Polymer and Composite Materials Laboratory

Pacific Northwest National Laboratory (PNNL) scientists and engineers develop innovative, energy-efficient materials and processes to enhance durability, performance, and environmental compatibility for next-generation technologies.

Physical Science Laboratory and 3410 Material Science and Technology Laboratory

Richland, WA

United States

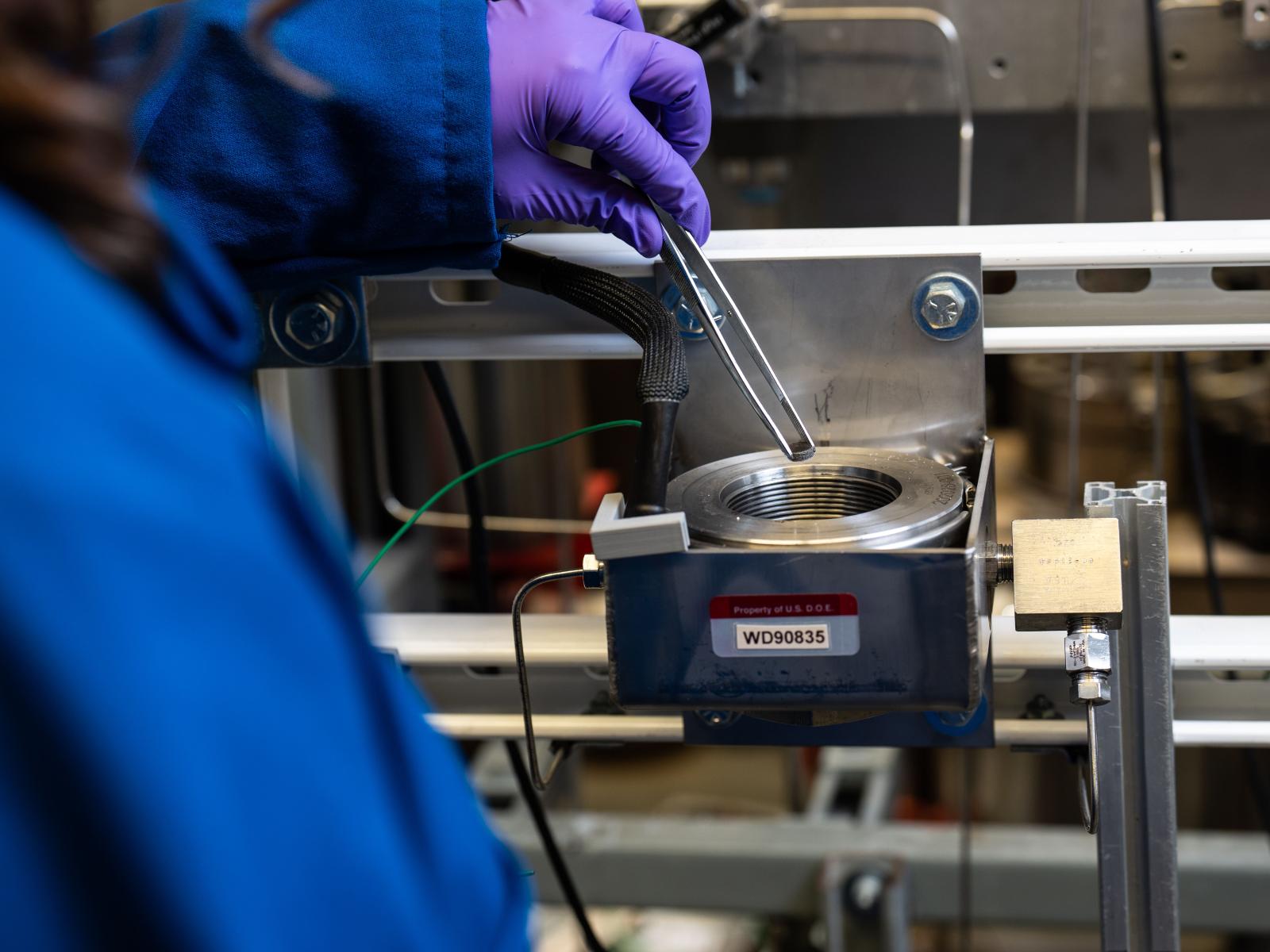

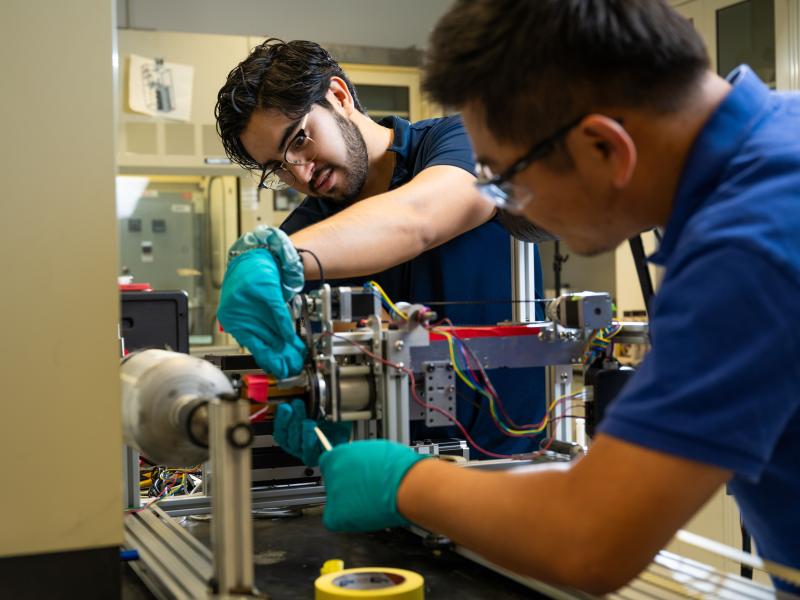

Researchers, including Areesa Trevino, a postmaster’s research associate in the PNNL Applied Materials and Manufacturing Research group, conduct in-situ mechanical tests on natural gas pipeline materials to understand the effects of blending hydrogen into the U.S. natural gas infrastructure.

(Photo by Andrea Starr | Pacific Northwest National Laboratory)

Located within multiple interconnected labs on the PNNL-Richland campus, the Polymer and Composite Materials Laboratory comprises staff who collaborate with various organizations on advanced materials research. Offering support to academia, industry partners, Department of Energy (DOE) national laboratories, and others, the Laboratory's research focuses on the fabrication, testing, and characterization of polymers and reinforced composites to enhance durability, performance, and environmental compatibility.

Researchers specialize in innovative recycling and upcycling of carbon fiber composites, environmental degradation analysis, and hydrogen durability testing. Capabilities include low-cost and high-throughput composite manufacturing, rubber compounding, and adhesive bonding of multi-material systems. Through experimental and computational modeling, experts also investigate energy absorption, impact resistance, and damage behavior to develop next-generation materials, including hybrid composites with bio-based and geo-based fibers.

Fabrication, Testing, and Characterization

Developing Innovative, Energy-Efficient Materials and Processes

- Recycling or upcycling of carbon fiber–reinforced composites and plastics

- Environmental degradation of materials

- Life cycle and hydrogen permeation analysis

- Hydrogen compatibility and environmental durability testing, including cryogenic testing in liquid H2 conditions

- Studies on energy absorption and impact resistance of plastics and composites

- Experimental and computational modeling of the damage, fracture, and nonlinear behavior of polymers and reinforced composites

Enhancing Durability, Performance, and Environmental Compatibility

- Low-cost and specialized composite manufacturing methods (e.g., pultrusion)

- Prototype-scale composite fabrication

- Rubber formulation and compounding

- Adhesive joining of multi-materials

- Polymer synthesis, formulation, and surface chemistry modification

- Hybrid structural composites and natural fibers (bio-based and geo-based)

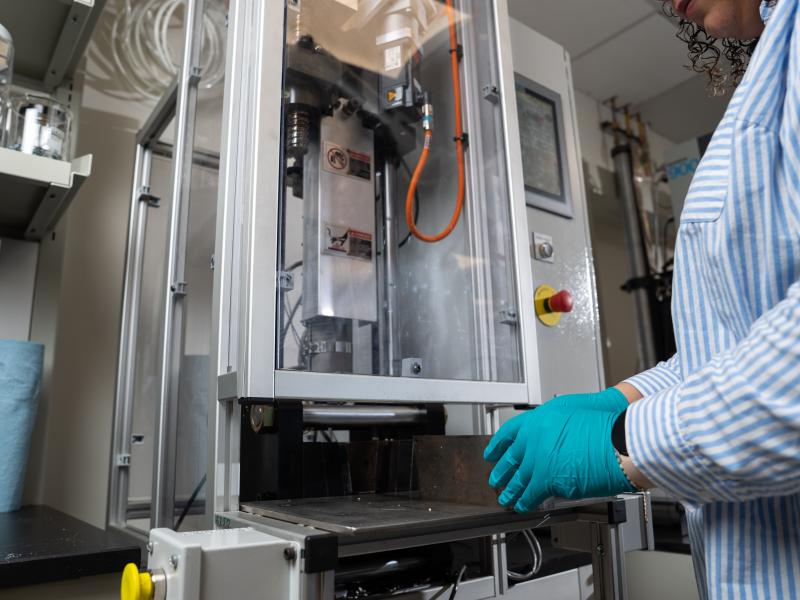

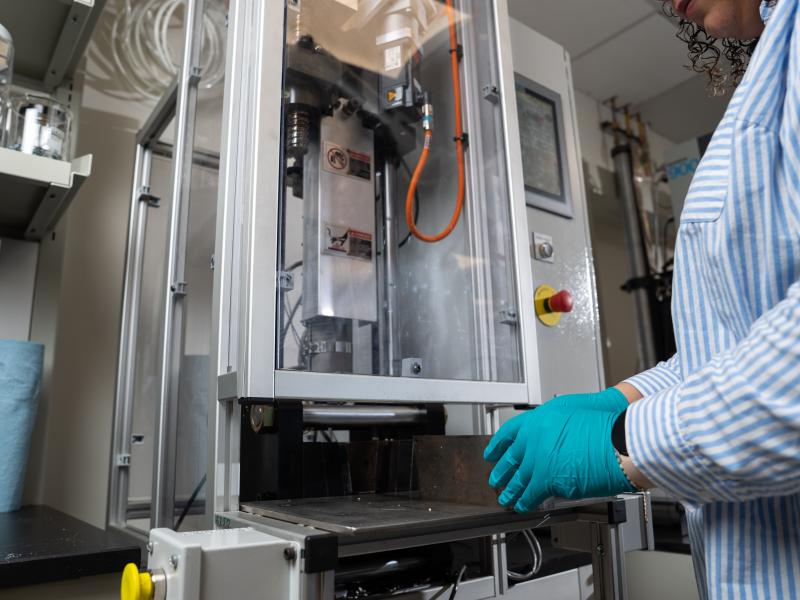

Dounia Boushab, a postdoctoral research assistant in the PNNL Applied Materials and Manufacturing Research group, uses injection molding to up-cycle industrial waste into high-value construction materials.

(Photo by Andrea Starr | Pacific Northwest National Laboratory)

Researchers, including Yao Qiao, a materials scientist in the PNNL Applied Materials and Manufacturing Research group, and Cesar Moriel, a previous intern in the PNNL Applied Materials and Manufacturing Research group, established a filament winding protocol for fabricating subscale composite–overwrapped pressure vessels to advance the understanding of the process–property relationship and end-of-life recycling.

(Photo by Andrea Starr | Pacific Northwest National Laboratory)

Researcher Areesa Trevino uses a HAAKE PolyLab OS modular torque rheometer for formulating and compounding elastomers with enhanced material performance for hydrogen applications.

(Photo by Andrea Starr | Pacific Northwest National Laboratory)

A sample in the tensile creep, part of the hydrogen pressure vessel that tests the integrity and strength of materials.

(Photo by Andrea Starr | Pacific Northwest National Laboratory)

Full Spectrum of Capabilities and Equipment

Testing and Material Characterization | Manufacturing Techniques | Material Processing and Compounding | Surface Treatment and Coating | Advanced Instruments |

|---|---|---|---|---|

|

|

|

|

|