Artificial Intelligence Tools for Advanced Manufacturing (AI4AM)

PI: Henry Kvinge

Objective

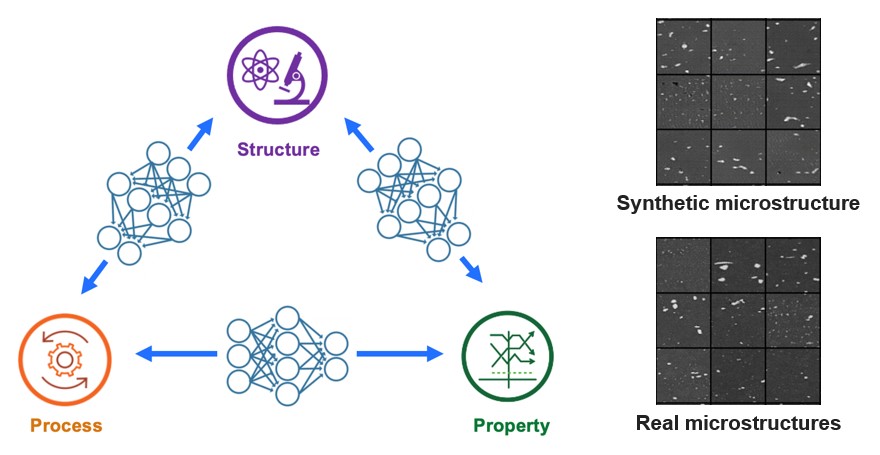

Develop trustworthy artificial intelligence tools that make the process of material discovery faster and more efficient, including:

- generative machine learning (ML) for materials design

- generative ML for material microstructure prediction

- explainability methods that query whether a model is using scientifically grounded concepts when making predictions

Overview

Advances in materials science can help address many of the critical challenges facing the modern world, from improved energy efficiency to increased compute capacity. As in many other scientific domains, methods from artificial intelligence and machine learning (AI/ML) promise to accelerate research and progress in this field. Unfortunately, the most recent advances in AI/ML (e.g., deep learning) have only recently started affecting advanced manufacturing, where classical methods still dominate. The purpose of AI4AM is to leverage mathematical frameworks to develop ML solutions to a range of advanced manufacturing problems. This includes working across a wide range of modalities, from images to time series to tabular data. Our goal is to advance ML by bringing in techniques from topology, algebra, and geometry to find more effective ways of representing data, framing learning problems, and extracting features.

The initial manufacturing process that we targeted was Shear Assisted Processing and Extrusion (ShAPE), a solid phase processing method developed at Pacific Northwest National Laboratory. We focused on Aluminum 7075, a material for which a substantial number of ShAPE experiments already exist. Despite this initial concentration on ShAPE, the project’s goal has always been to match problems in materials science and advanced manufacturing with novel ML tools and methods. Thus, the tools that AI4AM has produced have been largely manufacturing process/material agnostic or at least flexible enough to be transferred to other settings without extensive modification. The number of tools developed on AI4AM that are now being used on different projects with different materials or different manufacturing processes confirms our success in this regard.

In 2023 our team shifted to examining Topological Materials of interest to future computing, energy, and sensing applications.

Impact

- In the absence of first-principles modeling, the R&D cycle in advanced manufacturing is largely driven by ad hoc trial and error.

- By developing data-driven approaches, we can reduce the number of experiments required to find process parameters that generate a material with desired properties.

- Through our explainability tools that incorporate domain relevant concepts, we build user confidence in our models and quickly catch cases where our models are wrong.

Publications and Presentations

- Godfrey C.W., D.R. Brown, T.H. Emerson, and H.J. Kvinge. 2022. "On the Symmetries of Deep Learning Models and their Internal Representations." In Thirty-fifth Conference on Neural Information Processing Systems. doi:10.48550/arXiv.2205.14258

- Courts, Nico, and Henry Kvinge. "Bundle Networks: Fiber Bundles, Local Trivializations, and a Generative Approach to Exploring Many-to-one Maps." International Conference on Learning Representations. 2021.

- Howland, Scott, et al. “Parameters, Properties, and Process: Conditional Neural Generation of Realistic SEM Imagery Toward ML-Assisted Advanced Manufacturing.” Integrating Materials and Manufacturing Innovation 12.1 (2023): 1-10.