CDI Project: Phase-Field Modeling of Microstructure Evolution in Selective Laser Sintering Process

Return to Additive Manufacturing Use Case

PI: Yulan Li

Project Team: Scott Muller

Project Term: October 2019 to September 2020

Key Science Questions:

- How do the dominant sintering mechanisms depend on selective laser sintering (SLS) parameters?

- How do SLS parameters affect the pore structure, porosity, and property?

- How do aging time and temperature affect pore structure evolution?

Project Description: The goal of this project is to develop a modeling capability in additive manufacturing (AM) for improving the understanding of sintering mechanisms in AM processing and predicting the effect of AM processing parameters on the microstructure evolution kinetics and final porosity and properties.

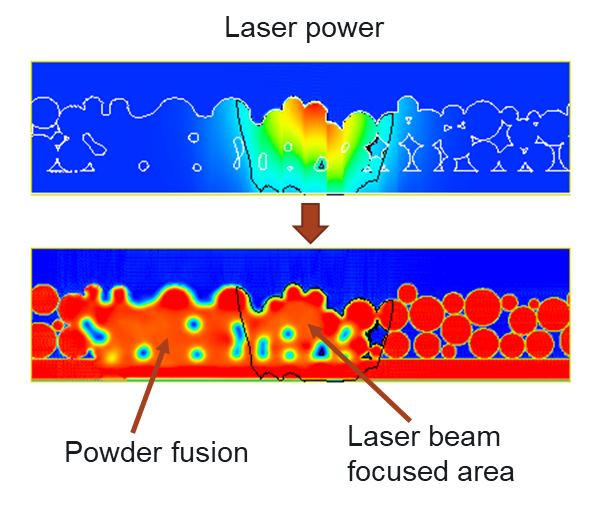

The current focus is to enhance the model capability by integrating the scanning laser power, the generation of a powder layer, and gravity effect, etc. and model the relationships between additive manufacturing (in particular, the selective laser sintering) process parameters and feedstock to the resulting microstructure (process to structure) for selective laser sintering (SLS) printed Nylon 12 components. To this end, the project team uses a phase-field approach, which can account for changes in the phase/state boundaries as the powder is sintered or melted into a solid.

Progress to date includes a ready-to-use phase-field model of microstructure evolution during SLS. The model considers the sintering mechanisms, including surface and bulk diffusion, evaporation and condensation, particle translation and rotation, and partial melting. It can also simulate the temperature distribution from a laser beam and its effect on sintering dynamics. Simulation results demonstrate the model’s capability to investigate the effect of sintering parameters on sintering kinetics and microstructures.