Autonomous Synthesis for Redox Flow Batteries

Combining robotics and flexible-batch decision algorithms to accelerate high-throughput experiments

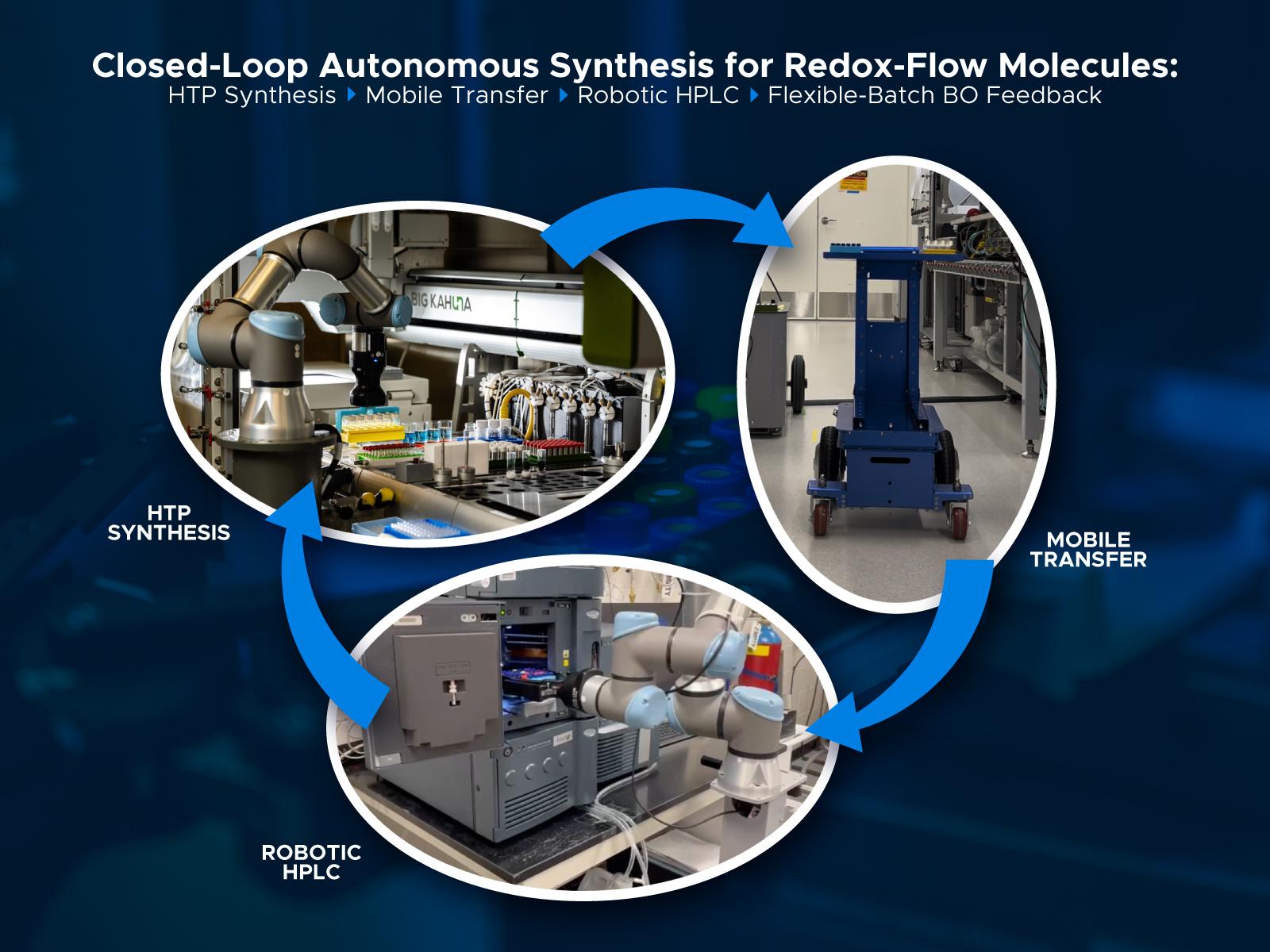

An autonomous loop executes high-throughput synthesis, performs analysis, and proposes the next experiments to accelerate science.

(Image by Derek Munson | Pacific Northwest National Laboratory)

Chemical reactions are complicated, with lots of different variables that can be tuned during an optimization process. Given the vast number of possible combinations, researchers have turned to high-throughput experimentation combined with robotics and machine learning to accelerate discovery. However, standard decision-making frameworks are often incompatible with batching and instrument constraints in high-throughput experimentation.

Researchers from Pacific Northwest National Laboratory (PNNL) and the University of Washington designed an autonomous experimental workflow to optimize the synthesis of fluorenone derivatives, a key component of redox flow batteries.

The synthesis stage included two steps—initial formulation followed by temperature-batched heating. After synthesis, a mobile robot transferred the sealed samples to a cobot-operated instrument for analysis. Having multiple, separate steps performed in different pieces of equipment meant that the decision-making and sampling strategies had to be flexible to work with the per-step batch sizes and equipment constraints. Their computational approach leveraged flexible-batch Bayesian optimization (BBO), an active learning method that can suggest multiple paths per experimental round—key for high-throughput experimentation.

The team designed and tested three different BBO frameworks that flexibly work with the different sample sizes in each step of the process. Combining the BBO frameworks with the robotic platforms available at PNNL enabled the researchers to test a wide range of synthesis conditions.

By iteratively varying reactant concentrations, reaction time, and temperature, the researchers found 11 conditions that produced over 90 percent yields of the fluorenone product at relatively mild temperatures. They accomplished this in three rounds of experiments, each testing a different BBO model. Using a more traditional experimental method, exploring all the reaction options would have required around 15 years of continuous data collection (6,655 rounds at 17–20 hours/round).

This work demonstrates an approach to tailoring software to work with more complex, multi-step, instrument-constrained processes and highlights the role that BBO approaches can play in decision-making on constrained hardware systems.

The PNNL team included Heather Job, Wei Wang, and Yangang Liang. The University of Washington team included Clara Tamura, Henry Chang, and Shijing Sun, now at the University of Cambridge. This work was partially supported as part of the Energy Storage Research Alliance (ESRA), an Energy Innovation Hub funded by the Department of Energy, Office of Science, Basic Energy Sciences program, under FWP 82132.

Published: September 30, 2025