WSU Students Work to Improve Sample Analysis for International Nuclear Safeguards

Students design and build two distillation systems that use less energy and water than conventional systems and learn new skills in the process

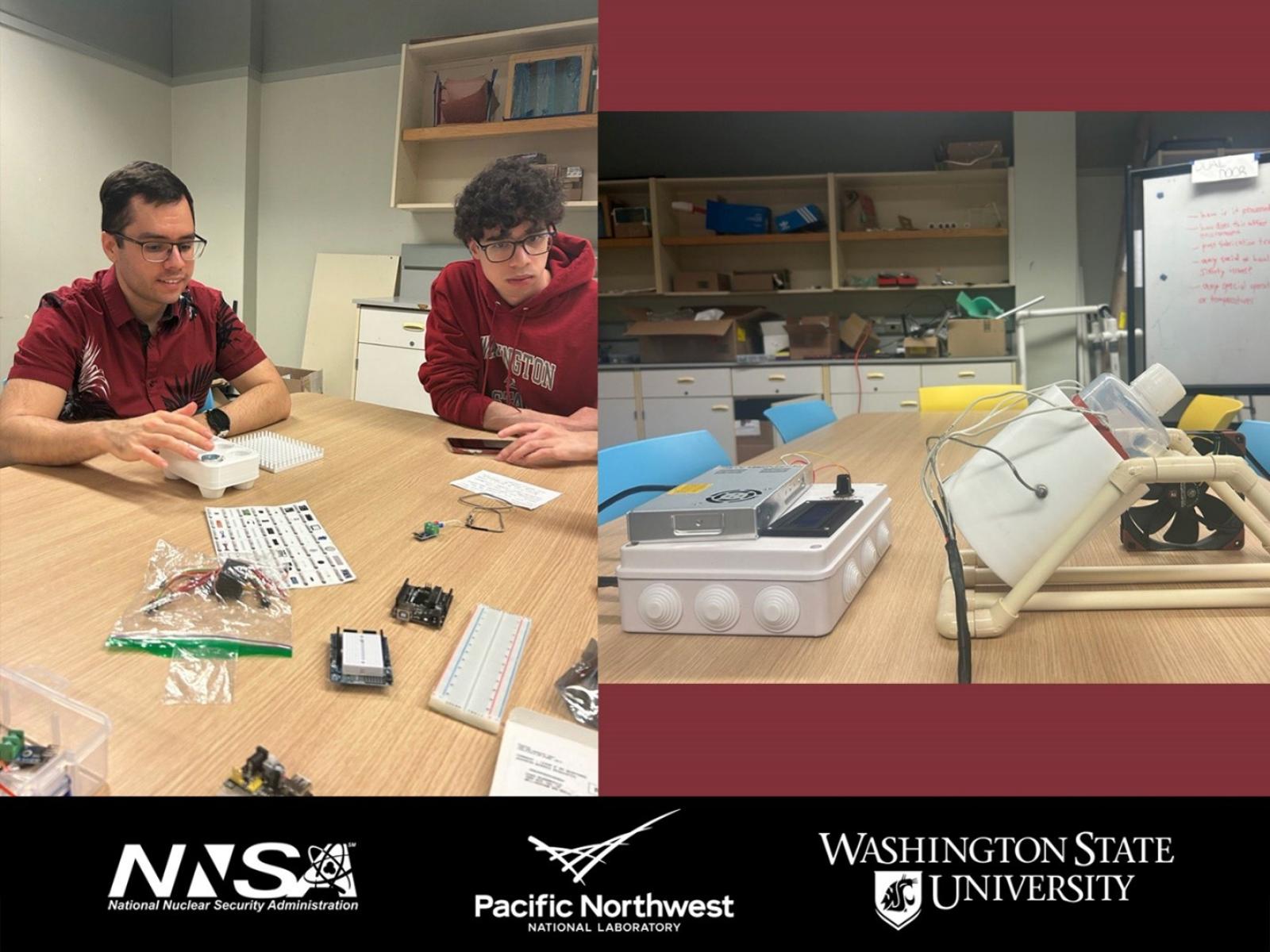

On the left, WSU engineering students Raphael Torres and Sebastian Cordero work on electronics to control the distillation systems they designed and fabricated (on the right) for an NNSA-sponsored project to address a challenge in nuclear safeguards research at Pacific Northwest National Laboratory.

(Shannon Colson | Pacific Northwest National Laboratory)

During a recent virtual presentation of their capstone project to professors and Pacific Northwest National Laboratory (PNNL) mentors, a team of Washington State University (WSU) students delivered a project designed to improve preparation of environmental samples for analysis at PNNL. The project was sponsored by the National Nuclear Security Administration (NNSA) Office of International Nuclear Safeguards under its Human Capital Development Program. Through this program, NNSA and PNNL have been partnering with WSU engineering students for more than 10 years to address research challenges in the nuclear nonproliferation realm and develop the next generation of experts.

The students worked the project while enrolled in the Industrial Design Clinic at WSU. This semester, researchers challenged the students to design two distillation systems that use less energy and water than conventional systems and would help PNNL prepare the small environment samples it analyzes.

The team of mechanical engineering students—Sebastian Cordero, Eudoxie Hudry, Ben Matthes, Chad Nunamaker, Raphael Torres, and Evan Walker—faced design challenges, which led them to teaching themselves new skills in electronics and chemistry.

“Adaptability is key—it requires you to learn something new,” said Raphael Torres.

“You also need to learn to ask the right questions up front to make sure you understand the problem you are trying to solve,” added Evan Walker.

The student team designed the system, ordered materials, set up electronics, arranged for manufacture of unique parts through the WSU fabrication shop, and assembled and tested the distillation system—on time and under budget.

The first system consists of two 1-liter plastic bottles that have a common top lid. One bottle is heated, sending vapor through the lid and into the other bottle, which is cooled by a small fan that condenses the vapor. The second system is a tray that can hold and heat six small vials. The tops of the vials collect the vapor, and a cooling pad helps condense the vapor at the top of the vials. Electronics control the duration of heating to the small apparatuses to help with energy savings. The ability to handle smaller sample sizes reduces the possibility of contamination. WSU sent PNNL the design documents and hardware at the conclusion of the semester.

“This is an exciting project; it will enable us to reduce sample sizes and contamination, which is a substantial factor in diminishing uncertainties for International Atomic Energy Agency work,” said PNNL Earth scientist Eirik Krogstad.

PNNL mentors for this project included Eirik Krogstad, Kelly McHugh, Mark Mitchell, Alexis Krueger, Ji-Hye Seo, and Patrick Valdez.

Published: October 9, 2023