Featured Stories

February 17, 2026

PNNL Powers Biotechnology, Grid Operations, Nuclear Science Through Genesis AI for Science Mission

February 11, 2026

Earthquake Data Provide Solid Footing for AI Foundation Science Model

January 27, 2026

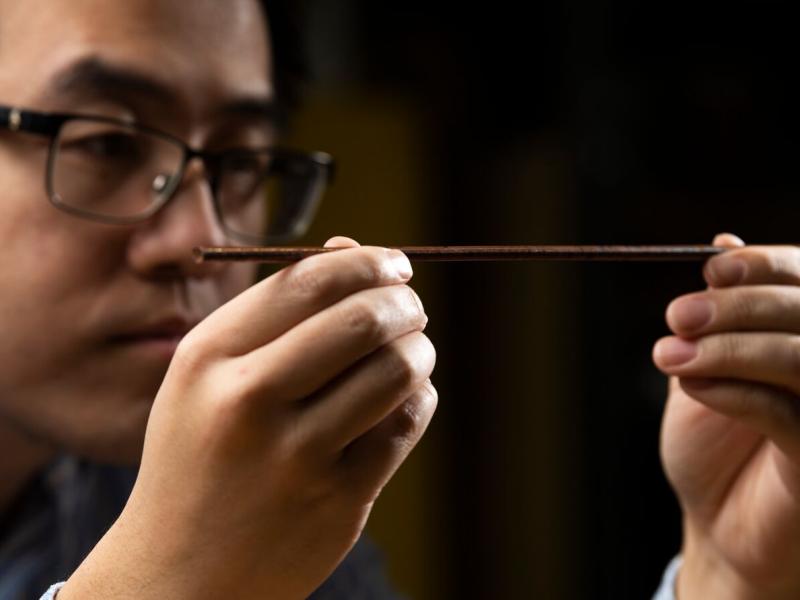

Nuclear Waste Transformed: PNNL Scientists Solidify History With Glass

January 29, 2026

New Minds for New Mines

Subscribe

to receive PNNL

news by email:

Latest Stories

42 results found

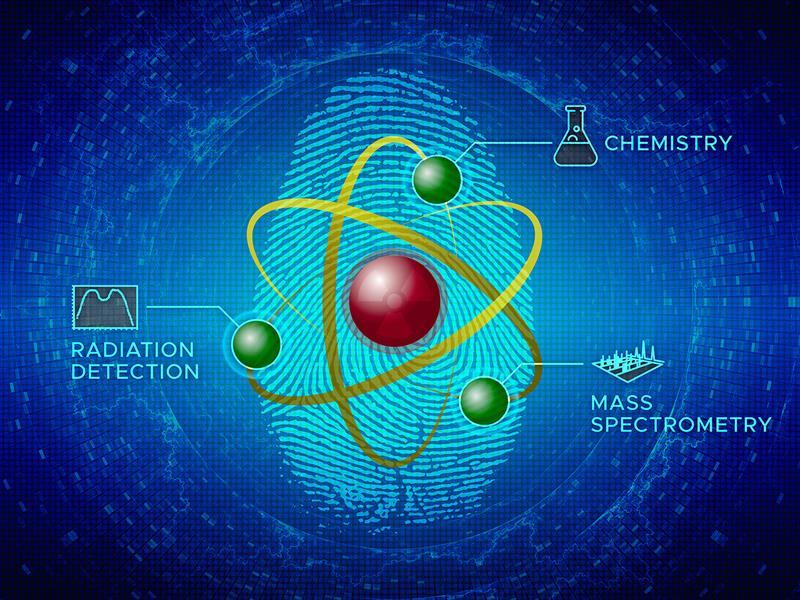

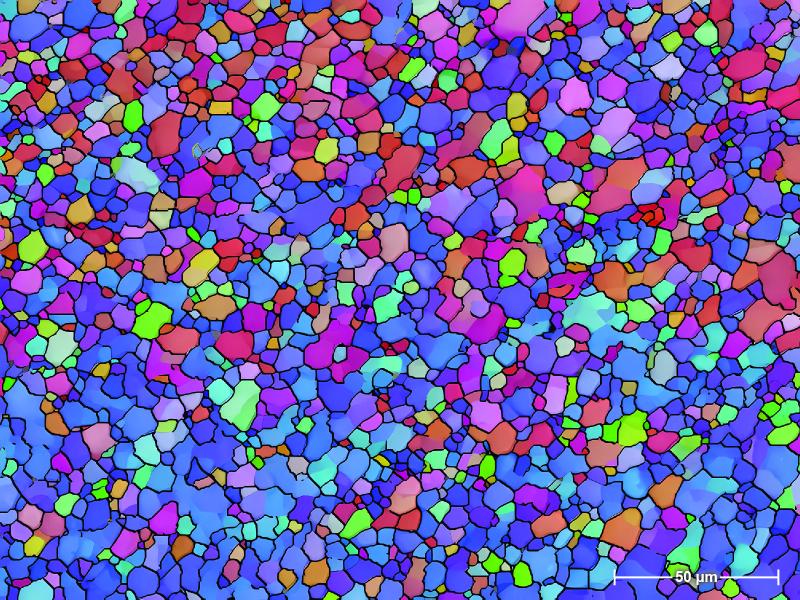

Filters applied: Lightweight Materials, Building Energy Asset Score, Nuclear Forensics