Digital Twins for Hydropower

Digital Twins for Hydropower

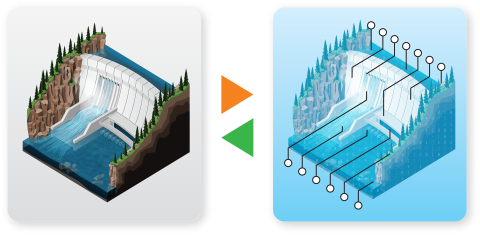

The Department of Energy Water Power Technologies Office has developed the Digital Twins for Hydropower framework to create a virtual platform to accelerate technology development for the hydropower industry.

Illustration by Chris DeGraff | Pacific Northwest National Laboratory

Lab-Level Communications Priority Topics

Grid