Featured Stories

December 9, 2025

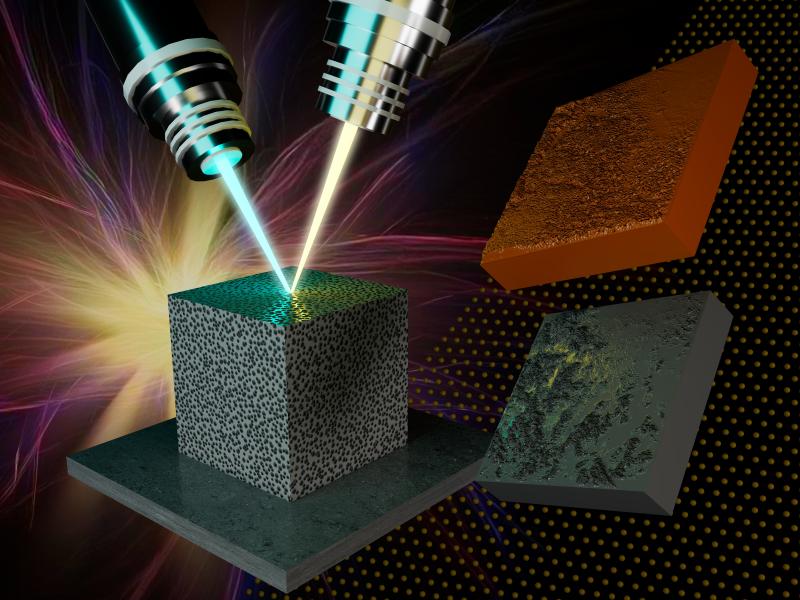

First Testing of Grid-Scale Battery Technology Begins at the Grid Storage Launchpad

December 4, 2025

Department of Energy, PNNL Partner to Power the Nation’s Bioeconomy

December 11, 2025

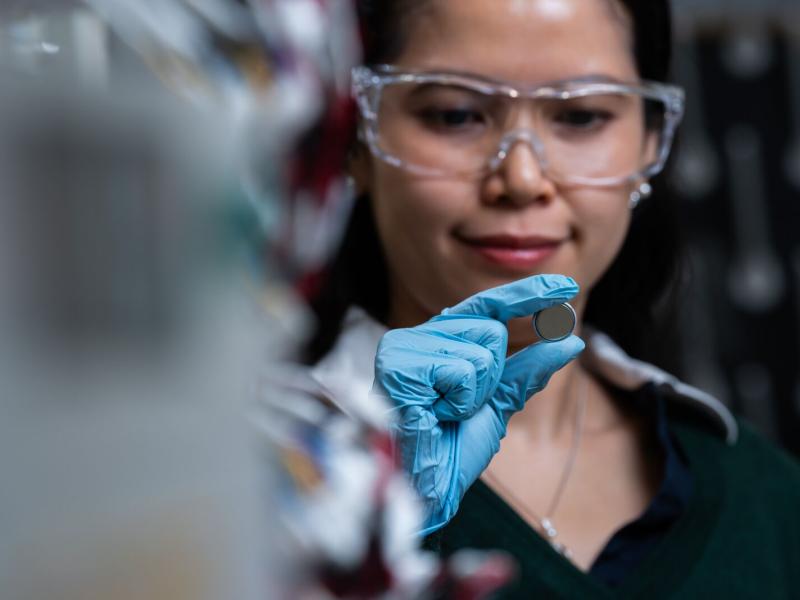

From Molecules to Batteries and Beyond: Celebrating PNNL’s Energy Storage Legacy

November 24, 2025

Energy Department Launches ‘Genesis Mission’ to Transform American Science and Innovation Through the AI Computing Revolution

Subscribe

to receive PNNL

news by email:

Latest Stories

107 results found

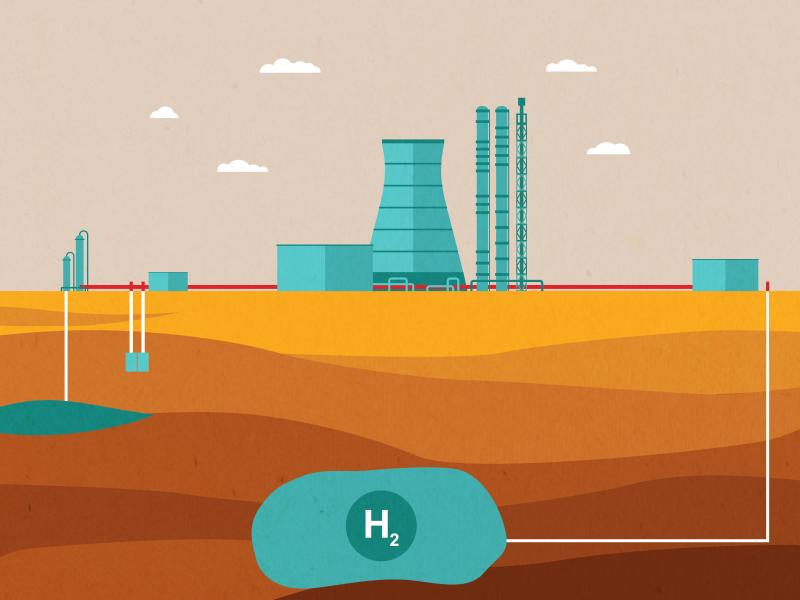

Filters applied: Hydrogen & Fuel Cells, Vehicle Electrification, Fusion Energy Science