynamics in Radioactive Environments and Materials (IDREAM) Energy Frontier Research Center.

“I think our 3D AFM work represents a highly successful aspect of the LDRD program,” said Nakouzi. “PNNL invested in the risky development process. Now, it’s paying off with impact. We’re seeing more people interested in collaboration, using our skills to answer challenging science questions.”

Why is 3D AFM so useful? There are very few techniques that can provide molecular level detail of solid-liquid interfaces. In addition to being essential in the formation of hybrid nanomaterials, solid-liquid interfaces play a crucial role in a wide range of applications.

Nakouzi is part of the IDREAM Energy Frontier Research Center. His IDREAM work uses 3D AFM to study the layers of water on the surface of boehmite, an aluminum-based mineral found in industrial and radioactive waste. Understanding the interactions between the boehmite surface and water enables researchers to better predict how the boehmite aggregates—this is important because the size and shape of boehmite aggregates affects how legacy radioactive waste behaves.

3D AFM plays an important role in several other PNNL projects. Researchers are using the capability to understand how particles attach and aggregate, which are important problems in the context of materials synthesis, geochemistry, and environmental management. Identifying how particles attach and aggregate can help researchers develop better routes to complex materials and more effective methods of waste processing. 3D AFM provides the molecular level detail necessary to distinguish between different atomic pathways.

“It’s exciting to see the growth in our 3D AFM work,” said Nakouzi. “I think more people are starting to see how useful it can be. The more we learn about interfaces, the clearer it is that they play a massive role in all sorts of chemical processes.”

The new work will be funded by the Department of Energy Office of Science, Basic Energy Sciences, Materials Sciences and Engineering Division, Biomolecular Materials Program.

Published: December 19, 2023