Carbon Mineralization Laboratories

Supporting commercial-scale geologic storage

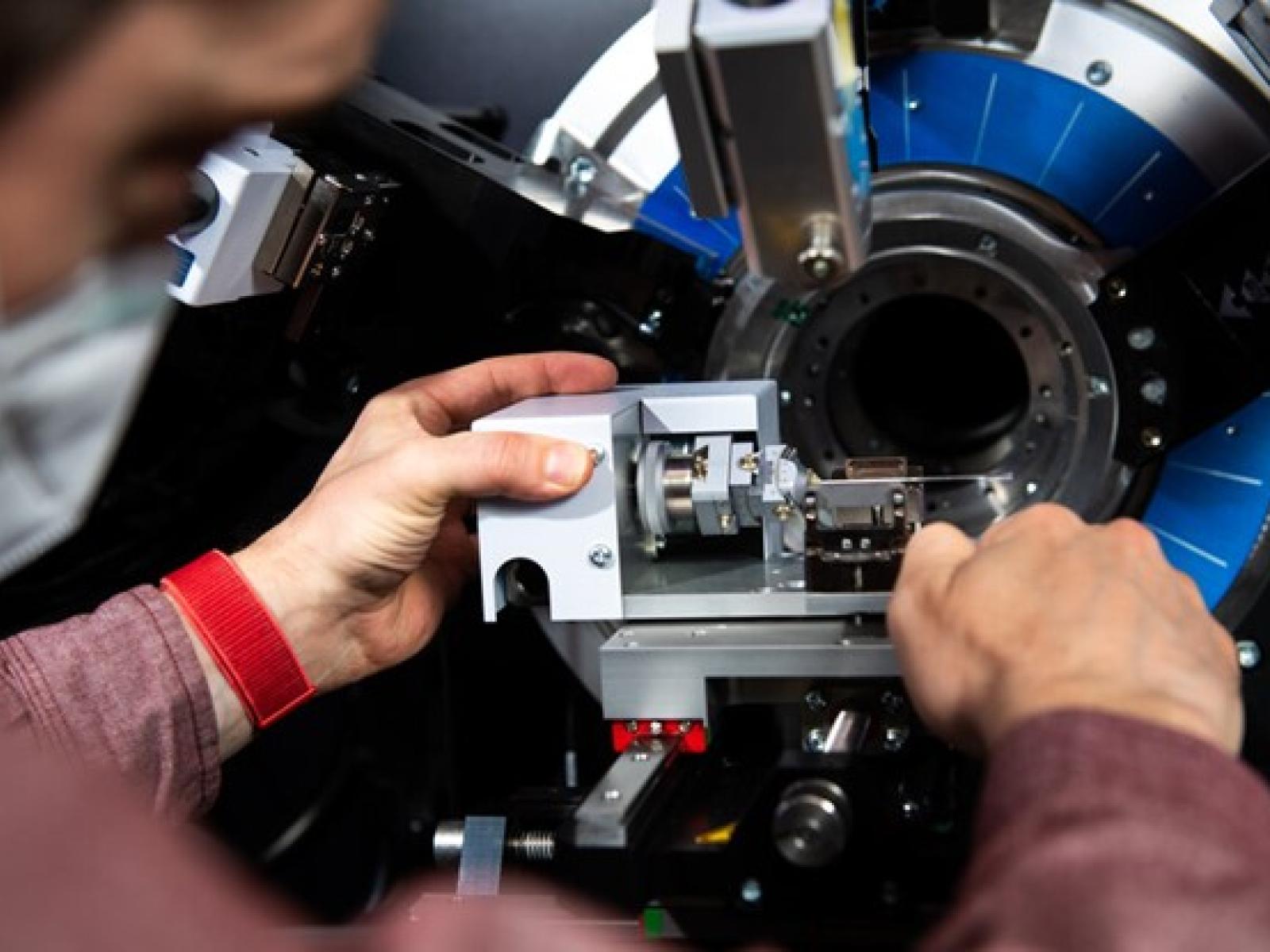

The new Bruker D8 Discover A25 X-ray diffractometer is set up like no other instrument in the Western Hemisphere. It is used to determine the crystal structures of materials, including powders and thin films. The custom-built high-pressure cells allow for in situ time-resolved monitoring of fluid-solid transformations at extreme temperatures and pressure relevant to the subsurface and technologic processes. This “cooking while looking” approach reveals intermediate and/or short-lived phases and structural changes/transformations, allowing for determination of precise reaction rates. The new in operando battery cell enables researchers to monitor electrolyte-based and solid-state batteries while in operation, helping produce energy storage devices with greater capacity and longevity.

(Photo by Andrea Starr for Pacific Northwest National Laboratory)

Pacific Northwest National Laboratory (PNNL) has led research in applied subsurface science for over 50 years. Leveraging this diverse background, we support the Department of Energy's Office of Fossil Energy and Carbon Management Carbon Storage program with deep domain expertise and broad computational capabilities.

The PNNL carbon mineralization laboratories and capabilities in Richland, WA are helping with the acceleration of commercial-scale deployment of geologic CO2 storage coupled with critical mineral recovery and other frontier low-carbon technologies. Our scientists are working to deliver solutions for real-time imaging of the subsurface by bringing together domain experts in geophysics, geochemistry, data science, and high-performance computing.

Instruments/Equipment Include:

- X-Ray Diffraction at Extreme Conditions: This instrument allows researchers to determine the mineralogy and structure of materials, including the quantification of different phases in mixtures. World-unique reactors that operate at elevated temperature and pressure (up to 800°C and 210 bar) allow researchers to probe carbon mineralization in real time at relevant subsurface conditions, determining reaction rates and detecting mysterious intermediate phases.

- High-Pressure Reactors: PNNL’s carbon mineralization capabilities rely on a deep bench of nearly 50 reactors of varying volumes, geometries, sampling accessories, and windows to react rocks with water and CO2 at subsurface-relevant pressures and temperatures.

- Seismic Core Test: This “miniature earthquake machine” allows researchers to determine the low-frequency behavior of rocks containing pressurized fluids and the information benchmarks and ground-truth technologies used for subsurface geophysical monitoring and mapping.

- Reactive Transport Geochemical Modeling: Using field- and laboratory-derived data, these computer simulations predict the long-term fate and transport of fluids and metals in CO2 storage operations, answering key questions related to permitting and optimizing efficient permanent storage.

- X-ray Microtomography: This capability is used to non-destructively image the internal structure of rocks, helping researchers quantify the distributions of pores (voids), pore throats, segmented mineral phases, and fluids.

- Petrographic Microscopes: The three polarized light microscopes with integrated digital cameras are used to identify minerals and their distributions in rock samples that can be thin slices, drill cuttings, or larger core fragments. One of the microscopes is portable and is also used for demonstrations during community and stakeholder engagement.

- Micro X-Ray Fluorescence: This spectrometer system allows for non-destructive elemental analysis and chemical imaging of large sample areas with high spatial resolution. Micro-X-ray fluorescence supports carbon sequestration efforts by spatial chemical analysis of rock samples, core sections, and crushed powders to uncover elemental fluxes, provide trace element detection, and quantitative mineralogical assessment.

- X-Ray Photoelectron Spectroscopy: This is a surface sensitive, non-destructive characterization technique that provides quantitative surface composition and oxidation state analysis. X-ray photoelectron spectroscopy supports the carbon storage platform by providing quantitative chemical speciation of critical elements, enabling a robust geochemical understanding of mineral systems.

- Thermogravimetric Analyzer with Mass Spectrometry: This workhorse instrument is used to quantify carbonate mineral content in samples by heating up a sample on a sensitive microbalance, measuring the weight loss during material decomposition caused by CO2 leaving the sample and flowing into the mass spectrometer. Recent advances have pushed the quantification limits of carbonate in samples to <100 parts per million.

- Electron Microscopy Suite: Carbon storage researchers also use the diverse micro- and nano-analytical techniques (including ion milling, electron diffraction, and transmission electron microscopy) at PNNL to determine chemistry, morphology, mineralogy, and orientations of samples—even imaging carbonation products on an atom-by-atom basis.

- Flow-Through Dissolution Reactors: This dynamic reactor system enclosed in an oxygen-free glove-bag environment helps researchers evaluate rock dissolution rates and products as a function of temperature and pH.