Low-Temperature Upcycling of Polyolefins into Liquid Alkanes

A new system can convert common plastics into valuable fuel molecules

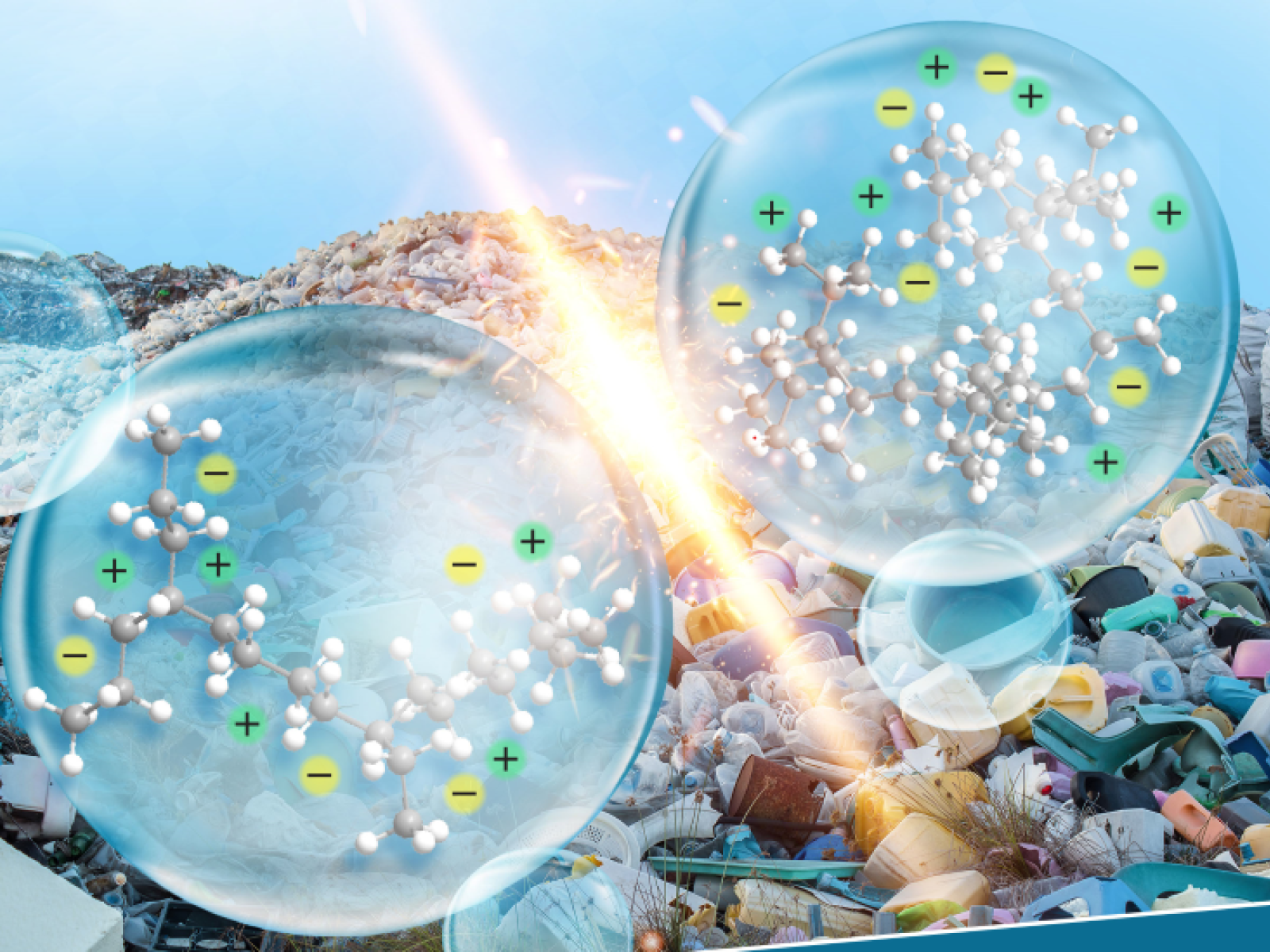

A combined reaction enables low-temperature conversion of a common class of plastics to valuable fuels.

(Image by Nathan Johnson | Pacific Northwest National Laboratory)

The Science

The massive quantity of single-use plastics produced and discarded every year represents a major challenge to sustainability. These plastics take valuable carbon and add it to landfills as waste, removing it from use. A new approach uses an ionic liquid catalyst to convert polyolefins, a common type of plastic, into valuable isoalkanes. The system combines the energy produced by alkylation with the energy required for the C–C bond breaking reaction. This allows polyethylene and polypropylene to be fully converted to liquid isoalkanes at 70 °C or below. The new reactivity may help researchers extract carbon from waste products, keeping it in play.

The Impact

An important aspect of closing the carbon cycle is reusing carbon that is already active in the economy. Currently, the carbon contained in many plastics is lost after a single use. This new approach allows researchers to convert a key type of plastic waste into carbon-based fuels, extending the usable life of carbon. The reactions can proceed at low temperatures under 70 °C, a dramatic decrease from the hundreds of degrees required for previous upcycling attempts. Implementing the process described here could help reduce plastic waste and lead to a more sustainable future.

Summary

The annual global production of over 360 million tonnes of plastics results in vast quantities of plastic accumulating in landfills and water bodies. Polyolefins, which make up over half of all plastics, are chemically inert and challenging to convert below their melting/softening point. The relatively high temperatures required to cleave the C–C bonds at reasonably high rates have hampered selective upcycling of polyolefin waste. Researchers developed a new, distinct approach that uses ionic liquids to increase polymer reactivity and combine the endothermic cleavage of the polymer’s C–C bonds with the exothermic alkylation of the cracking products. This enables full conversion of polyethylene and polypropylene to liquid isoalkanes below 70 °C. A Lewis acidic species generated in a chloroaluminate ionic liquid catalyzes both reactions. This process can convert unprocessed post-consumer items to high-quality liquid alkanes in high yields. The next steps in this research are to understand the mechanistic details of this new chemistry and generalize the types of polymers this process can convert to valuable products.

Funding

This work (J.A.L., O.Y.G., J.H., S.K., D.M.C., and L.H.) was supported by the Department of Energy, Office of Science, Basic Energy Sciences program, Division of Chemical Sciences, Geosciences and Biosciences (Towards a polyolefin-based refinery: understanding and controlling the critical reaction steps, FWP 78459).

Published: February 23, 2023

Zhang, W., Kim, S., Wahl, L., Khare, R., Hale, L. Hu, J., Camaioni, D.M., Gutiérrez, O.Y. Liu, Y., Lercher, J.A. 2023. “Low-temperature upcycling of polyolefins into liquid alkanes via tandem cracking-alkylation,” Science, 379, 807–811. [DOI: 10.1126/science.ade7485]